Silicon rubber foam and producing method and use thereof

A manufacturing method and technology of silicone rubber, applied in application, medical science, shoe sole, etc., can solve the problems of lack of air permeability, poor repeated deformation, and difficulty in adjusting the size of openings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Manufacture of Silicone Rubber Foam

[0078]70% by weight of dimethylpolysiloxane, 25% by weight of xylene, and 5% by weight of tourmaline were mixed to prepare a silicone rubber solution.

[0079] In addition, polyurethane foam (shinhwaurethane, Korea) was immersed in 10 liters of the above-prepared silicone rubber solution for 5 minutes.

[0080] The above-mentioned polyurethane foam impregnated with the silicone rubber solution was repeatedly supplied twice to a pressure roller (hallaclimate control Korea), and then passed through a conveyor belt dryer (JIN VIBRO TECH Korea) for 10 minutes for hot air drying to finally produce a silicone rubber foam .

Embodiment 2

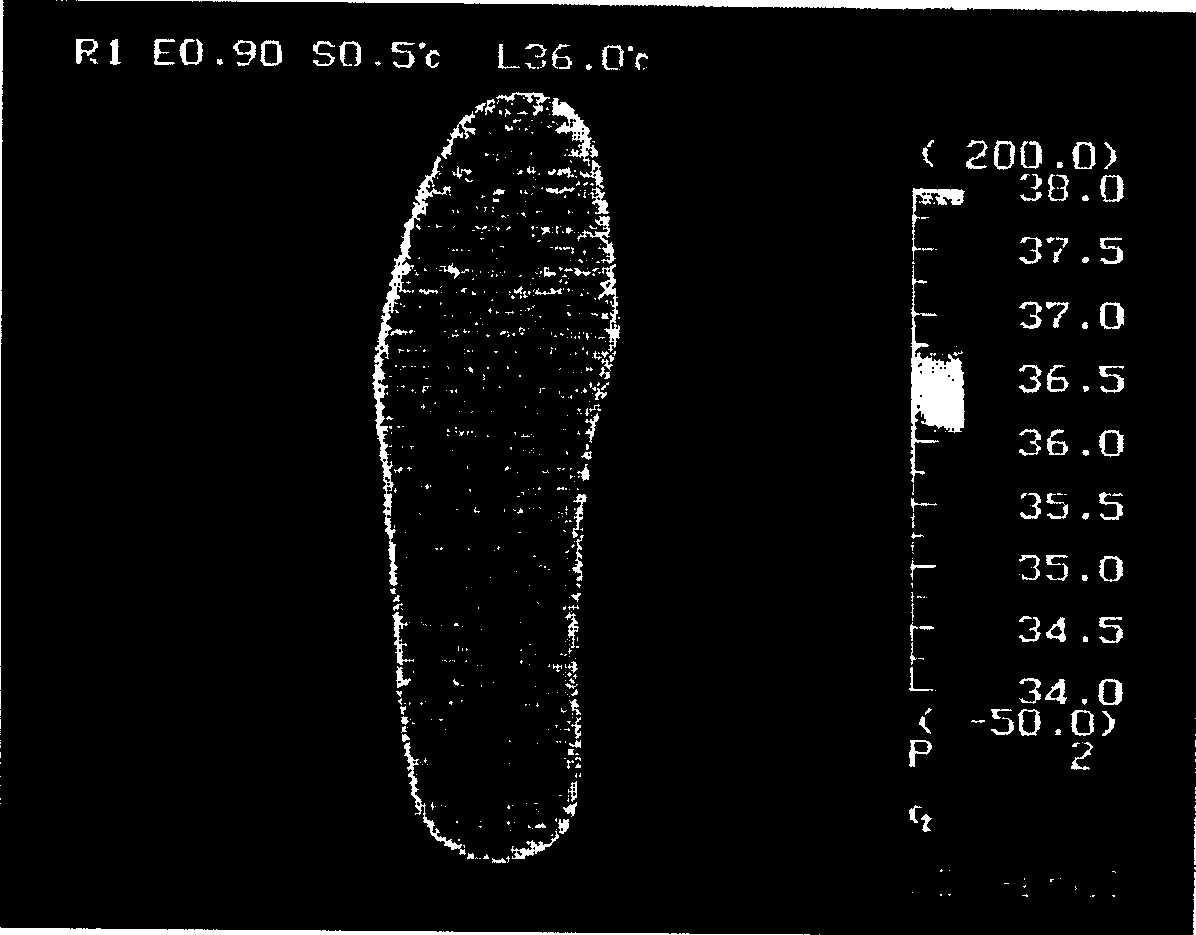

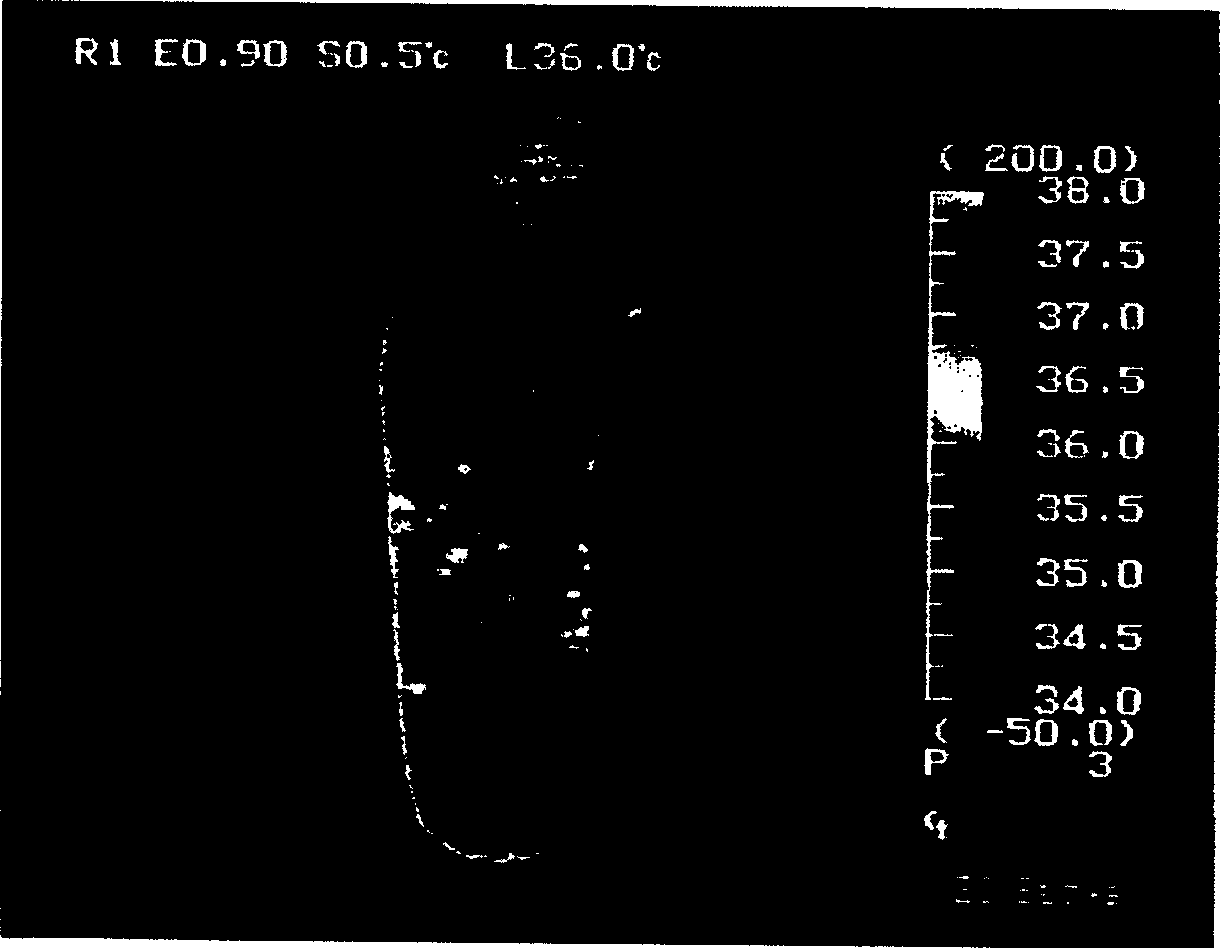

[0082] Far-infrared radiation measurement of shoe soles made of silicone rubber foam

[0083] Utilize the silicon rubber foam that manufactures in above-mentioned embodiment 1, manufacture shoe sole, with infrared camera, under the condition of temperature 29 ℃, humidity 41%, measure the infrared radiation energy that above-mentioned shoe sole emits. On the other hand, a normal shoe sole was used as a comparative example. The respective measurement results are shown in Figure 1a with Figure 1b middle.

[0084] Such as Figure 1a with Figure 1b Shown, emit a large amount of infrared energy ( Figure 1a ), while in the comparative example it was confirmed that the emission of infrared energy was very small ( Figure 1b ).

Embodiment 3

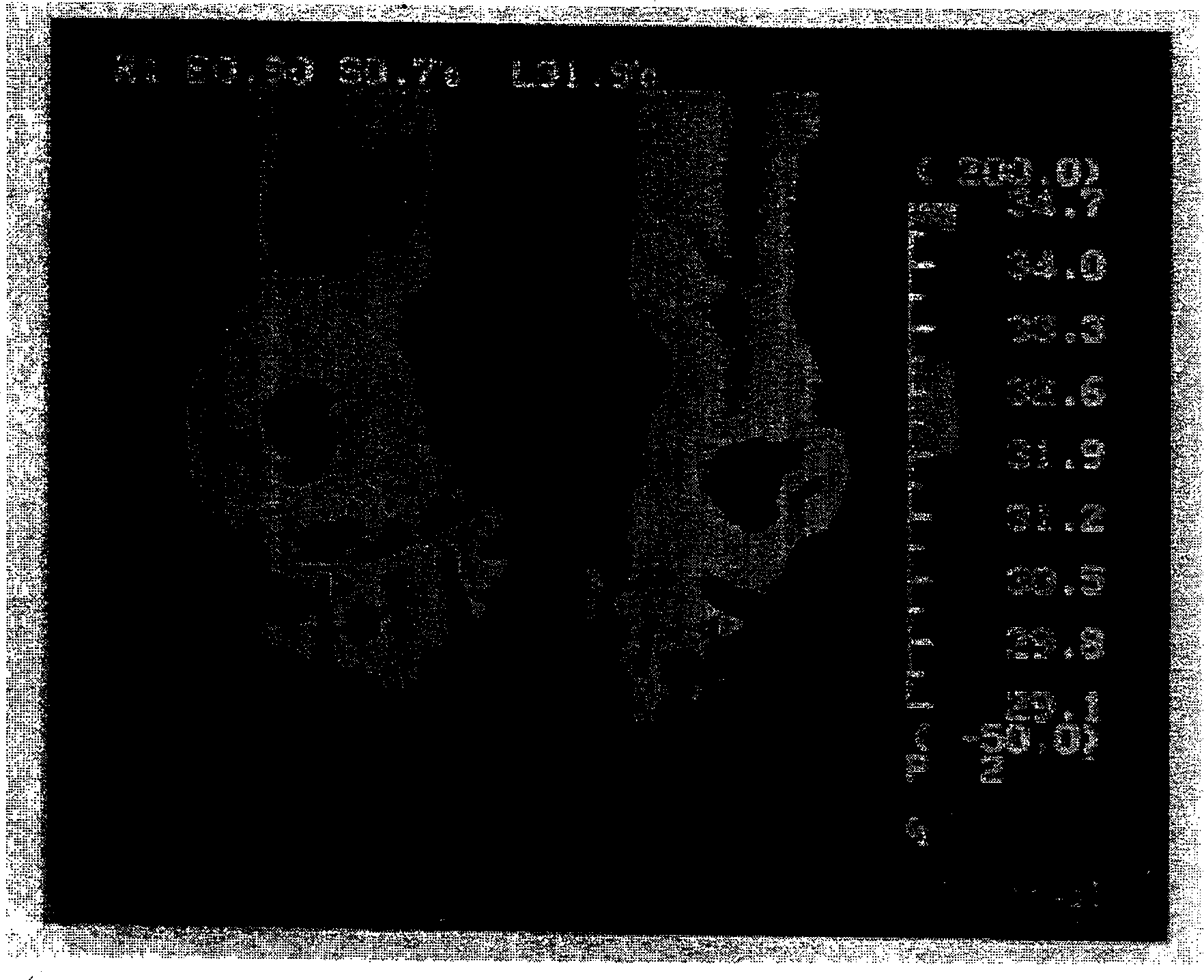

[0086] Far Infrared Radiation Measurement of Bracelets Made of Silicone Rubber Foam

[0087] Adopt the silicon rubber foam that makes in above-mentioned embodiment 1, manufacture bracelet, wear above-mentioned bracelet 10 minutes later, utilize digital body temperature camera at 25 ℃, under the condition of relative humidity 40%, the body temperature change near the wrist of photographing. On the other hand, a wrist without a bracelet was used as a comparative example. The measurement results are shown in figure 2 .

[0088] Such as figure 2 As shown, the blood flow of the wrist wearing the bracelet made of silicone rubber foam of the present invention is promoted, and body temperature rises ( figure 2 on the left side of ), while in the comparative example, it was confirmed that the rise in body temperature was very small ( figure 2 to the right of the ).

[0089] In addition, blood samples were collected before wearing the above-mentioned bracelet and after 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com