Layered lithium nickel composite oxide powder and process for producing the same

A technology for composite oxides and manufacturing methods, applied in nickel compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of insufficient battery performance in rate characteristics and output characteristics, and achieve excellent initial charge and discharge characteristics and high-speed discharge characteristics Effects of excellent, excellent rate characteristics and output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] With Ni(OH) 2 , Mn 3 o 4 、Co(OH) 2 As a starting material, it was weighed so that the molar ratio of Ni:Mn:Co was 0.33:0.33:0.33, and pure water was added thereto to prepare a slurry. The slurry was pulverized until the average particle size of the solids was 0.15 μm by stirring with a circulating medium agitation type wet pulverizer (Dyno Mill KDL-A type manufactured by Synmasu Entera-Plaise Co., Ltd.).

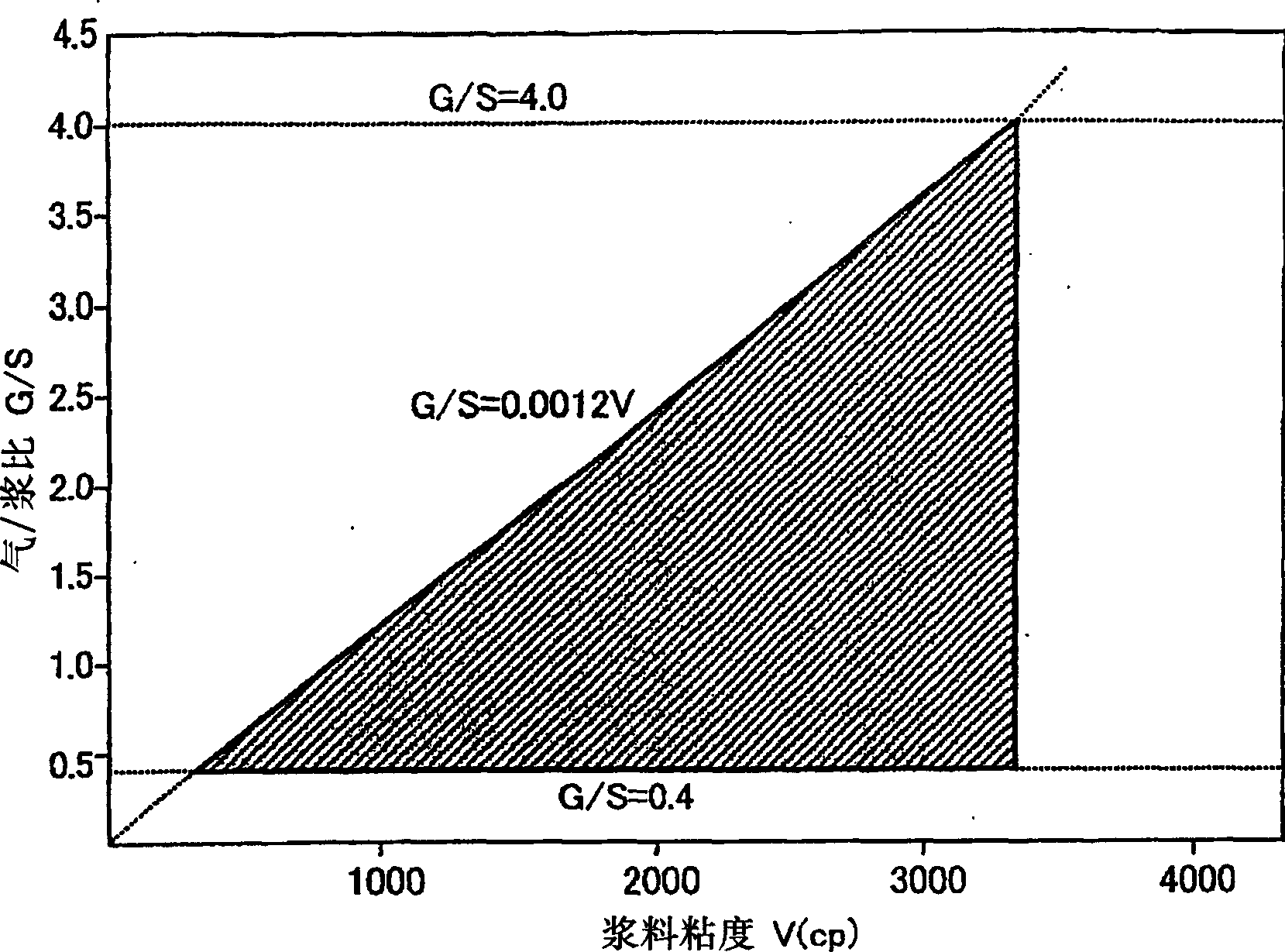

[0110] Next, this slurry (solid content: 17% by weight, viscosity: 810 cp) was spray-dried using a two-fluid nozzle type spray dryer (manufactured by Okawara Chemical Equipment Co., Ltd.: LT-8 type). The spray nozzle used is an external mixing nozzle. Among the concentric nozzles, the inner side is the slurry outlet, and the outer side is the pressurized gas outlet. The outer diameter of the nozzle is 3mm, the diameter of the slurry outlet is 2.3mm, and the pressurized gas flow The gap of the outlet is 0.2mm, and the cross-sectional area is 1.76mm 2 . At this ti...

Embodiment 2

[0114] Use a slurry whose average particle size of solids is pulverized to 0.17 μm, and set the solids content of the slurry to 15.5% by weight, viscosity to 960 cp, and dry gas introduction amount G to 45 L / min in spray drying by a spray dryer. , The gas linear velocity is 426m / sec, the slurry introduction amount S is 39g / min (gas / slurry ratio G / S is 1.15), the drying inlet temperature is 90°C, and the powder is mixed with the pulverized LiOH powder About 256 g was put into a rectangular crucible made of alumina, and baked at 950° C. for 12 hours under an air flow of 9 L / min. Then pulverize and bake at 950°C for another 12 hours. In addition, the same operation as in Example 1 is performed to obtain a layered structure composed of Li 1.05 Ni 0.33 mn 0.33 co 0.33 o 2 lithium nickel manganese cobalt composite oxide powder.

[0115] Table 1 shows the values of the physical properties of the powder measured by the same method as in Example 1.

Embodiment 3

[0117] Use a slurry whose average particle size of solids is pulverized to 0.13 μm, and set the solids content of the slurry to 16% by weight, viscosity to 900 cp, and dry gas introduction amount G to 30 L / min in spray drying by a spray dryer. , the gas linear velocity is 284m / sec, the slurry introduction amount S is 35g / min (the gas / slurry ratio G / S is 0.86), the drying inlet temperature is 90°C, in addition, the same operation as in Example 1 is obtained to have a layered structure The composition is Li 1.05 Ni 0.33 mn 0.33 co 0.33 o 2 lithium nickel manganese cobalt composite oxide powder.

[0118] Table 1 shows the values of the physical properties of the powder measured by the same method as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com