Manufacturing process of MEMS impression template based on wet etching

A wet etching and manufacturing process technology, which is applied in the photoengraving process of pattern surface, photoengraving process coating equipment, semiconductor/solid-state device manufacturing, etc., can solve the problem of short etching resistance time and long metal layer deposition time. , etching and other problems, to improve the quality of the etched surface, eliminate surface defects, and reduce the undercut rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

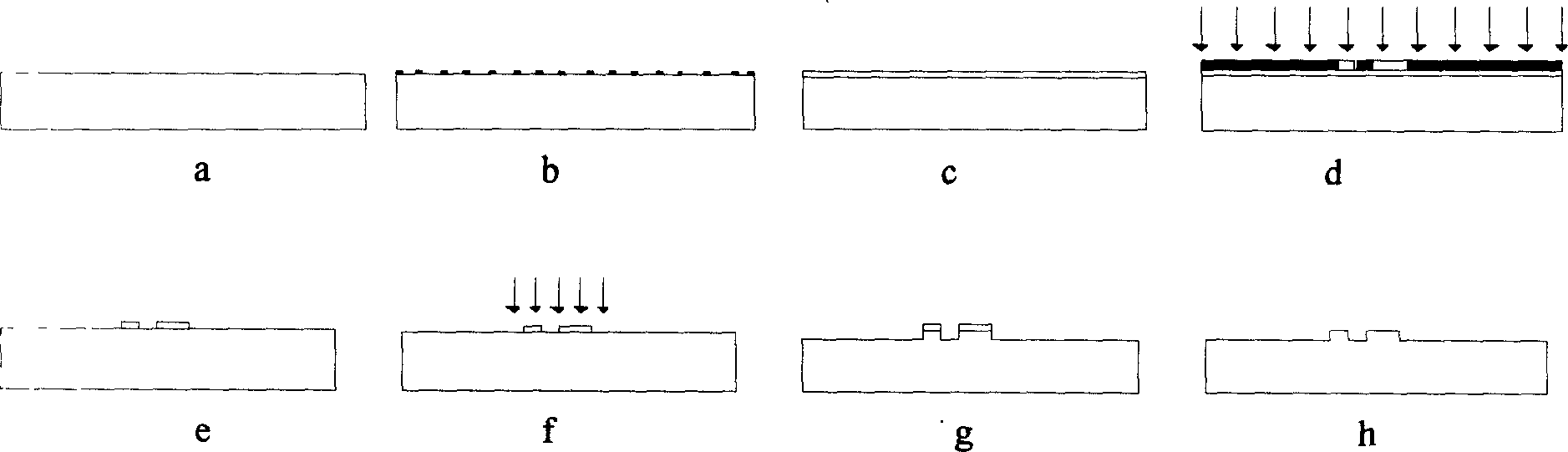

[0023] figure 1 For overall process flow diagram of the present invention, comprise the following steps:

[0024] Glass cleaning process ( figure 1 a) is: first wipe the glass with acetone, then rinse it with distilled water, soak the rinsed glass in concentrated sulfuric acid for 10 minutes; take it out, rinse it with distilled water, and dry it at 100°C for 10 minutes to remove the dirt on the glass ; Thorough cleaning can greatly reduce the etching defects caused by glass surface contamination.

[0025] After cleaning, adopt the mode of vapor deposition to carry out the spreading of silane coupling agent ( figure 1 b) The type of coupling agent used is KH-570. The coupling agent is used to improve the bonding force between photoresist and glass. The process of evaporating the coupling agent is: the temperature is 80°C, and the evaporation time is 30min , post-treatment after evaporation, the post-treatment method is to bake at 120 ° C for 40 minutes.

[0026] Next, glue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com