Method for preparing composite amino acid liquid using waste protein

A technology for compound amino acid and waste protein, applied in the field of preparing compound amino acid liquid, can solve the problems of damage, increase production cost, long hydrolysis time, etc., and achieve the effects of high hydrolysis efficiency, low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

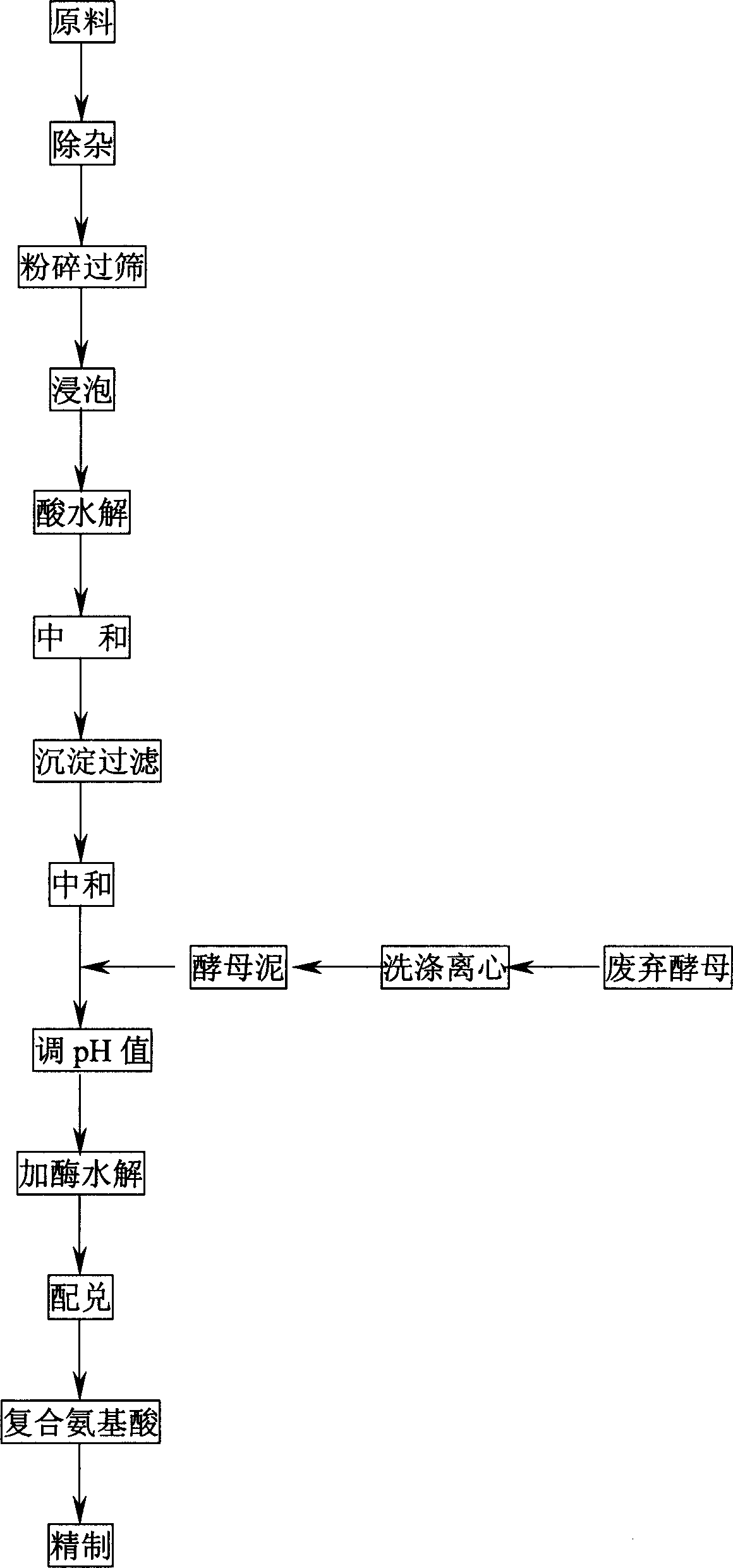

Image

Examples

Embodiment 1

[0013] a. Raw material pretreatment: First, after removing impurities, crushing soybean meal, rapeseed cake and cottonseed cake, sieving (20-100 mesh), soaking with 200% (weight percent) dilute sulfuric acid for 12 hours, and filtering off the supernatant liquid, steamed for 1 hour. The waste yeast is washed and centrifuged to collect the yeast sludge and refrigerate for future use.

[0014] b. Mixing: Mix the above-mentioned processed vegetable protein materials uniformly in a ratio of 1:1:0.3 (weight ratio), and control the moisture content of the mixture within 50%. Then the mixture is mixed with the treated yeast mud at a ratio of 1:0.5 (weight ratio).

[0015] c. Enzyme hydrolysis: add 5-8 times of water to it, add neutral protease according to the addition amount of 2000u / g raw materials, and perform constant temperature enzymolysis under the condition of 45-52°C for 4-6 hours.

[0016] d. Acid hydrolysis: Add food-grade pure hydrochloric acid to the above mixed soluti...

Embodiment 2

[0020] Embodiment 2: repeat embodiment 1, have following difference: in the raw material pretreatment step, soak 20 hours with the dilute sulfuric acid of 200% (percentage by weight), boil 30 minutes. The results showed that the yield of amino acid was 11.2%, and the taste was slightly worse than that of Example 1.

Embodiment 3

[0021] Embodiment 3: repeat embodiment 1, have following difference: in the raw material pretreatment step, soak 20 hours with the dilute sulfuric acid of 200% (percentage by weight), cook for 2 hours. The results showed that the yield of amino acid was 11.7%, and the taste was slightly worse than that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com