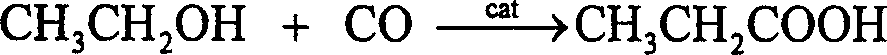

Process for synthesizing methyl acetic acid catalyst by ethanol carbonylation

A technology of chemical synthesis and catalyst, which is applied in the direction of catalyst activation/preparation, carbon monoxide reaction to prepare carboxylic acid, physical/chemical process catalyst, etc. It can solve the problem of low space-time velocity of ethanol and achieve the effect of improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take by weighing 50 grams of commercial activated carbon (coconut shell), boil in 250ml deionized water for 4 hours, then dry at 120°C for 12 hours, then reflux and boil for 3 hours in a 2% nitric acid solution by weight percentage, then boil at 120°C °C for 12 hours.

[0027] The pretreated activated carbon (AC) is placed in a water bath at 50°C and vacuumized to remove the adsorbed gas and reduce the penetration time of the metal solution. The activated carbon after vacuuming was thrown into the nickel nitrate solution of 3.84% by weight and soaked for 24 hours, then filtered off the excess solution, dried at 80°C for 6 hours, and then dried at 120°C for 6 hours. After taking it out, put it in a water bath at 50°C, put the activated carbon after vacuuming into a 3.84% nickel nitrate solution by weight and soak it for 24 hours, then filter off the excess solution, and dry it at 80°C for 6 hours. It was further dried at 120° C. for 6 hours. In this way, nickel-loaded ...

Embodiment 2

[0030] Except that the nickel nitrate solution of 15% and the copper nitrate solution of 8.6% are selected for use, other conditions and processes are the same as in Example 1, and the catalyst Ni-Cu with a loading of nickel of 10% and a loading of copper of 6% is prepared. / AC. The conversion of ethanol obtained was 90%. The total yield of propionic acid and ethyl propionate was 43%.

Embodiment 3

[0032] Except that the commercial activated carbon was not washed with water, the other preparation process was the same as in Example 1, and a catalyst Ni-Cu / AC with a nickel loading of 5% and a copper loading of 6% was prepared. The conversion of ethanol obtained was 88%. The total yield of propionic acid and ethyl propionate was 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com