Method for coke benzene oxydation to produce maleic anhydride

A technology for coking benzene and maleic anhydride, applied in the direction of organic chemistry, etc., can solve the problems of incapable production, processing, large investment and high technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

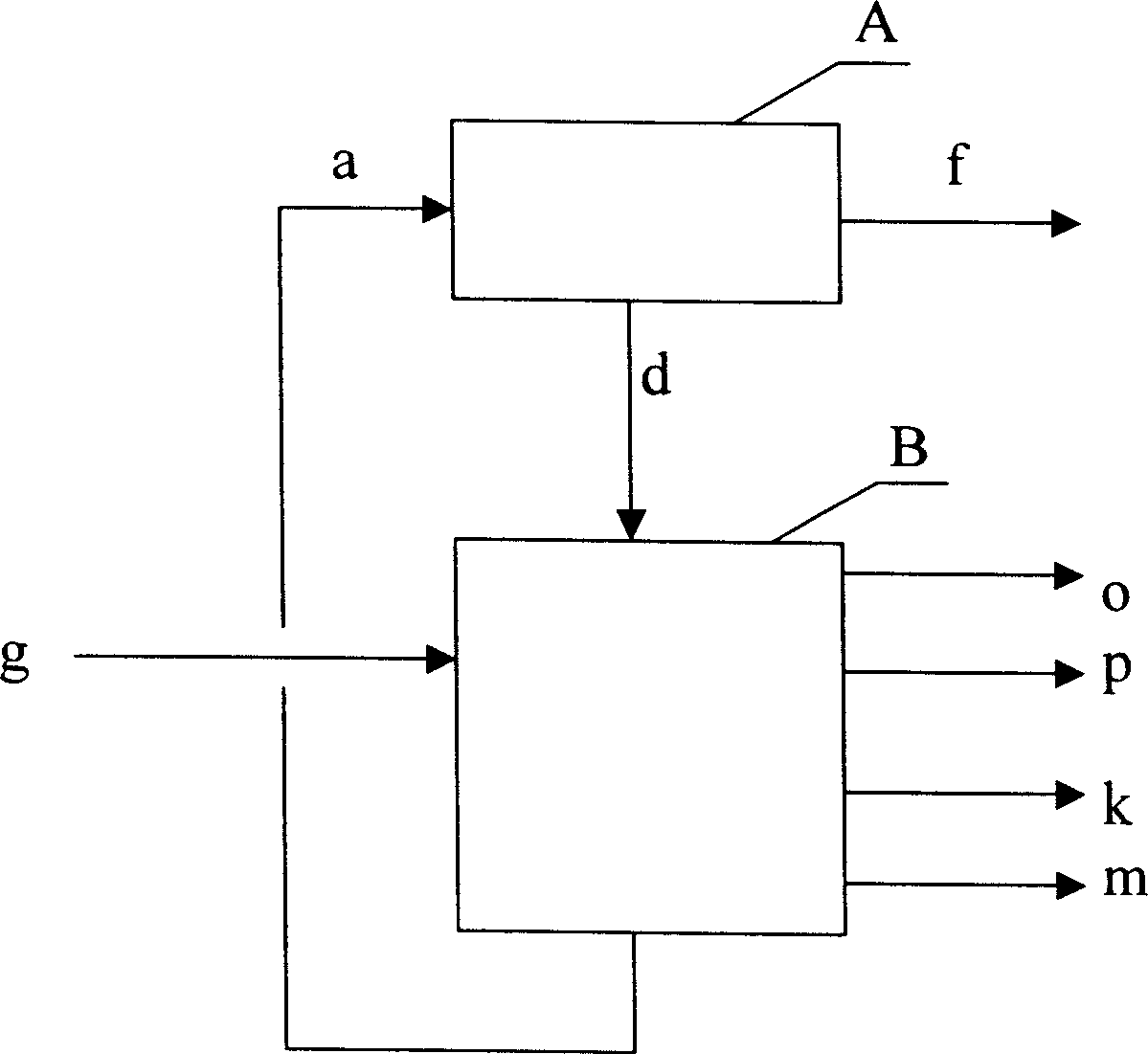

[0113] The combined process of crude benzene refining pickling process and benzene oxidation to maleic anhydride process is as described in the following examples, see figure 1: crude benzene g, 57,000 tons / year, enter crude benzene refining pickling process B, process and refine, get product coking benzene a, 37,500 tons / year, coking toluene o, 7150 tons / year by-product simultaneously, coking two Toluene p, 2120 tons / year, acid slag k, 4240 tons / year, alkali slag m, 5300 tons / year; coking benzene a produced by B is used as raw material for benzene oxidation to maleic anhydride process A, and the product is obtained through catalytic oxidation reaction Maleic anhydride f, 30,000 tons / year, at the same time by-product 2.5Mpa high-pressure steam d, 135,000 tons / year, sent to crude benzene refining pickling process B, as the heat source of each distillation tower in the refining process. Therefore, the combination of these two processes realizes the complementarity, mutual benefi...

Embodiment 2

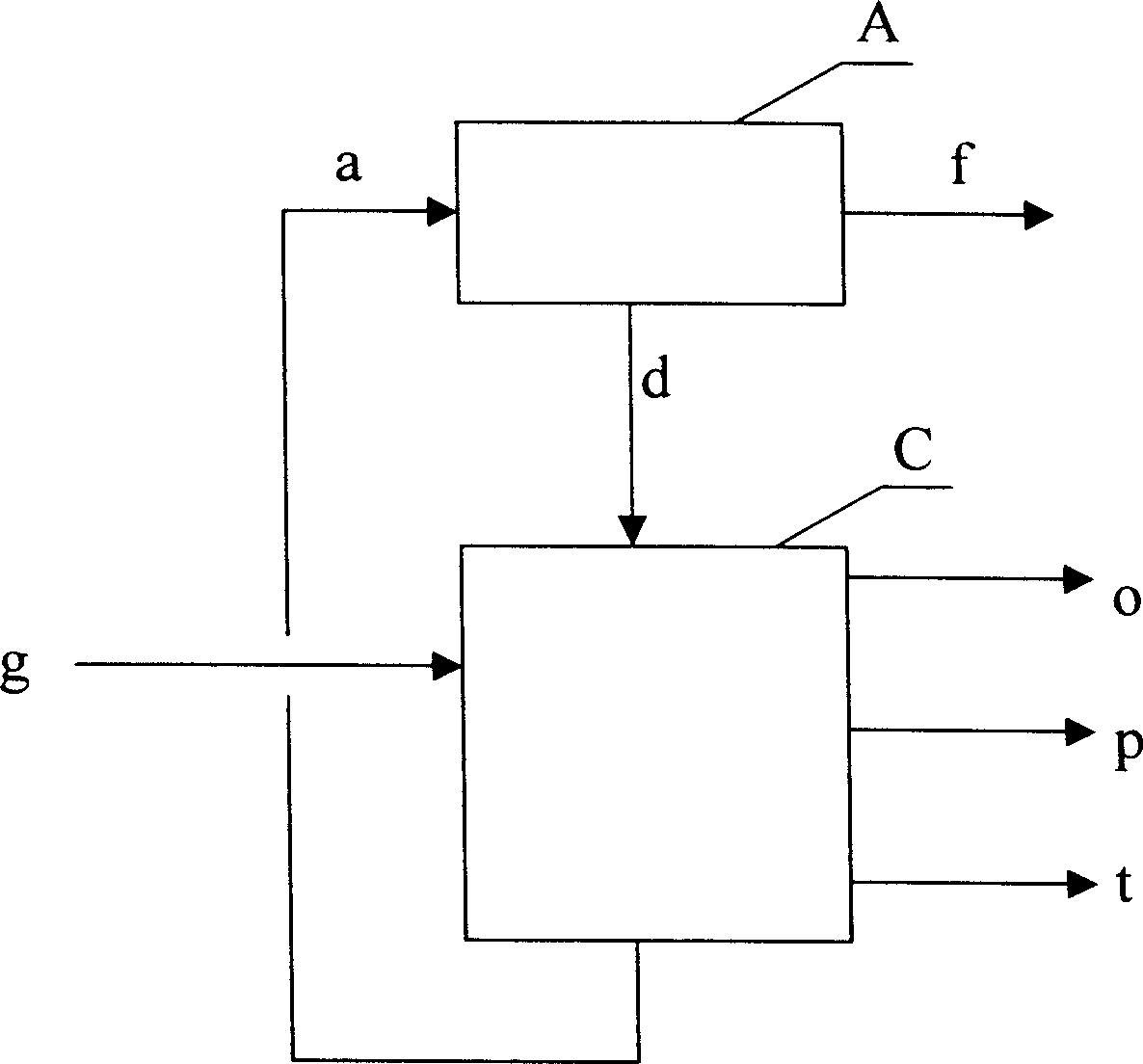

[0127] The combined process of crude benzene refining extractive distillation process and benzene oxidation to maleic anhydride process is as described in the following examples, see figure 2 : Crude benzene g, 18.5 tons / year, enters crude benzene refining extraction and rectification process C, after processing and refining, the product coking benzene a is obtained, 125,000 tons / year, and the by-product coking toluene o, 28,200 tons / year, coking Xylene p, 8325 tons / year, and high value-added thiophene t, 1000 tons / year, no acid residue and alkali residue discharge; coking benzene a produced by C is used as the raw material of benzene oxidation to maleic anhydride process A, through catalytic oxidation The reaction produces maleic anhydride f, 100,000 tons / year, and the by-product 2.5Mpa high-pressure steam d, 448,000 tons / year, is sent to crude benzene refining extractive distillation process C as a heat source for each distillation tower in the refining process. Therefore, ...

Embodiment 3

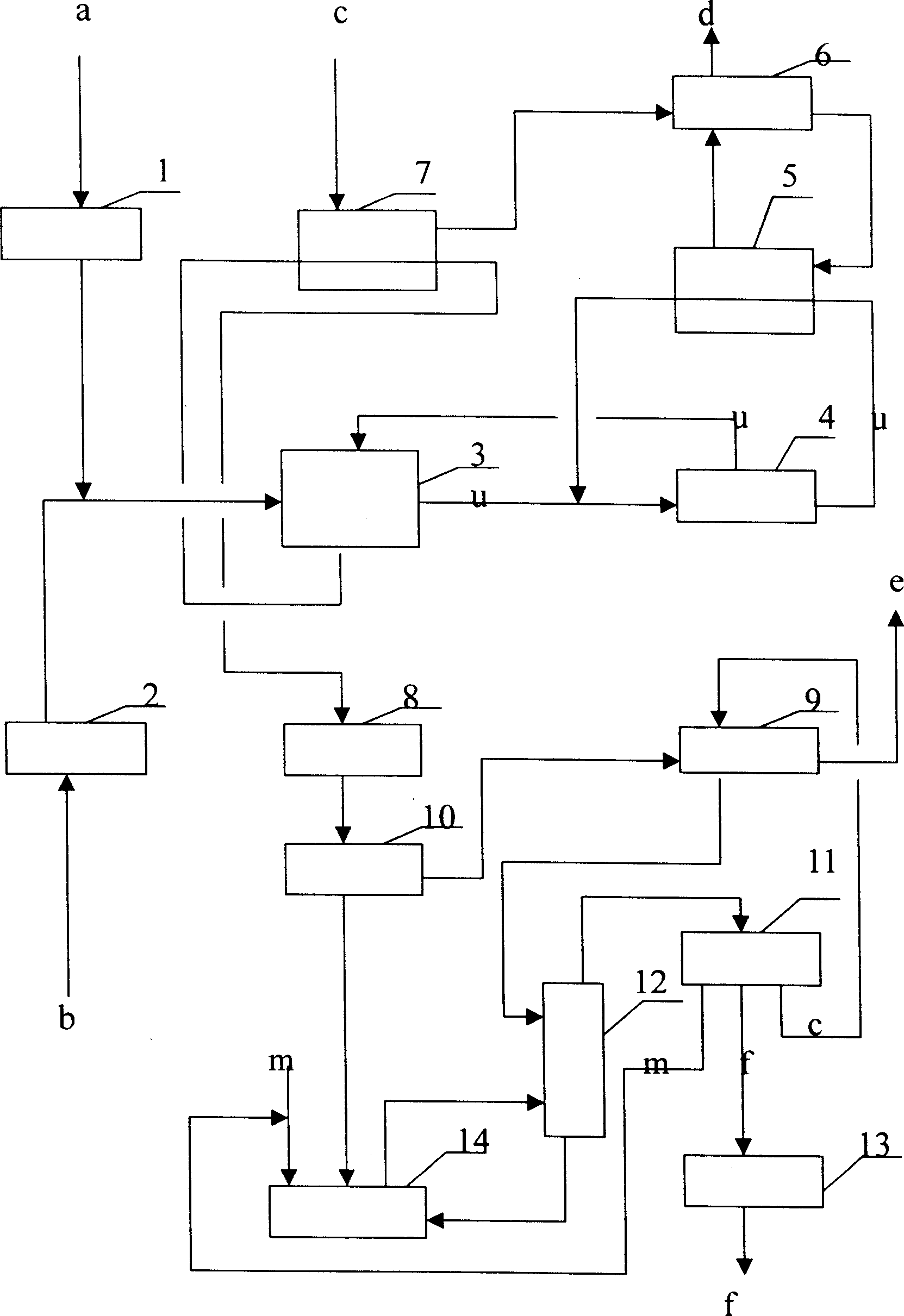

[0135] The combined process of crude benzene refining extractive distillation process and benzene oxidation to maleic anhydride process, N-methylpyrrolidone is used as the extraction agent, and the solvent ratio is 6:1. The benzene extraction tower 25 operates under normal pressure, and the operating temperature at the top of the tower is 73°C; the tower 20 operates under normal pressure, and the operating temperature at the top of the tower is 80°C; the tower 26 operates under normal pressure, and the operating temperature at the top of the tower is 81°C; The operating pressure of the extraction tower 27 is normal pressure, and the operating temperature at the top of the tower is 80°C; the operating pressure of the thiophene refining tower 28 is normal pressure, and the operating temperature at the top of the tower is 84°C; the tower 22 is operated at normal pressure, and the temperature at the top of the tower is 140°C . After the above process, the obtained coked benzene ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com