Process for producing super high carbon steel

A technology of ultra-high carbon steel and production process, which is applied in the field of ultra-high carbon steel production process, and can solve problems such as increased energy consumption, high cost, and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Alloy composition (chemical analysis results, weight %): 1.17C-2.87Si-0.50Mn-1.58Cr-Fe;

[0041] (2) Spray forming to prepare billets

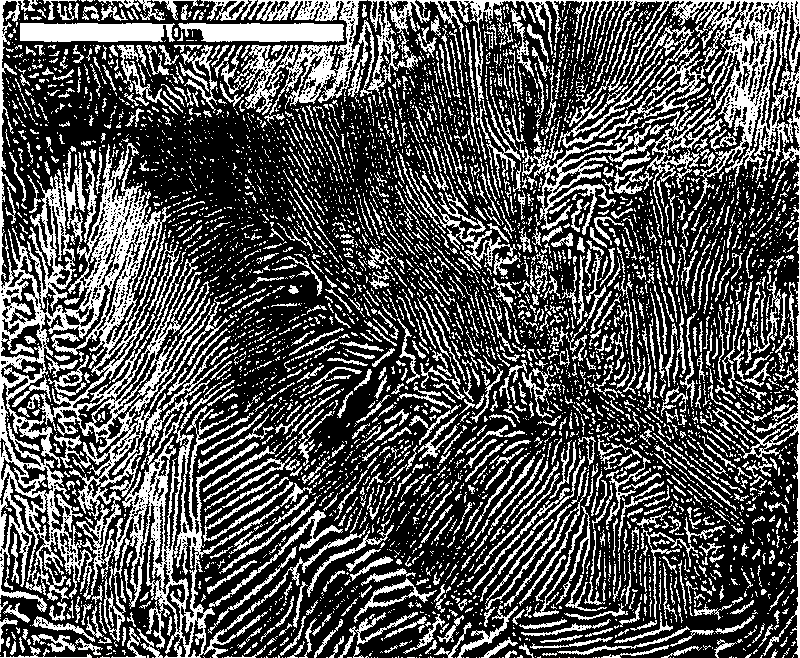

[0042] Put the master alloy material into the induction furnace crucible to melt, the superheat of the melt is about 150°C; the inner diameter of the catheter is φ4mm; the pressure of the atomizing gas (nitrogen) is 2.2MPa, and the distance between the atomizer and the collector substrate is about 360mm, substrate rotation speed is 10rpm; gas / melt flow ratio (G / M) is about 0.30M 3 / kg. Using the above process parameters to prepare a spray-formed billet, this block ultra-high carbon steel billet has excellent original structure (such as figure 1 Shown) so that it has excellent high-temperature deformation ability that general alloy materials do not have, so it can be subjected to large-scale thermal processing;

[0043] (3) Hot rolling of spray-formed blanks

[0044] A 15mm thick bar billet was cut from the spray-formed billet, a...

Embodiment 2

[0048] (1) Alloy composition

[0049] With embodiment 1;

[0050] (2) Spray forming process to prepare billets

[0051] With embodiment 1;

[0052] (3) Hot rolling of spray-formed blanks

[0053] Hot rolling process is with embodiment 1;

[0054] (4) Sheet metal heat treatment after hot rolling

[0055] After hot rolling, the sheet metal is immediately put into a heat treatment furnace whose temperature is set at 750°C for 150 minutes and then taken out for air cooling.

Embodiment 3

[0057] (1) Alloy composition (chemical analysis results, weight %): 1.17C-1.91Si-0.50Mn-1.56Cr-Fe;

[0058] (2) Spray forming process to prepare billets

[0059] With embodiment 1;

[0060] (3) Hot rolling of spray-formed blanks

[0061] Hot rolling process is with embodiment 1;

[0062] (4) Sheet metal heat treatment after hot rolling

[0063] After hot rolling, the sheet metal is immediately put into a heat treatment furnace whose temperature is set at 800°C for 150 minutes and then taken out for air cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com