P-xylene producing process

A p-xylene and production method technology, applied in the field of petrochemical industry, can solve the problems of large diameter and height of xylene tower, limited output of ortho-xylene, single function of ortho-xylene tower, etc., and achieve reduction of reflux ratio and reduction C8 aromatics circulation amount and the effect of reducing separation precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

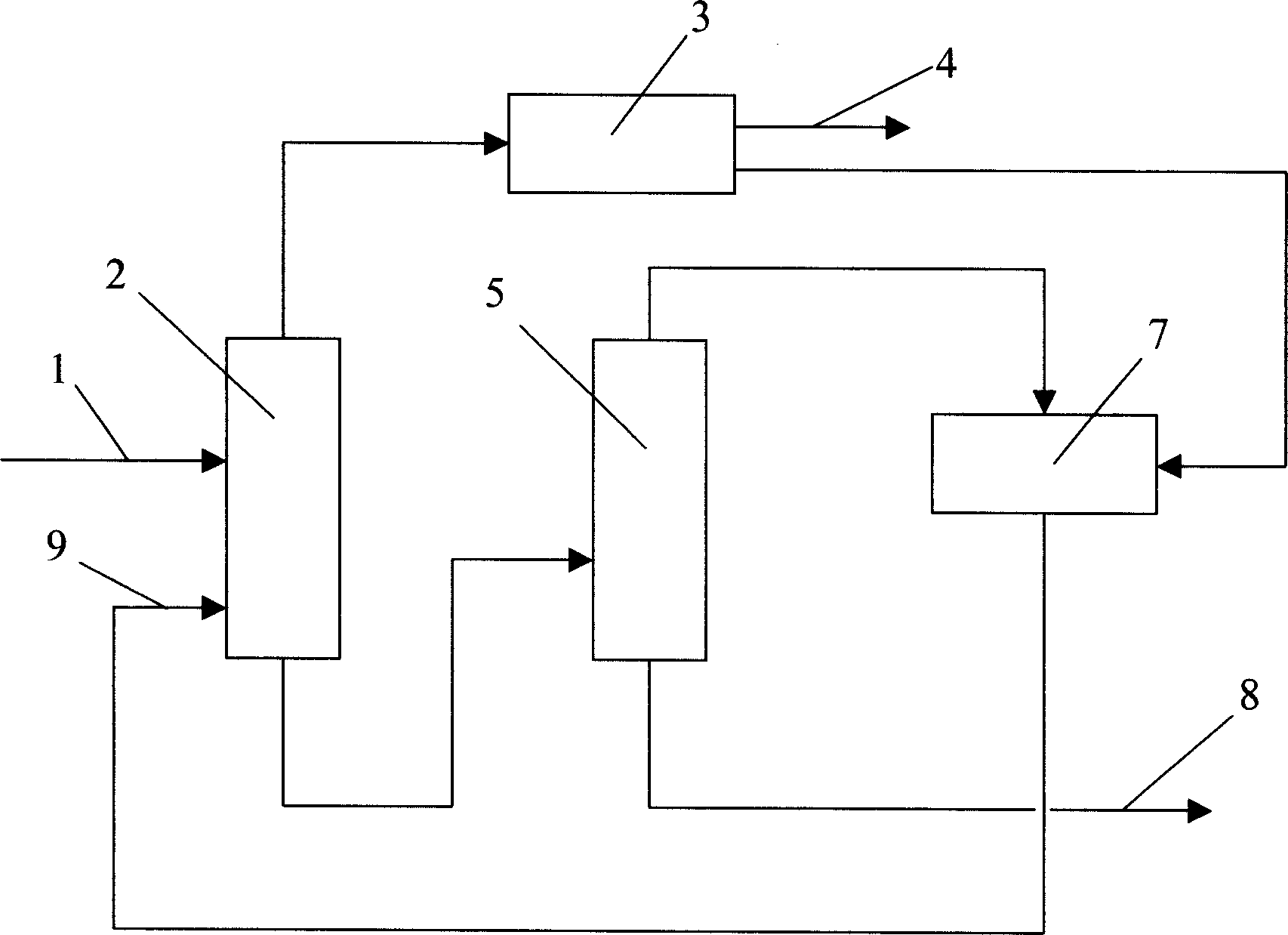

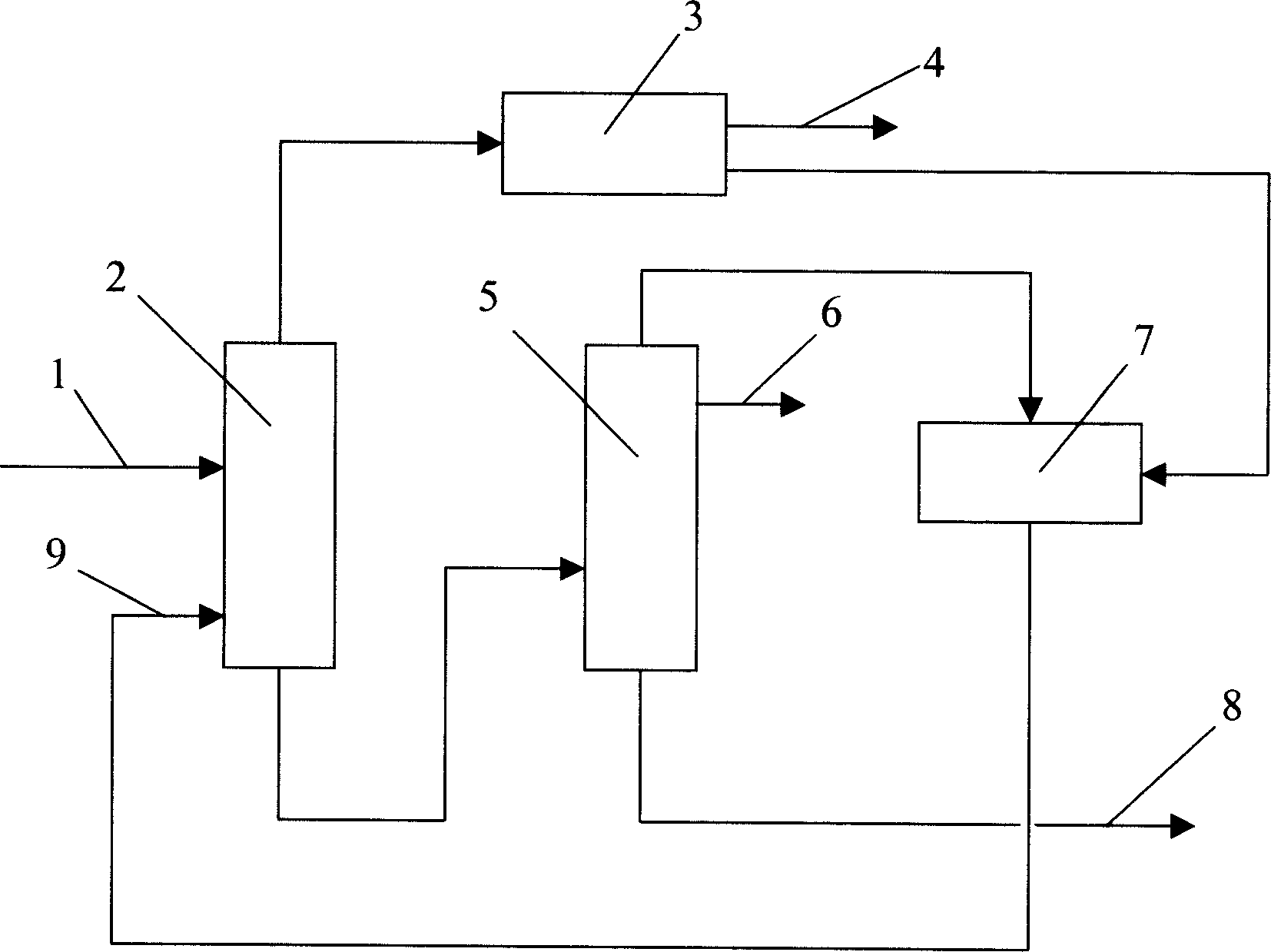

[0013] Such as figure 1 As shown, fresh C 8 + Aromatics Feedstock 1 and Isomerization C 8 + Aromatics 9 enters the xylene tower 2, the tower top pressure of the xylene tower is 0.90MPa (gauge pressure), the tower top temperature is 251°C, the tower bottom temperature is 265~295°C, and the reflux ratio (relative to the tower top product) is 3.6 ~4.2 (weight ratio). From the top of the xylene tower is qualified C 8 Aromatics, to adsorption separation unit 3 to obtain qualified p-xylene product 4 after adsorption separation, adsorption separation unit 3 raffinate to isomerization unit 7, the C containing ortho-xylene at the bottom of the xylene tower 8 + Aromatics enter the ortho-xylene tower 5, the top pressure of the ortho-xylene tower 5 is 0.04Mpa (gauge pressure), the tower top temperature is 158°C, the tower bottom temperature is 206°C, and the reflux ratio (relative to the feed) is 1~ 3 (weight). The product coming out from the top of the ortho-xylene tower 5 direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com