Method of manufacturing electrolytic metal manganese using titanium white waste acid and manganese dioxide ore

A technology of manganese dioxide ore and electrolytic metal manganese, which is applied in the field of metallurgical chemistry, can solve problems such as environmental pollution, and achieve significant economic benefits and good filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

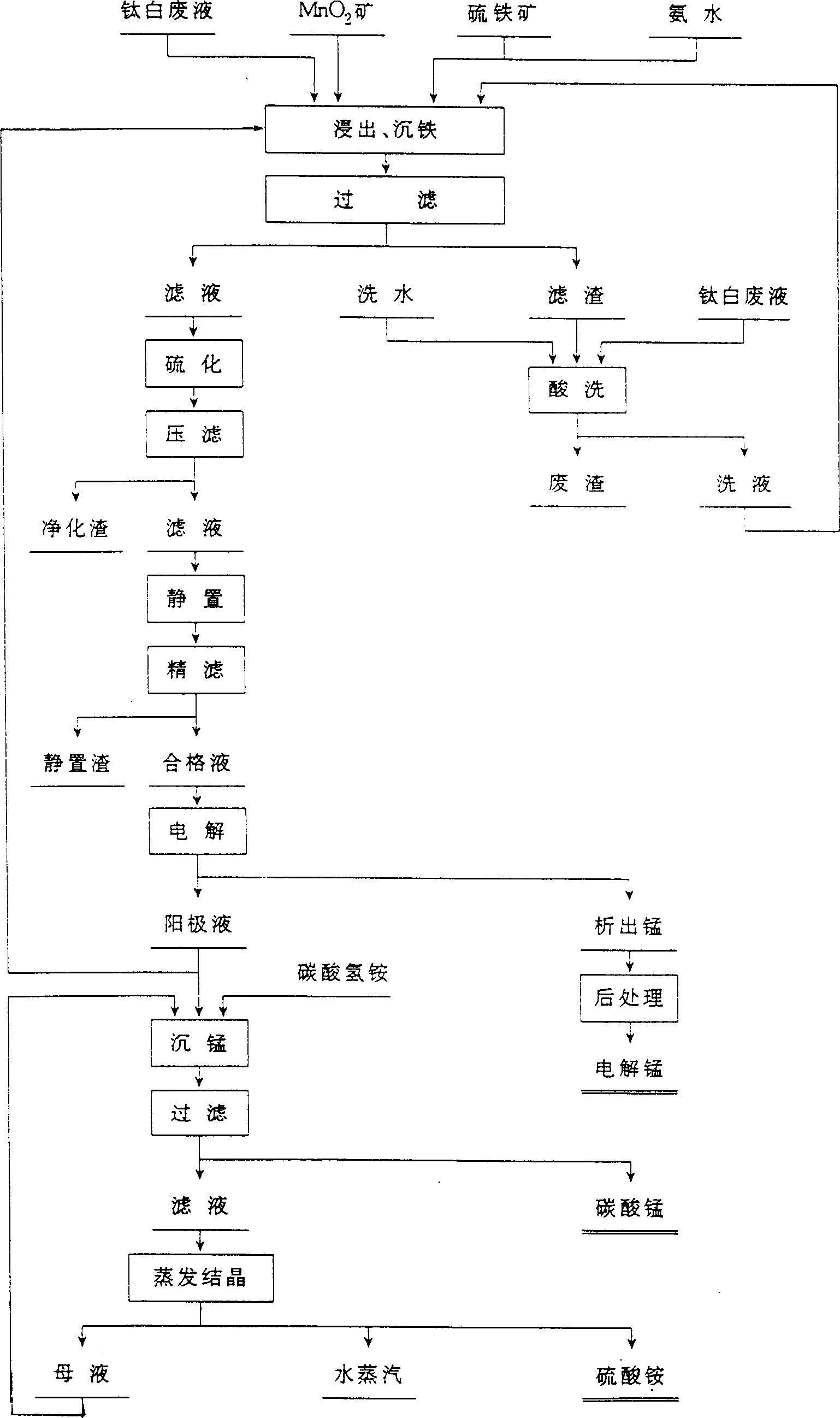

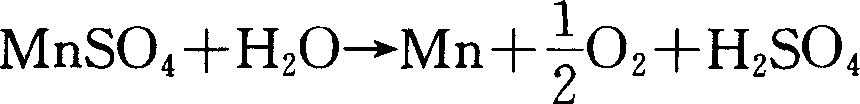

[0040] figure 1 The process flow of producing electrolytic manganese metal from titanium white waste acid is described, and the H in titanium white waste acid is used 2 SO 4 with Fe 2+ As auxiliary materials, manganese dioxide ore and pyrite are added to produce electrolytic manganese metal:

[0041] 1. Leaching and iron removal

[0042] The leaching is carried out in a circular mechanical stirring tank of 6m×5.0m, and the initial acid concentration of leaching is 55.6kg / m 3 , The leaching temperature is 90℃~95℃, the leaching time is 2.5h, and the oxidation precipitation time is 1~2h. The removal rate of Fe is above 99%, and the leaching rate of Mn is more than 95%. The leaching and filtering performance of Fe is good.

[0043] The amount of waste acid used for leaching titanium dioxide is 77.90m 3 / d, and add manganese electrolytic anolyte 460m 3 / d, slag washing water 206m 3 / d;

[0044] According to the experimental research results, every 1m invested 3 Add 860kg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com