Method for producing a buried tunnel junction in a surface-emitting semiconductor laser

A surface emission and semiconductor technology, applied in the direction of semiconductor lasers, optical waveguide semiconductor structures, lasers, etc., to achieve high output, high single-mode performance, and stable horizontal single-mode operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

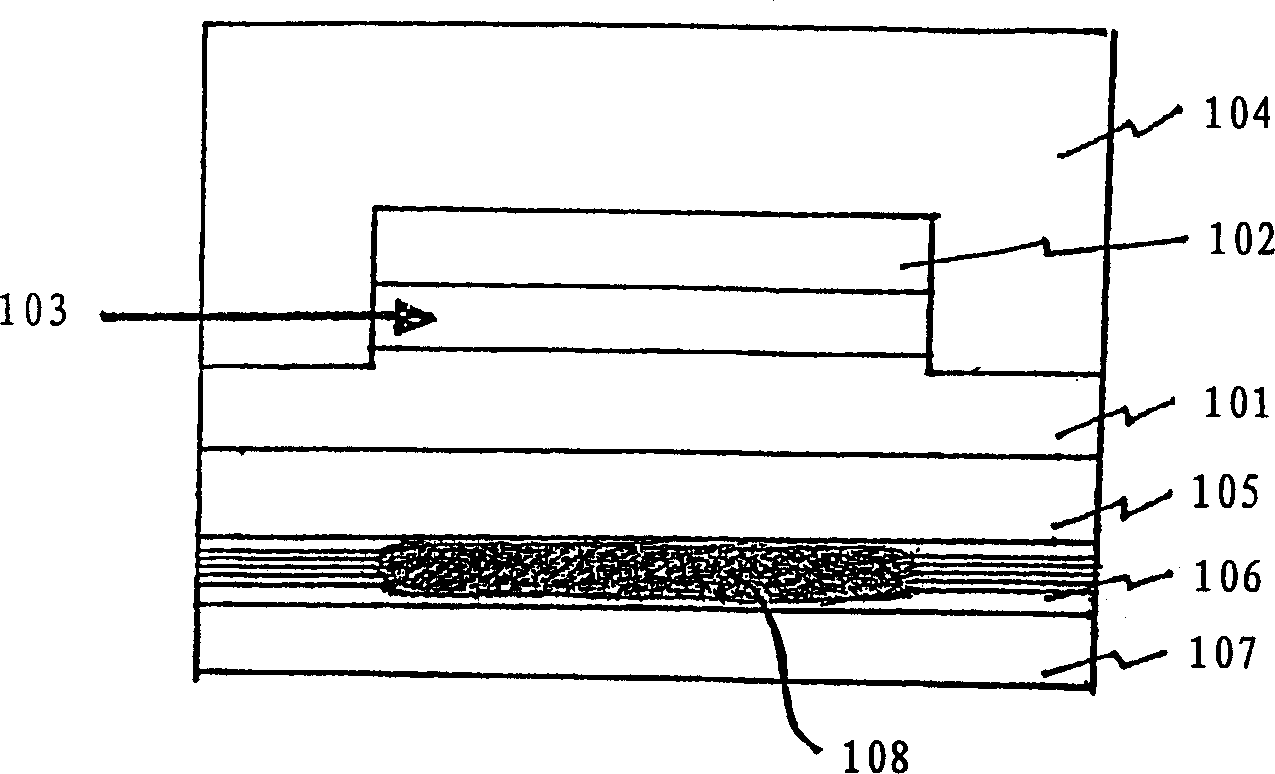

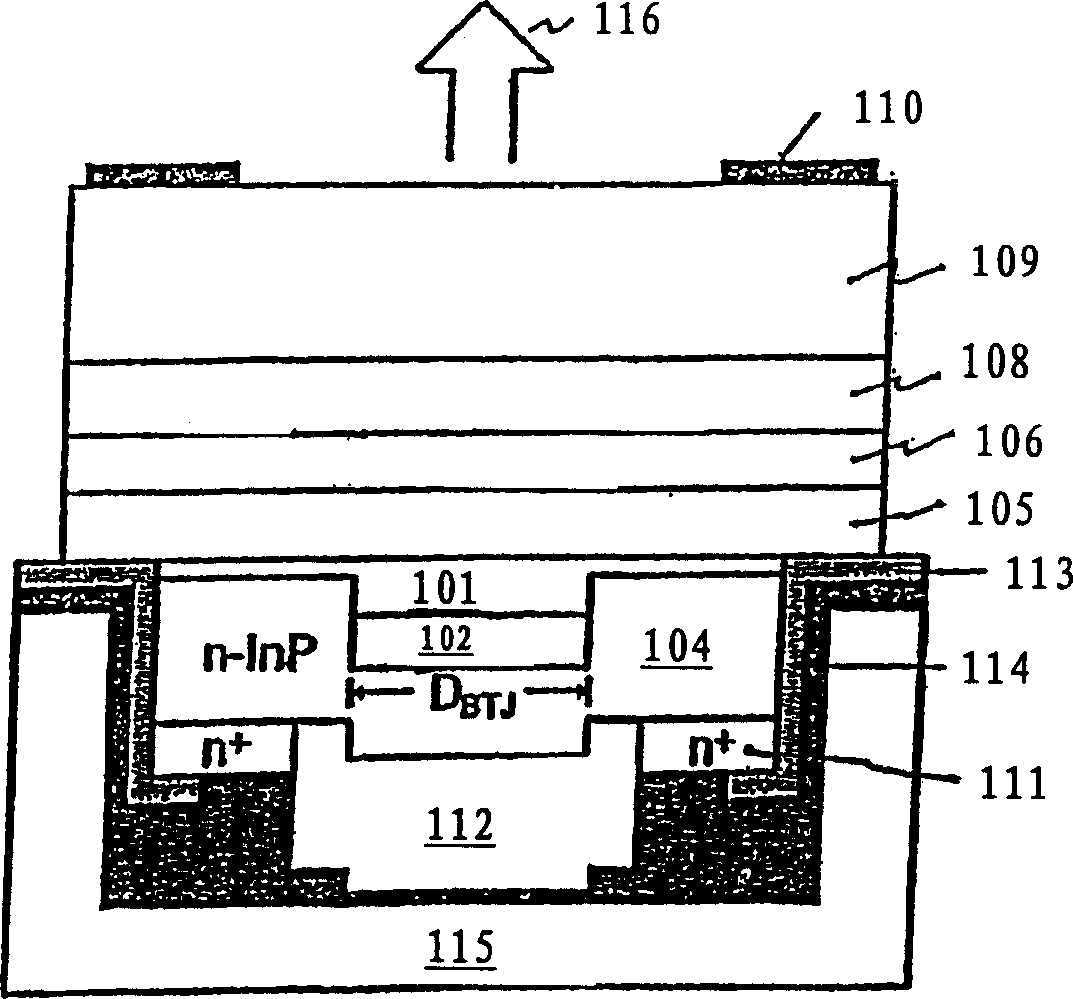

[0039] At the beginning of the manual, it is introduced according to the figure 1 Or 2's buried tunnel junction and the fabrication and structure of a surface-emitting laser diode with such a tunnel junction. Below, will refer to Figures 3 to 10 Embodiments of the present invention will be described in more detail.

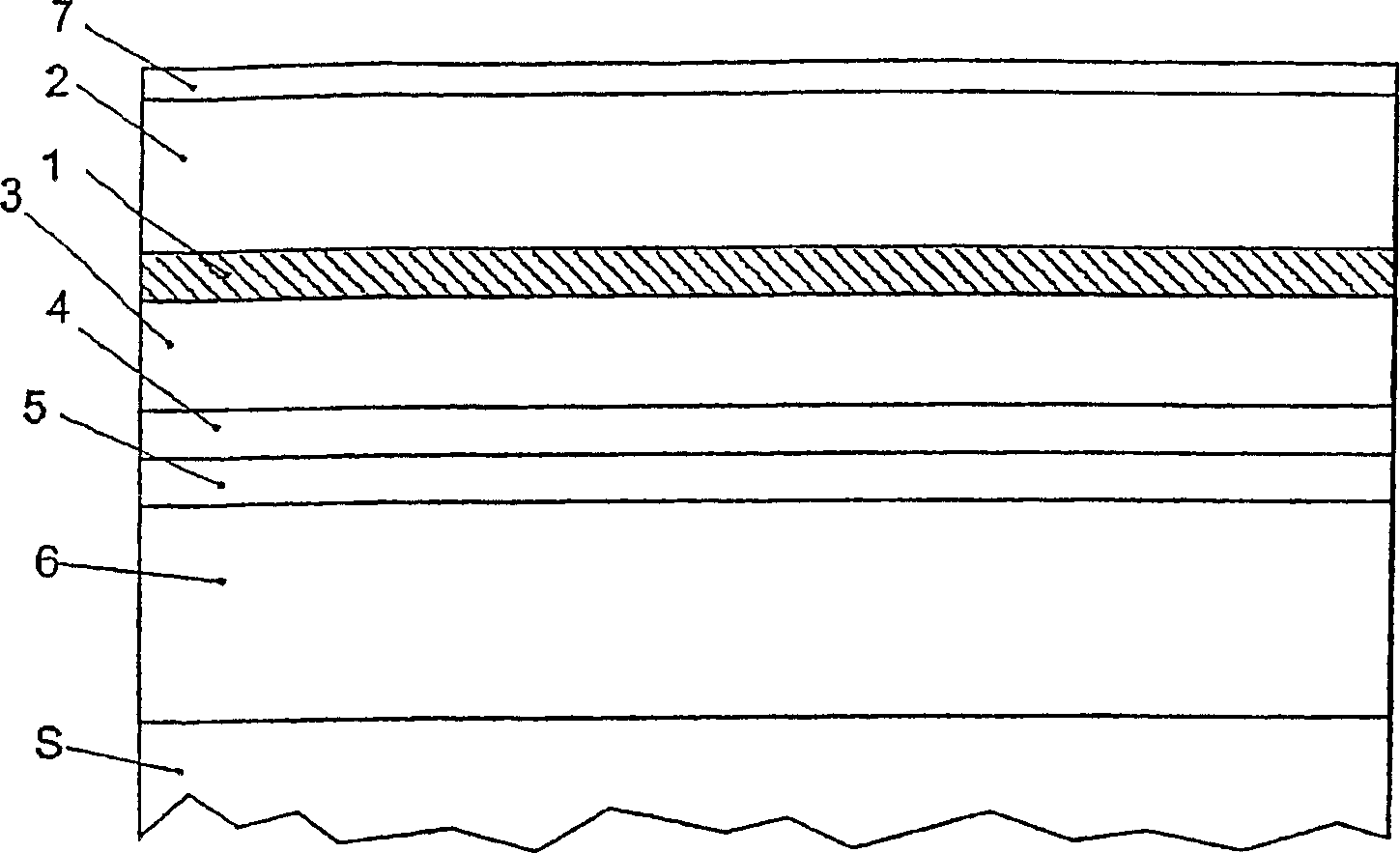

[0040] image 3 A general epitaxial initial structure for an MT-VCSEL according to the invention is schematically shown. Starting with an InP substrate S, sequentially deposit an n-doped epitaxial Bragg mirror 6, an active region 5, an optional p-doped InAlAs layer 4, a p-doped bottom InP layer 3, a wave junction in a longitudinal electric field (minimum) A tunnel junction 1 comprising at least one layer of each of highly p- and n-doped semiconductor layers, an n-doped upper InP layer 2, and n + The upper contact layer 7 is doped.

[0041] Next, through photolithography and etching, in accordance with the image 3 Circular or elliptical bumps (stamps) are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com