Diisodecyl phthalate preparation method

A technology of diisodecyl phthalate and phthalic anhydride, which is applied in the field of plasticizer preparation, can solve complex process, low product yield, volatility, extraction resistance and migration resistance, heat aging resistance Insufficient resistance, volume resistivity, water resistance and oil resistance, etc., to achieve the effect of simplifying the process, high volume resistivity, and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Esterification reaction

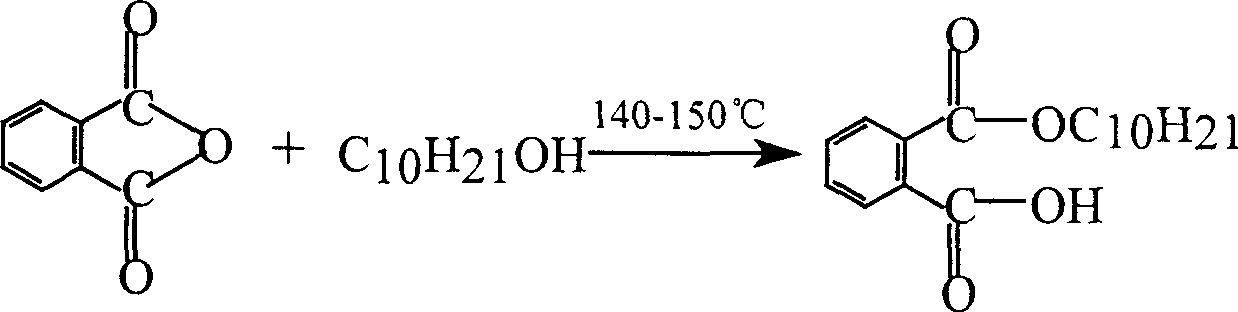

[0029] ①Monoesterification reaction: Add 143.5g of phthalic anhydride and 383g of isodecyl alcohol into a reaction kettle equipped with a stirrer, thermometer, water separator, condenser pipe and nitrogen gas inlet pipe, and at the same time, nitrogen gas is introduced, and the stirring is turned on The device starts to heat up, and when the reaction temperature reaches 140-150° C., it is kept for 10 minutes to end the monoesterification reaction.

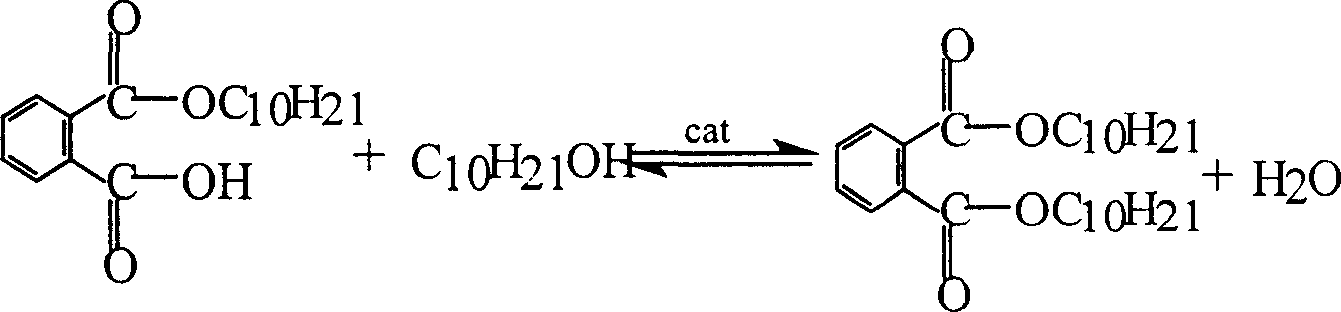

[0030] ②Diesterification reaction: After phthalic anhydride is completely converted into monodecyl phthalate acid, continue to stir and heat up to 180°C, add 100 μL catalyst isopropyl titanate, and continue to stir and heat up to 210°C. Carry out constant temperature double esterification reaction 4 hours, after double esterification reaction finishes, product is cooled to room temperature, takes a sample and measures product acid value with acid-base titration (following analysis method is the ...

Embodiment 2

[0037] (1) Esterification reaction

[0038] ①Monoesterification reaction: Add 71.70g of phthalic anhydride and 197.4g of isodecyl alcohol into a reaction kettle equipped with a stirrer, thermometer, water separator, condenser tube and nitrogen inlet tube, and at the same time, nitrogen gas is introduced, and the Stirrer, start to heat up, when the reaction temperature reaches 140 ~ 150 ℃, keep for 10 minutes to end the monoesterification reaction.

[0039] ②Diesterification reaction: After the monoesterification reaction, raise the temperature to 180°C, add 50 μL catalyst isopropyl titanate, continue to raise the temperature to 220°C, carry out the double esterification reaction at constant temperature for 3 hours, and then end the diesterification reaction. Sampling analysis.

[0040] (2) post-processing

[0041] The process of dealcoholization under reduced pressure, alkali washing, water washing, steam stripping, cooling, and filtration, the operation process and conditio...

Embodiment 3

[0044] (1) Esterification reaction

[0045] ①Monoesterification reaction: Weigh 71.70g of phthalic anhydride and 191.5g of isodecyl alcohol into a reaction kettle equipped with a stirrer, thermometer, water separator, condenser pipe and nitrogen inlet pipe, and feed nitrogen at the same time. Turn on the stirrer and start to heat up. When the reaction temperature reaches 140-150°C, keep it for 10 minutes to end the monoesterification reaction

[0046] ② Diesterification reaction: After the monoesterification reaction, continue to heat up to 180°C, add 50 μL of catalyst isopropyl titanate, then continue to heat up to 190°C, carry out constant temperature double esterification reaction for 4.5 hours, and then end the monoester reaction. Sampling analysis.

[0047] (2) post-processing

[0048] The process of dealcoholization under reduced pressure, alkali washing, water washing, steam stripping, cooling, and filtration, the operation process and conditions are the same as in Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com