Corrosion resistance excellent steel for ship

A corrosion-resistant technology for ships, applied in the field of steel for ships, to achieve excellent durability, improved durability, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

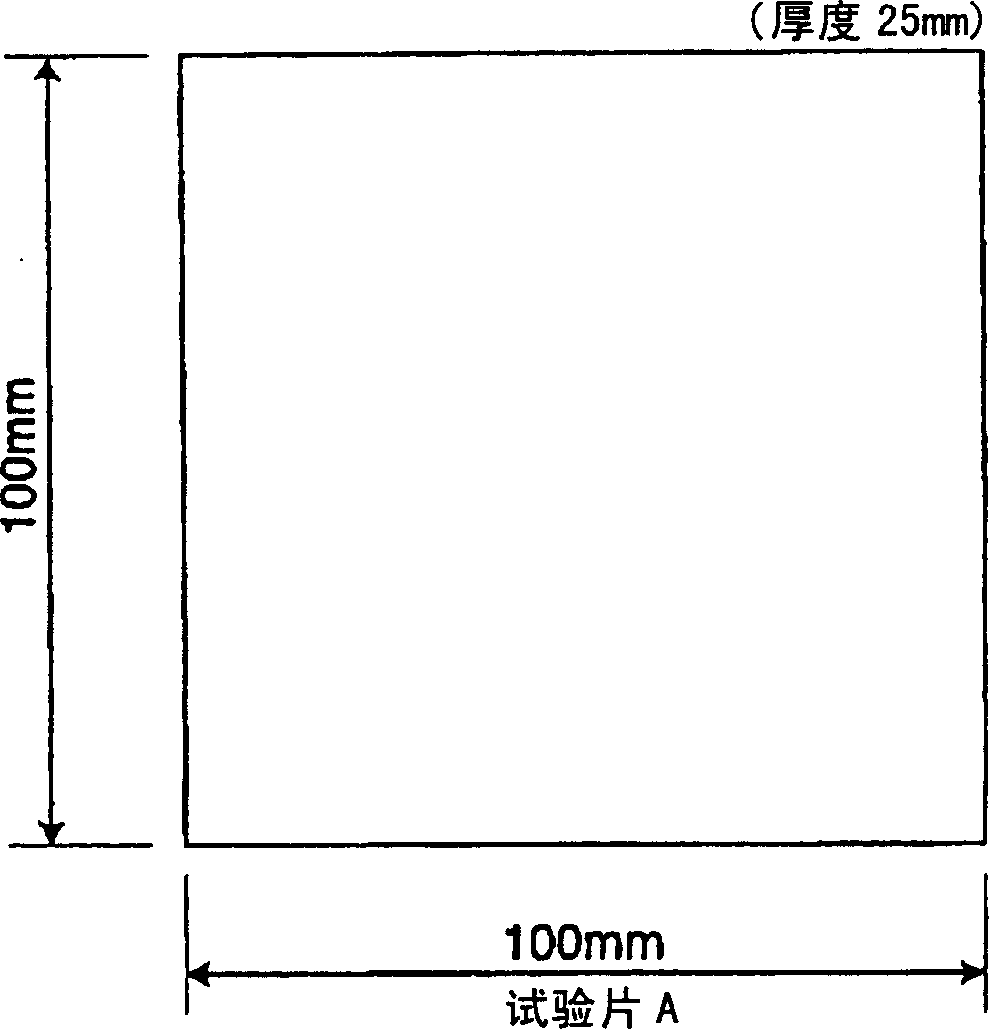

[0064] Steel materials with the chemical compositions shown in Tables 1 and 2 below were smelted in a converter, and various steel plates were produced by continuous casting and hot rolling. The obtained steel plate was cut, the surface was ground, and finally a test piece (test piece A) having a size of 100×100×25 (mm) was prepared. figure 1 The external appearance shape of the test piece A is shown.

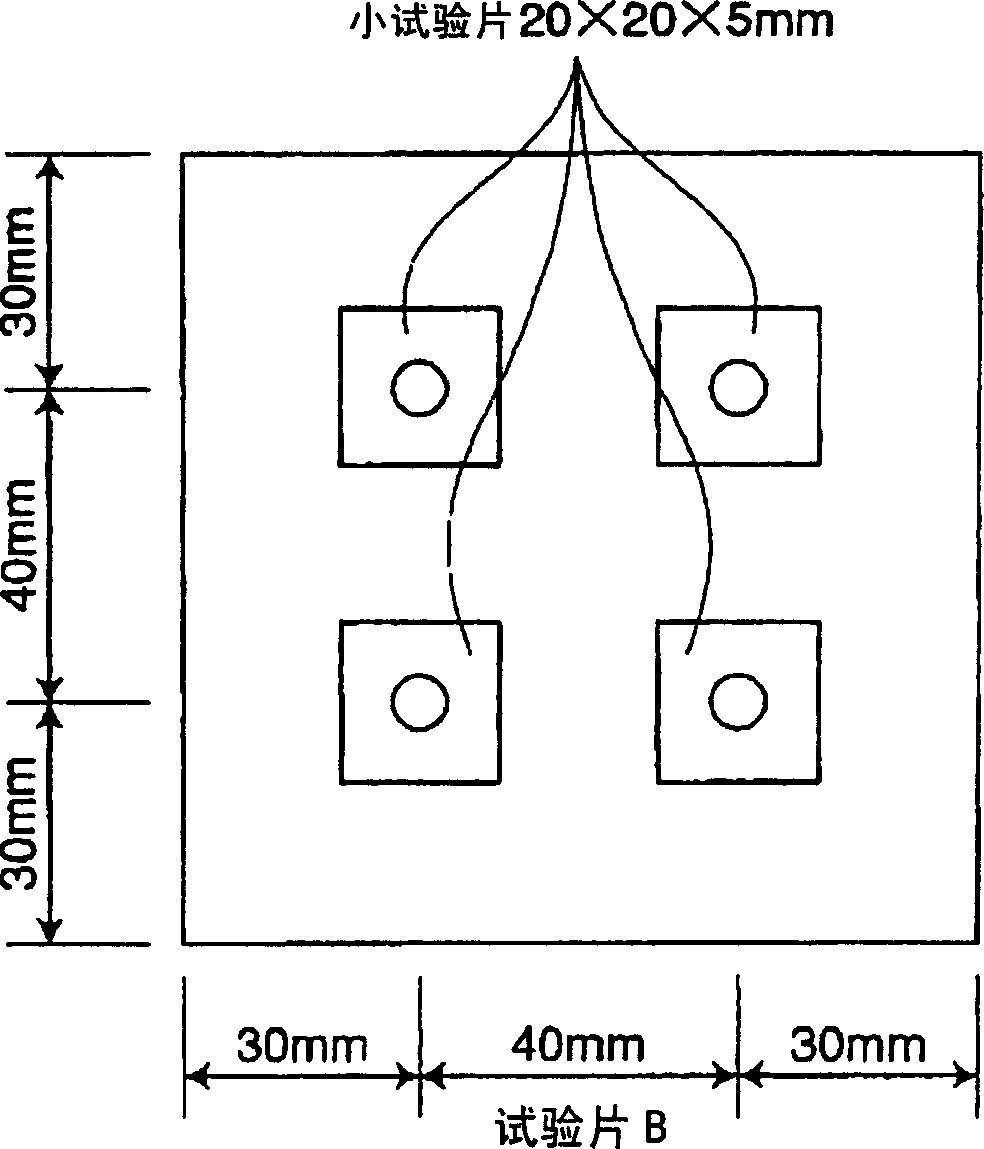

[0065] In addition, if figure 2 As shown, four small test pieces of 20×20×5 (mm) were brought into contact with a large test piece of 100×100×25 (mm) (the same as the above-mentioned test piece A), and a test piece B in which a crack was formed was produced. . The small test piece and the large test piece for crack formation are steel materials with the same chemical composition, and the surface finish is the same as that of the above-mentioned test piece A, which is defined as surface grinding. Then, a hole of Φ5 mm was made in the center of the small test piece, a screw h...

Embodiment 2

[0080] Steel materials with the chemical compositions shown in Tables 6 to 8 below were smelted in a converter, and various steel plates were produced by continuous casting and hot rolling. The obtained steel plate was cut, the surface was ground, and finally a test piece (test piece D) having a size of 300×300×25 (mm) was produced. Figure 4 The external appearance shape of the test piece D is shown.

[0081] In addition, if Figure 5 As shown, four small test pieces of 60 x 60 x 5 (mm) were brought into contact with a large test piece of 300 x 300 x 25 (mm) (the same as the above test piece D), and a test piece E with a crack was produced. . The small test piece and the large test piece for crack formation are steel materials with the same chemical composition, and the surface finishing is also the same as that of the above-mentioned test piece D, which is specified as surface grinding. Then, a hole of Φ10 mm was drilled in the center of the small test piece, a screw hole...

Embodiment 3

[0097] Steel materials having the chemical compositions shown in Table 13 below were smelted in a converter, and various steel plates were produced by continuous casting and hot rolling. The obtained steel plate was cut, the surface was ground, and finally a test piece G' having a size of 300×150×25 (mm) was produced. Subcede arc welding was carried out using welding consumables with the chemical composition shown in Table 14, and the joint test piece G ( Figure 7 ). In addition, the wire diameter of all welding materials is 4.8 mm, and the groove shape is V-shaped. The input heat is properly adjusted within the range of 1-10kJ / mm.

[0098] In addition, two small test pieces of 60 x 60 x 5 (mm) were brought into contact with the welded portion of test piece G to make contact with test piece H forming a crack ( Figure 8 ). The chemical composition of the small test piece for crack formation is the same as that of the base material of test piece D, and the surface finishin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com