Display panel inspection apparatus and display panel inspection method

A technology for a display panel and an inspection device, which is applied in the directions of measuring devices, instruments, and measuring electronics, can solve the problems of a large amount of time required for processing by a data processing unit, affecting the production rhythm of the display panel inspection device, and unfavorable quality management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, a display panel inspection device and an inspection method thereof according to embodiments of the present invention will be described in detail with reference to the drawings.

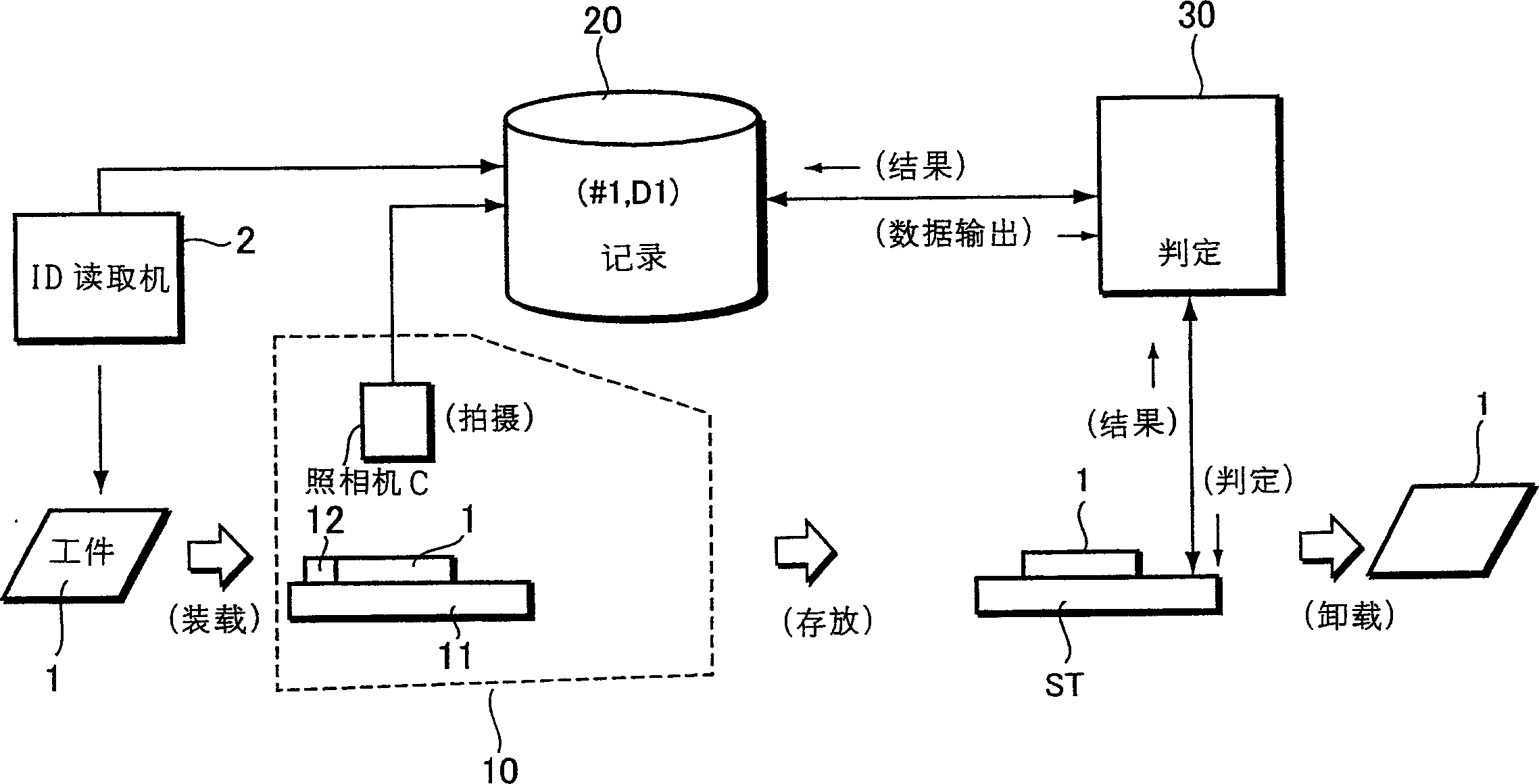

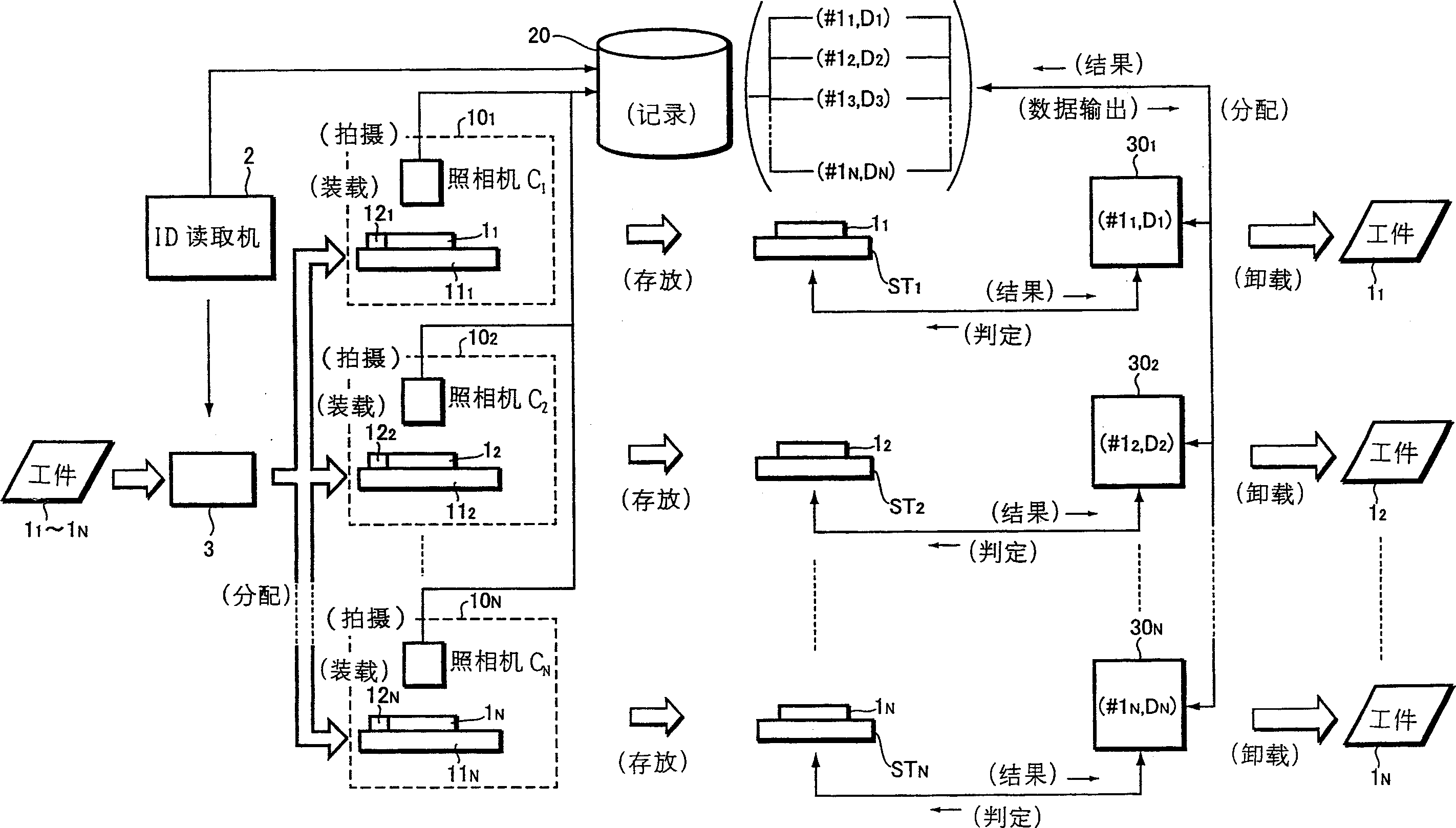

[0020] figure 2 It is a conceptual diagram showing an example of the entire inspection process of a display panel using the display panel inspection device according to the embodiment of the present invention. In the embodiment of the present invention, the display panel (work) to be inspected may be an LCD (Liquid Crystal Display: liquid crystal display panel), PDP (Plasma display Panel: plasma display panel), organic EL (Electroluminescence: organic electroluminescence panel), etc.

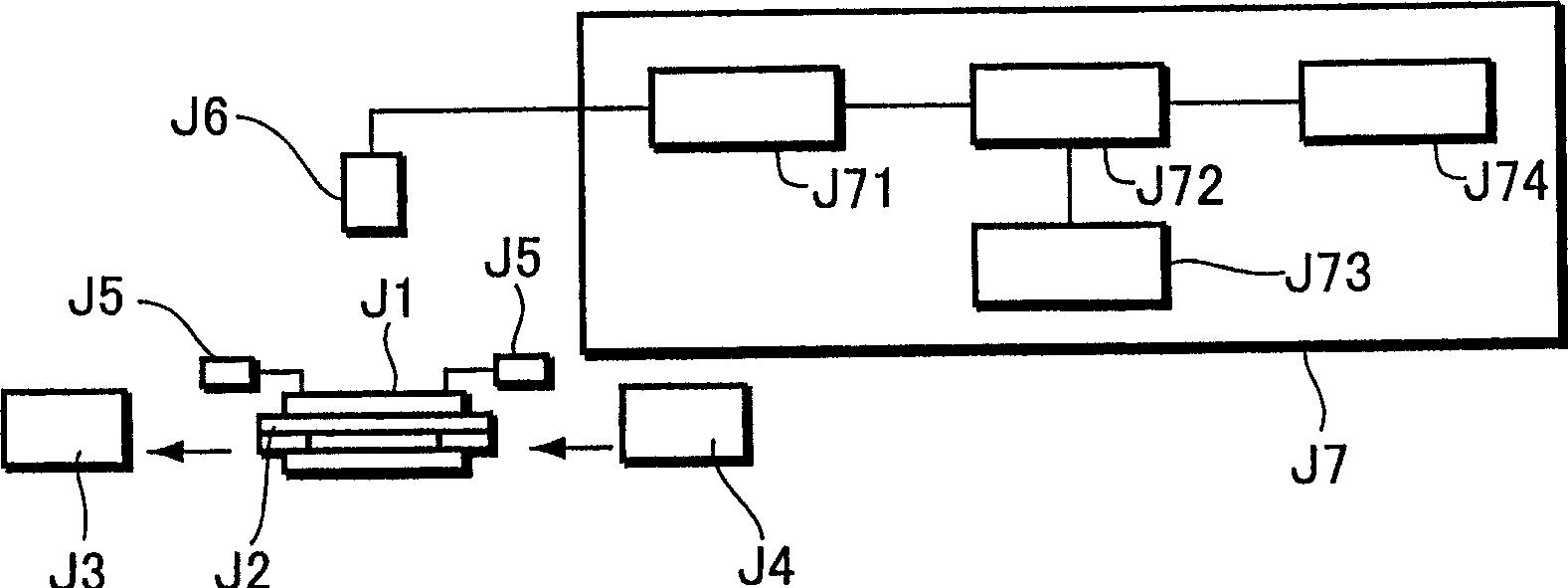

[0021] The display panel inspection device according to the embodiment of the present invention includes: an image detection unit 10 that lights up the display panel according to a detection signal, and obtains image detection data by taking a lighted image; and a data storage unit 20 that uses the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com