Back scatter detector for high kilovolt X-ray spot scan imaging system

An imaging system and X-ray technology, applied in the field of backscatter detectors, can solve the problems of low ray absorption efficiency, moisture-susceptible price, low areal density, etc., and achieve the effects of reducing afterglow, improving sensitivity, and improving conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

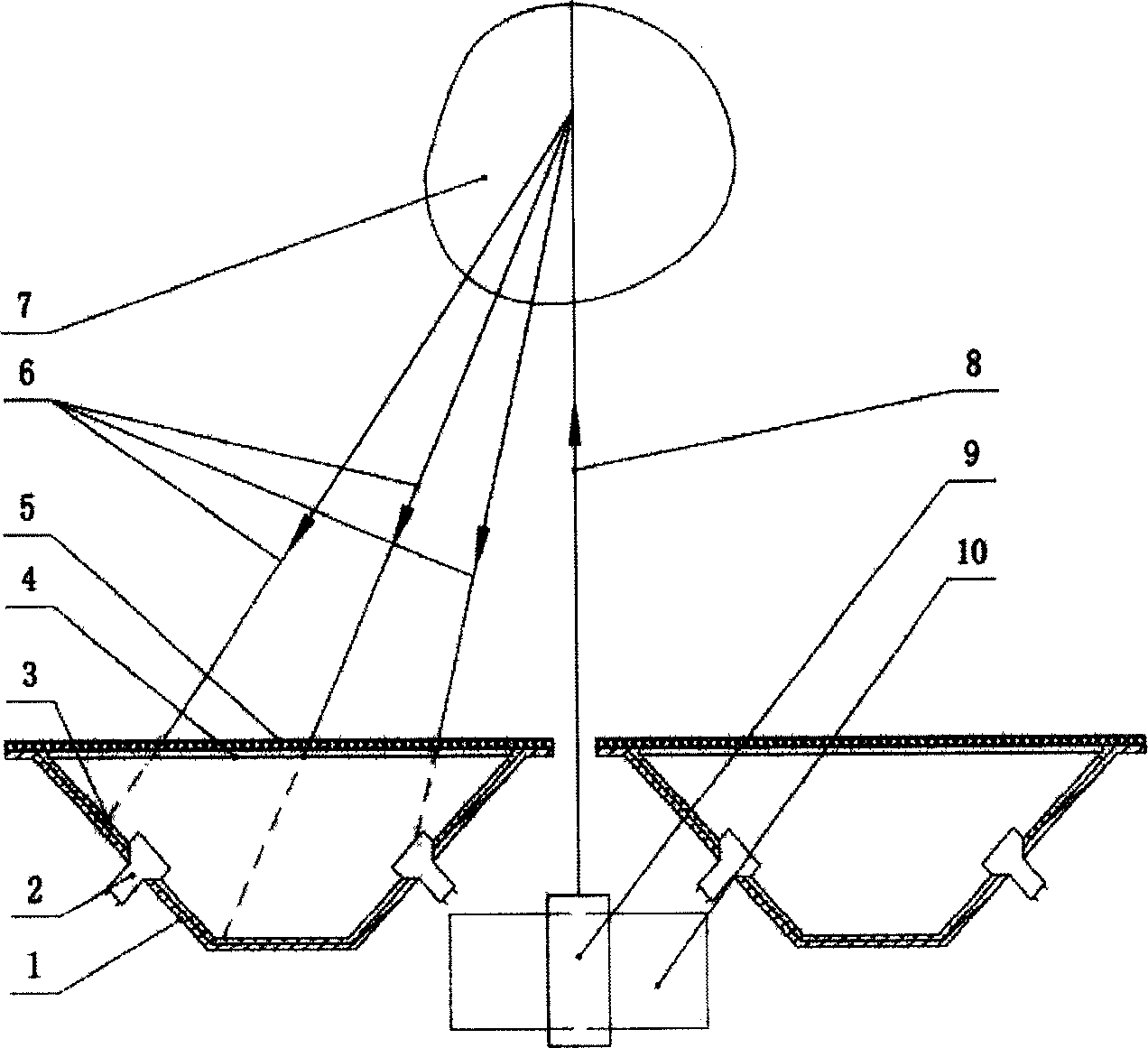

[0012] Now in conjunction with the accompanying drawings, the structure and working principle of the present invention will be further described:

[0013] The invention is suitable for high kilovolt (300KeV-10MeV) X-ray point scanning imaging system.

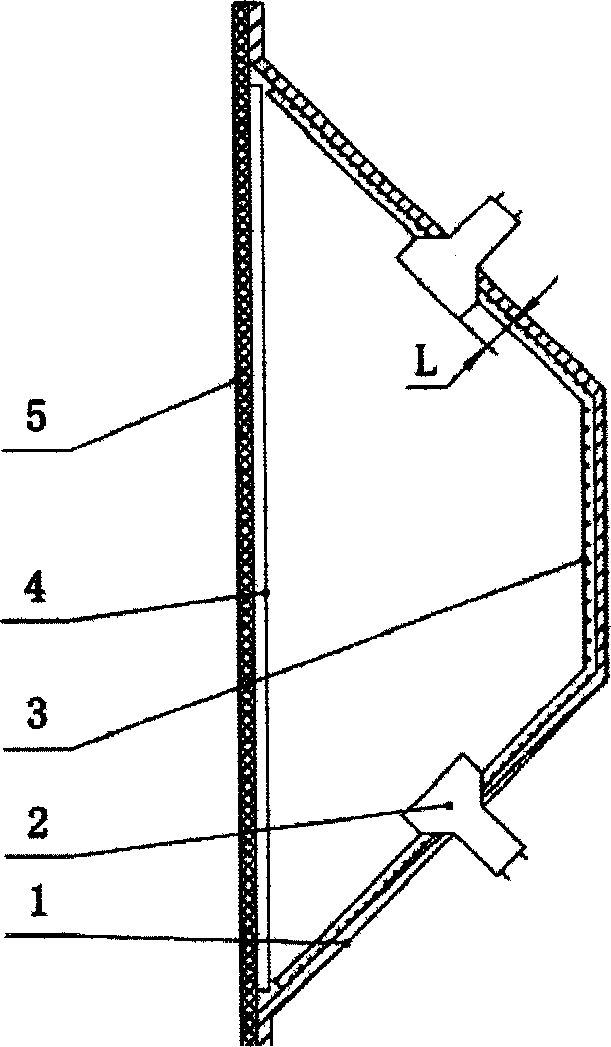

[0014] as attached figure 1 As shown, the present invention adopts a truncated quadrangular pyramid structure, and a sealed shell is formed by the bottom surface of the cone, the top surface of the cone and the remaining four cone surfaces. The bottom surface of the cone is an incident window for X-rays, the outer layer is an aluminum-plastic plate 5, and the inner layer is a barium fluoride chloride screen 4. The aluminum-plastic plate 5 is composed of a polyethylene plate with a thickness of 2 to 5 mm and a thickness of 0.02 to 5 mm. Aluminum foil with a thickness of 0.04 mm; the aluminum-plastic plate 5 has high X-ray permeability, which not only seals light but also supports the barium fluoride chloride screen 4, and the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com