Electret capacitor microphone

A condenser microphone and electret technology, applied in the field of converters, can solve problems such as manufacturing difficulties, lower microphone failure temperature, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

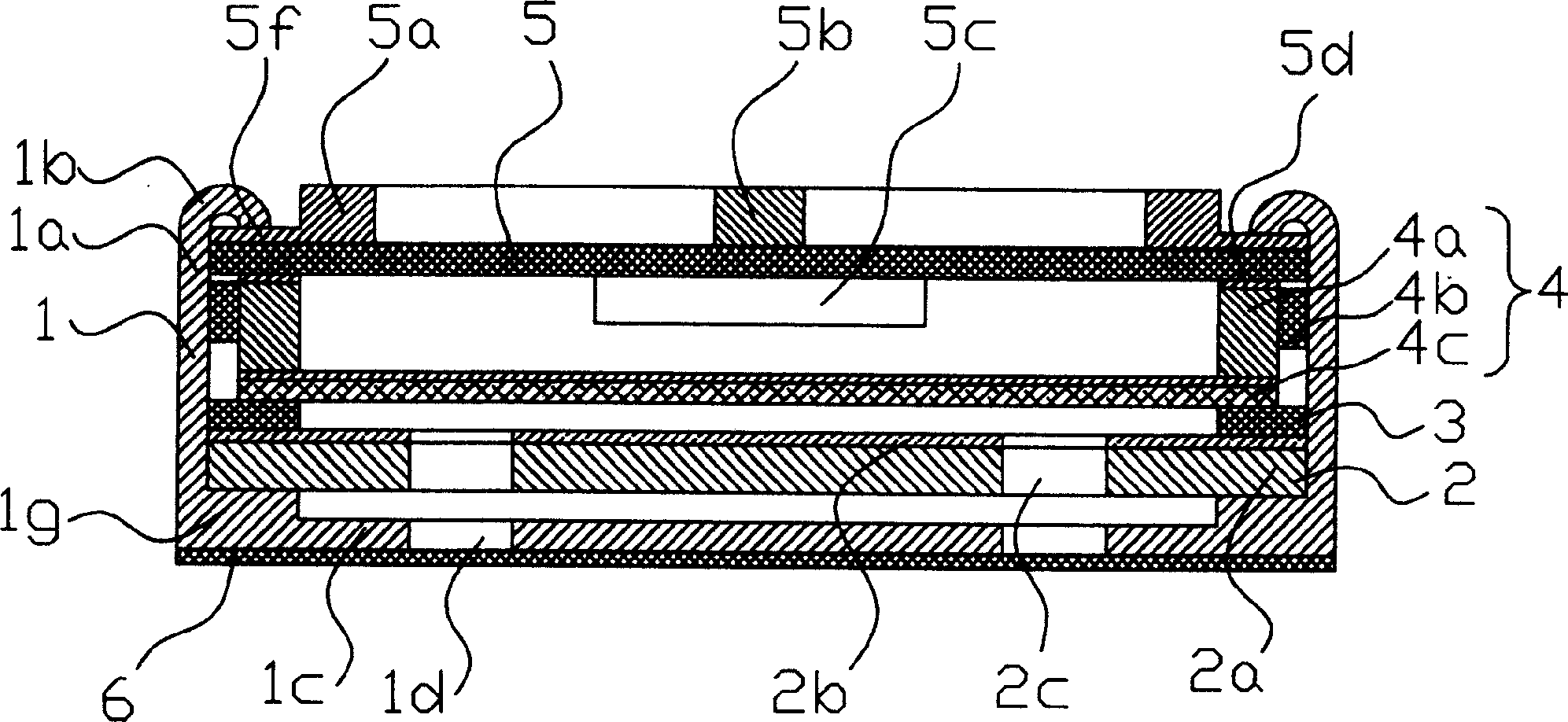

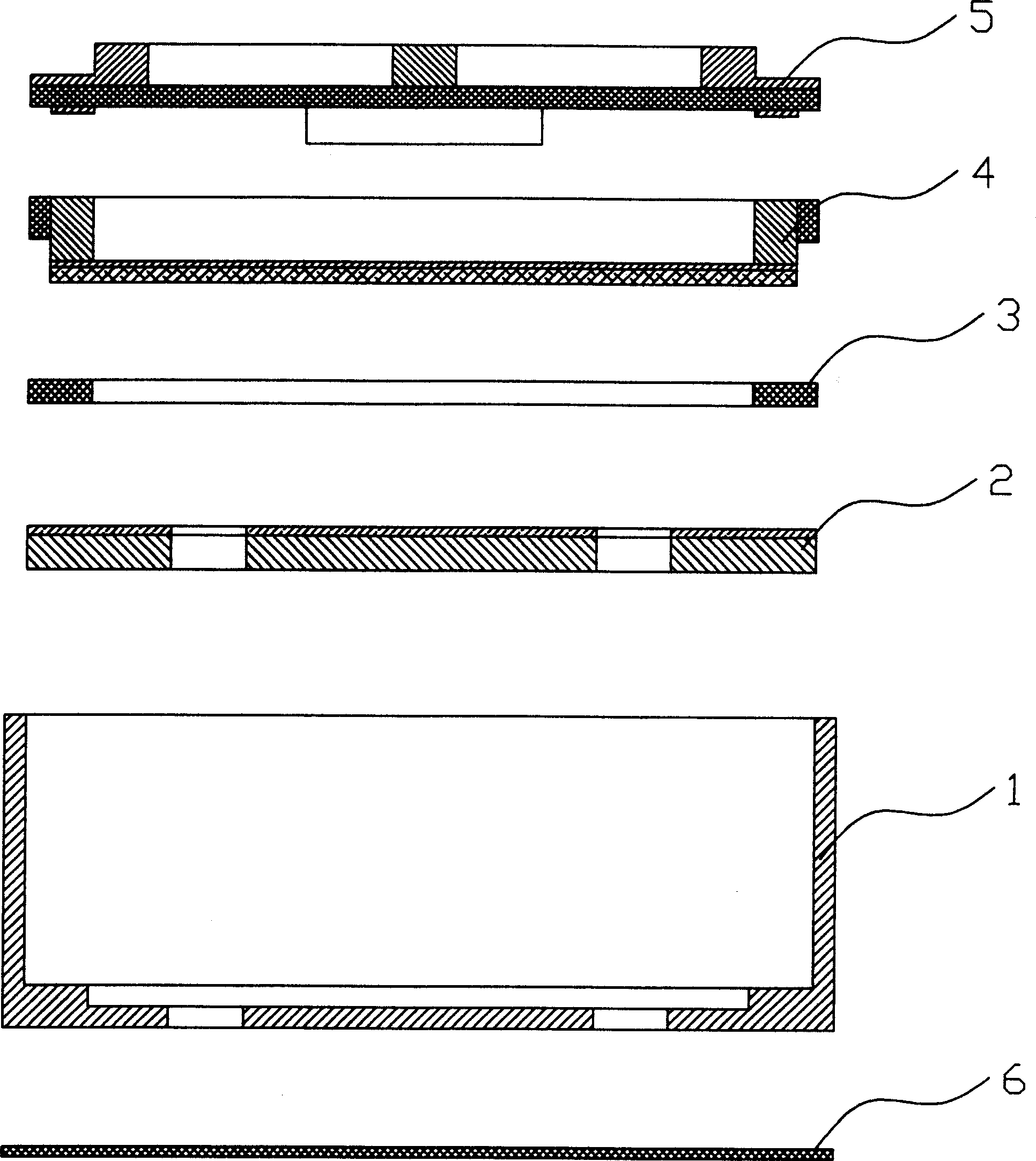

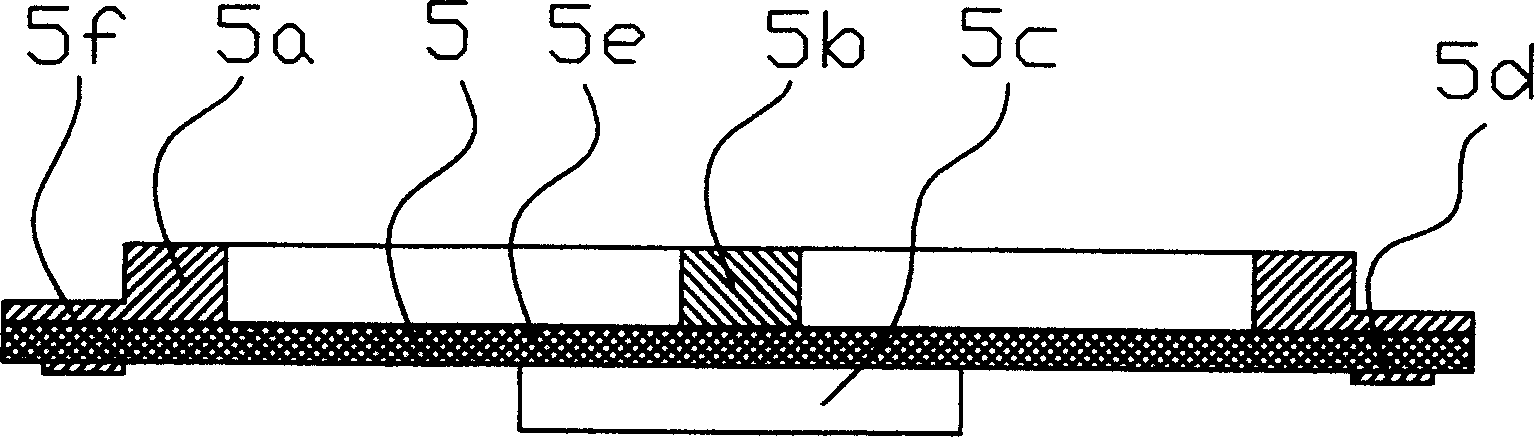

[0031] Such as figure 1 , figure 2 As shown, the electret condenser microphone includes a metal shell 1, and the shell 1 has a cylindrical side part 1a and a sound inlet part 1c, and the sound inlet part 1c is located at one end of the cylindrical side part 1a and is connected to the cylindrical side part 1a. The cylindrical side part 1a is integrated, the sound inlet part 1c is provided with a sound hole 1d, and the outer surface of the sound inlet part 1c is fixed with a dustproof net 6 to prevent dust from entering the microphone from the sound hole 1d ,Also includes

[0032] Such as Figure 7As shown, the back plate support part 1g, which is located inside the sound inlet part 1c and is ring-shaped, is used to support the back plate 2 and serves as an electrical connection part between the back plate 2 and the metal shell 1; The components are arranged so that the sound waves introduced by the sound hole 1d of the sound inlet part 1c on the metal shell 1 can be transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com