Sponge with gas phase rust-proof layer and pressure-sensitive adhesive for multiple metal and its production method

A technology of gas-phase anti-rust and gas-phase anti-rust agent, which is applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of oil layers that are difficult to handle, pollute, and difficult to wrap, and achieve low manufacturing costs and simple production processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

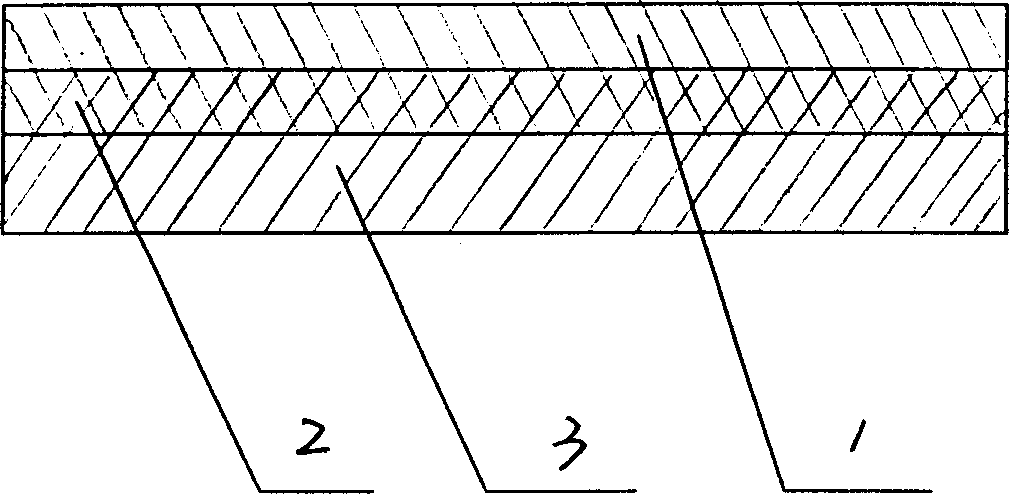

[0034] Such as figure 1 As shown, the above-mentioned multi-metal vapor phase anti-rust pressure-sensitive adhesive sponge comprises an upper layer 1, a middle layer 2, and a lower layer 3, the middle layer 2 is a sponge layer, the upper layer 1 is a gas-phase anti-rust hot-melt pressure-sensitive adhesive layer, and the lower layer 3 is a gas phase Anti-rust layer.

[0035] The above-mentioned sponge layer is polyethylene sponge, the foaming rate is 20-30 times, the thickness is 0.5-100mm, and different colors can be selected.

[0036] The above-mentioned hot-melt pressure-sensitive adhesive layer is prepared from the following components by weight ratio:

[0037] Styrene, butadiene or isoprene block copolymer 0.30-0.40

[0038] White oil or naphthenic oil 0.20-0.30

[0039] Lightened rosin or terpene resin 0.10-0.20

[0040] Antioxidant 0.005-0.01

[0041] Cyclohexylamine Benzoate 0.08-0.20

[0042] Ammonium benzoate 0.06-0.15

[0043] Benzotriazole 0.03-0.08

[0044...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com