Super high vacuum system sample feeding apparatus

A new type of ultra-high vacuum technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of high production cost, complex structure, small room for modification, etc., and achieve good compatibility, simple and effective overall structure, and processing and manufacturing Use easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

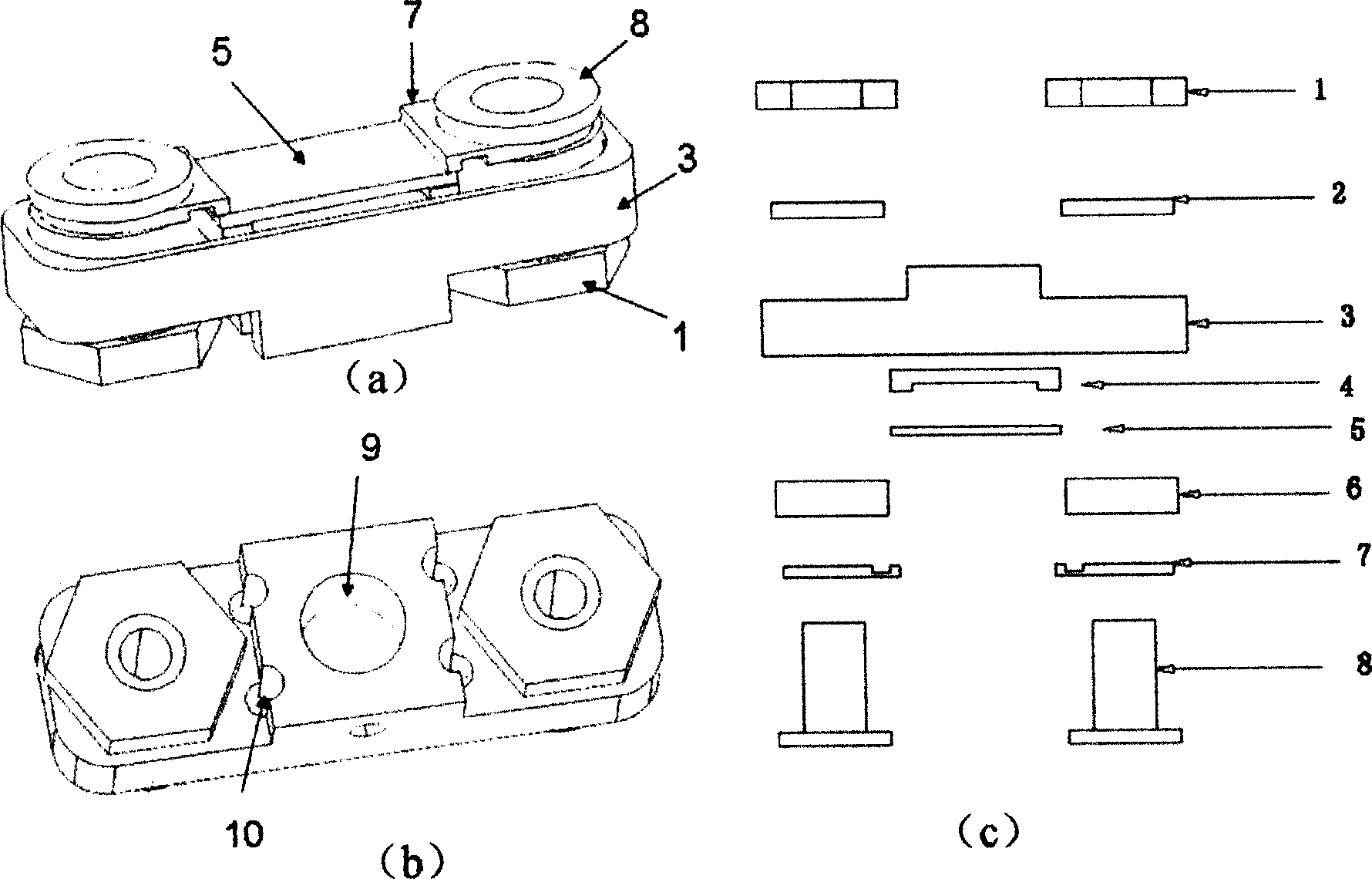

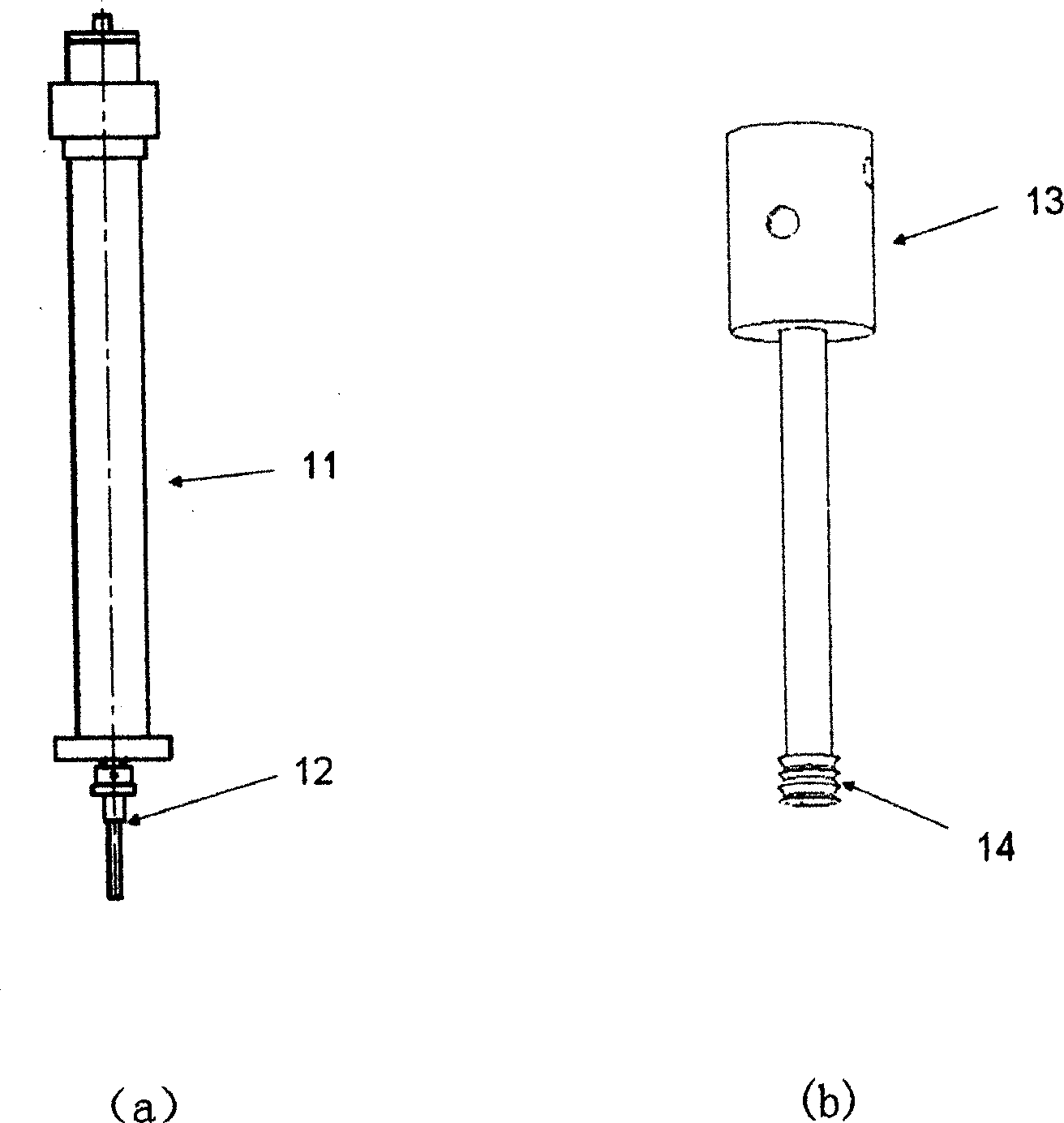

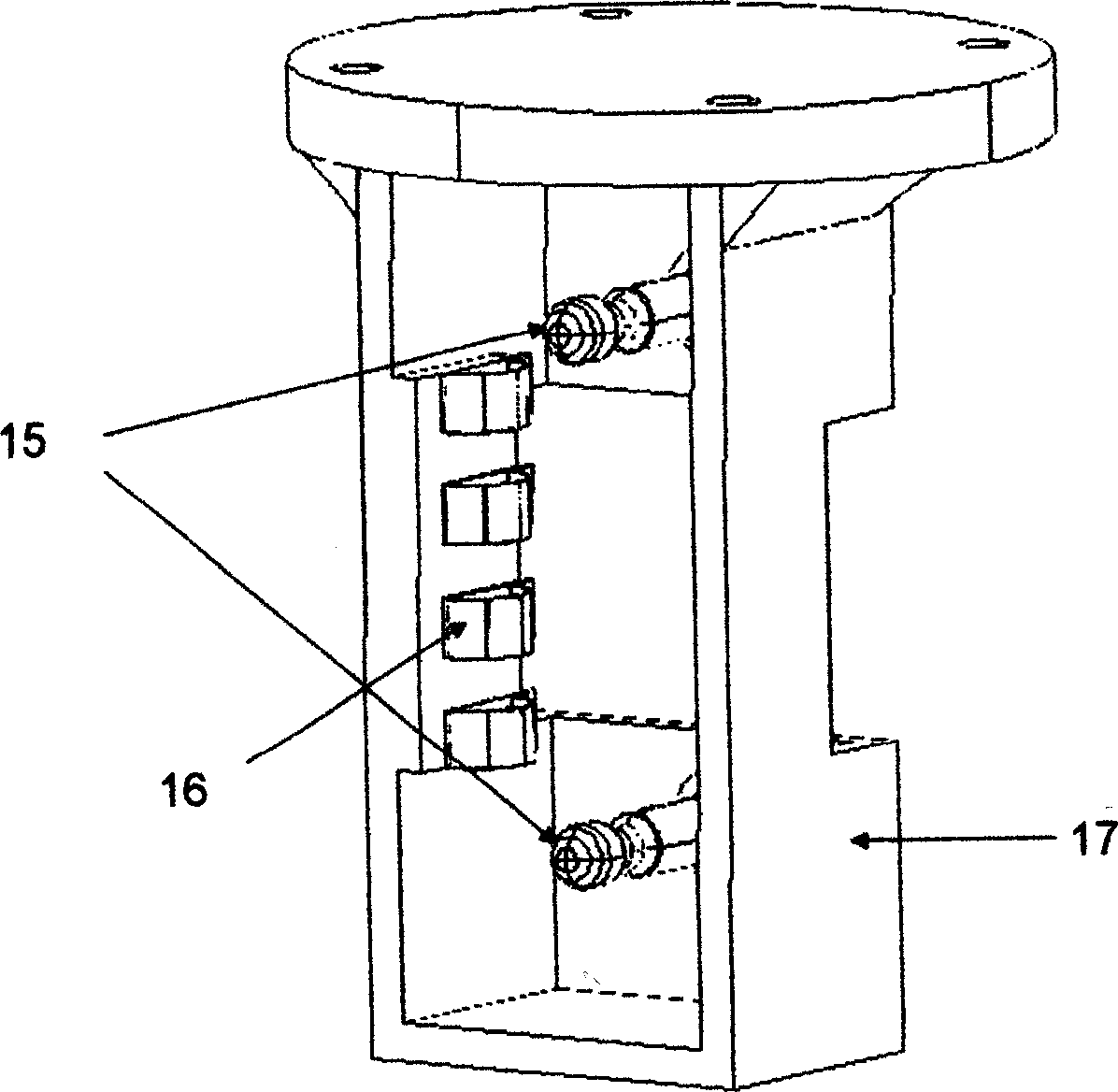

[0021] The present invention comprises: sample holder, sample transfer rod and sample receiving table, such as figure 1 As shown in a, b, and c, the sample support includes a rectangular parallelepiped molybdenum support 3, two hollow molybdenum screws 8 and an insulating lining 4. There are through holes at both ends of the molybdenum support 3 for installing the molybdenum screw 8 and the molybdenum support 3. There is a boss in the middle part of the lower part, and the boss has a threaded hole 9. The molybdenum screw 8 is fixed by the molybdenum nut 1 and the molybdenum bracket 3. The lower end of the nut of the molybdenum screw 8 is pierced with the first electrode 7, which is used to connect with the insulating lining. 4 together to fix the sample 5 and introduce current to the sample 5, between the first electrode 7 and the molybdenum support 3 and between the nut 1 and the molybdenum support 3 are respectively provided with insulating rings 2, 6, and the molybdenum supp...

Embodiment 2

[0023] Such as Figure 4 As shown in a, the difference between this embodiment and embodiment 1 is that a second electrode 20 and a heating resistor 19 are arranged in sequence between the sample 5 and the insulating lining 4, and a heating resistor 19 is arranged between the second electrode 20 and the molybdenum support 3. Another insulating ring 18 .

[0024] For high resistance (insulating) samples, direct heating with electric current is obviously not possible. In this embodiment, double-layer metal electrodes are used for high-resistance samples, the first electrode 7 is only used to fix the sample 5 , and the second electrode 20 is used to clamp the heating resistor 19 . When the current is passed through the two ends of the second electrode 20, the heating resistor 19 becomes hot, which indirectly heats the sample 5.

Embodiment 3

[0026] Such as Figure 4 As shown in b, the difference between this embodiment and embodiment 2 is that an insulating spacer 21 is provided between the sample 5 and the second electrode 20, and the first electrode 7 can be replaced by an insulator.

[0027] For the metal sample, considering that some occasions have special requirements for the grounding of the sample 5, one of the first electrodes 7 (two symmetrical ones) of the fixed sample 5 is replaced with an insulator, and the sample 5 and the second electrode 20 are connected simultaneously. Insulation, just can avoid electric current to pass through sample 5 and cause short circuit when heating.

[0028] In addition, it is also possible to use the Figure 5 The structures shown in a and b. Such as Figure 5 As shown in a, two unconnected metal pads 22 are padded on the insulating lining 4 of the sample holder, and the shapes of the two metal electrodes 7 used to clamp the sample 5 can also be changed accordingly, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com