Precise laser engraving forming technology for coronary artery stent

A laser and coronary technology, applied in the field of laser applications, can solve problems such as difficulty in chip falling and inability to fully meet processing accuracy requirements, and achieve the effects of reducing process difficulty, preventing local overheating and mechanical stress release, and improving quality and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

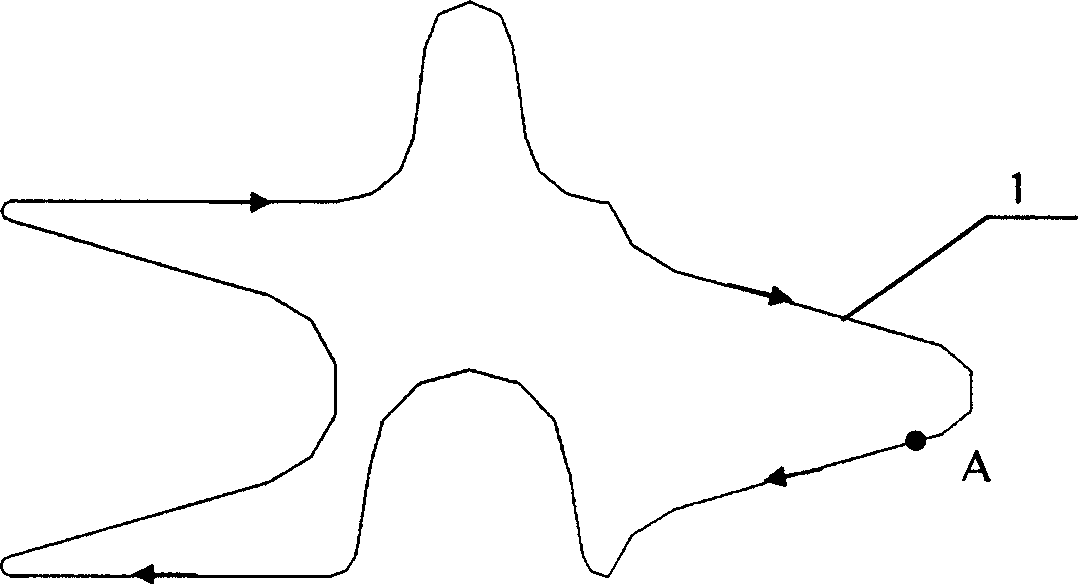

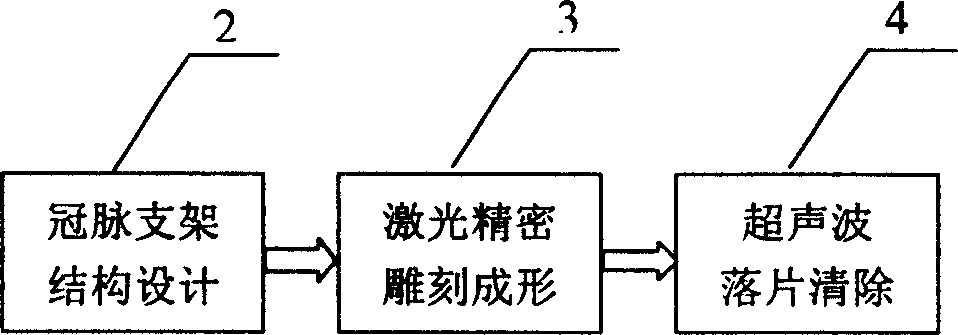

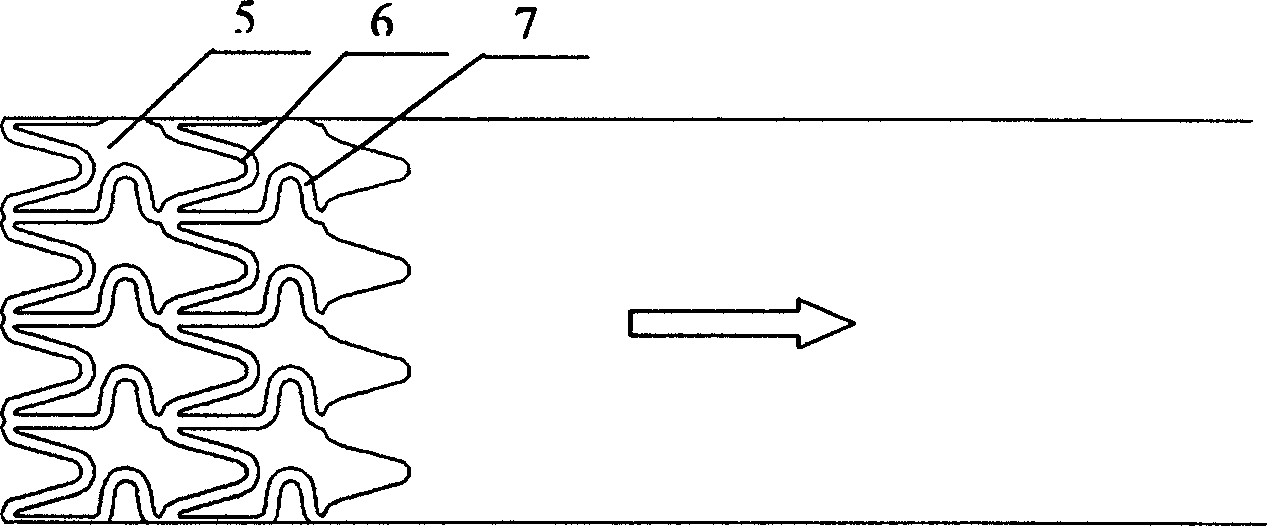

[0010] The process method of the coronary stent laser precision engraving and forming of the present invention, according to figure 2 The process flow shown is carried out according to image 3 The coronary stent structure shown is designed with a closed-cell sculpted path, according to Figure 5 Divide the cell path into three segments as shown, as indicated by 13, 14, 15, by Image 6 As shown, the unit engraving path controls the program flow for engraving. Engraving is achieved through the relative movement of the focused laser beam on the surface of the stainless steel pipe. When working, the laser beam is perpendicular to the surface of the pipe and remains in a static state. The pipe is controlled by the numerical control system through mechanical components according to the pre-designed graphics. Rotate and feed, synthesize movement track to carry out engraving, engraving process according to Figure 4 To execute the engraving process shown, the laser parameters mus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com