Mixed fiber and, stretch nonwoven fabric comprising said mixed fiber and method for manufacture thereof

A technology of non-woven fabrics and mixtures, applied in the field of elastic non-woven fabrics and sanitary materials, can solve the problems of filament breakage, spinnability (poor formability, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

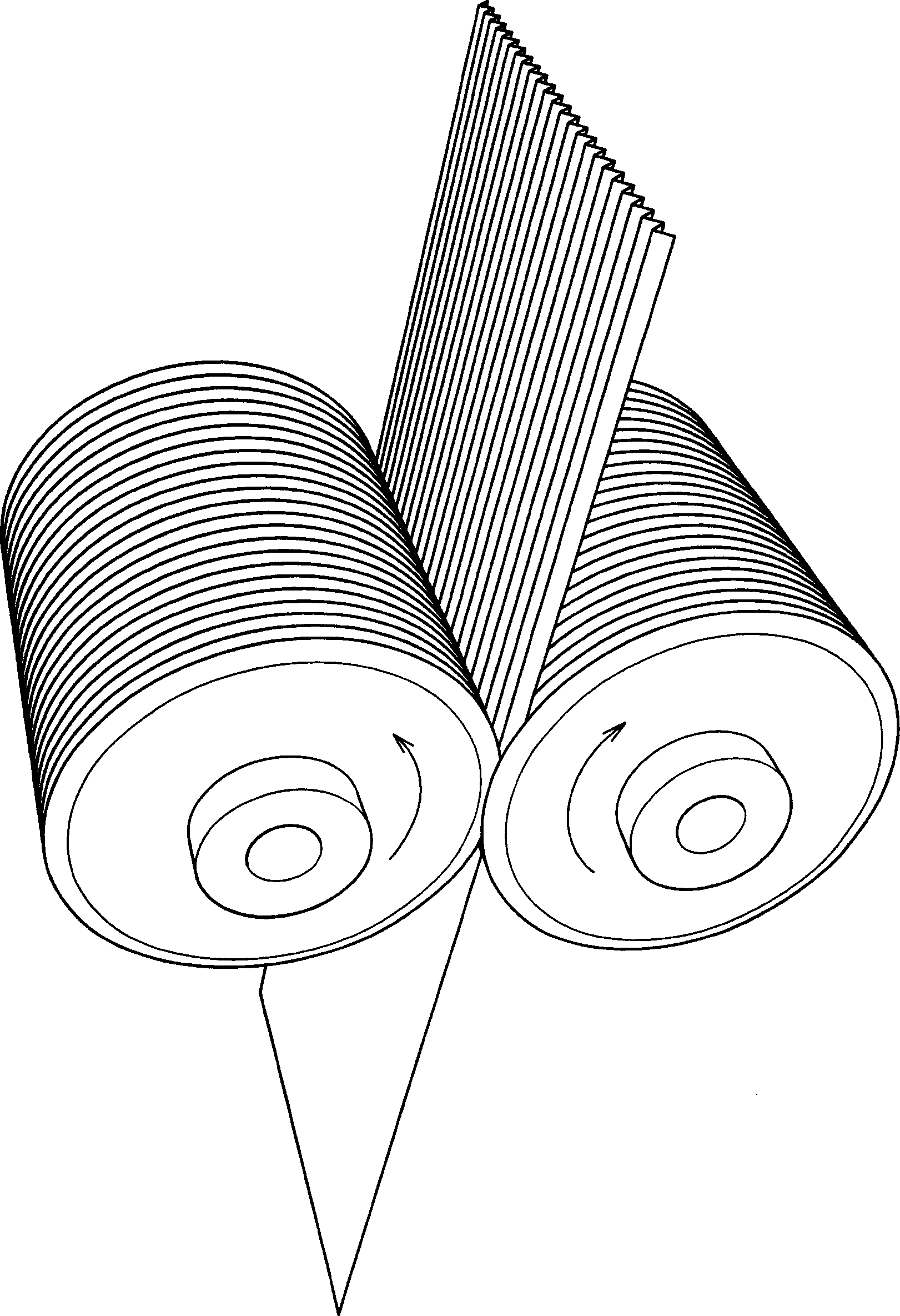

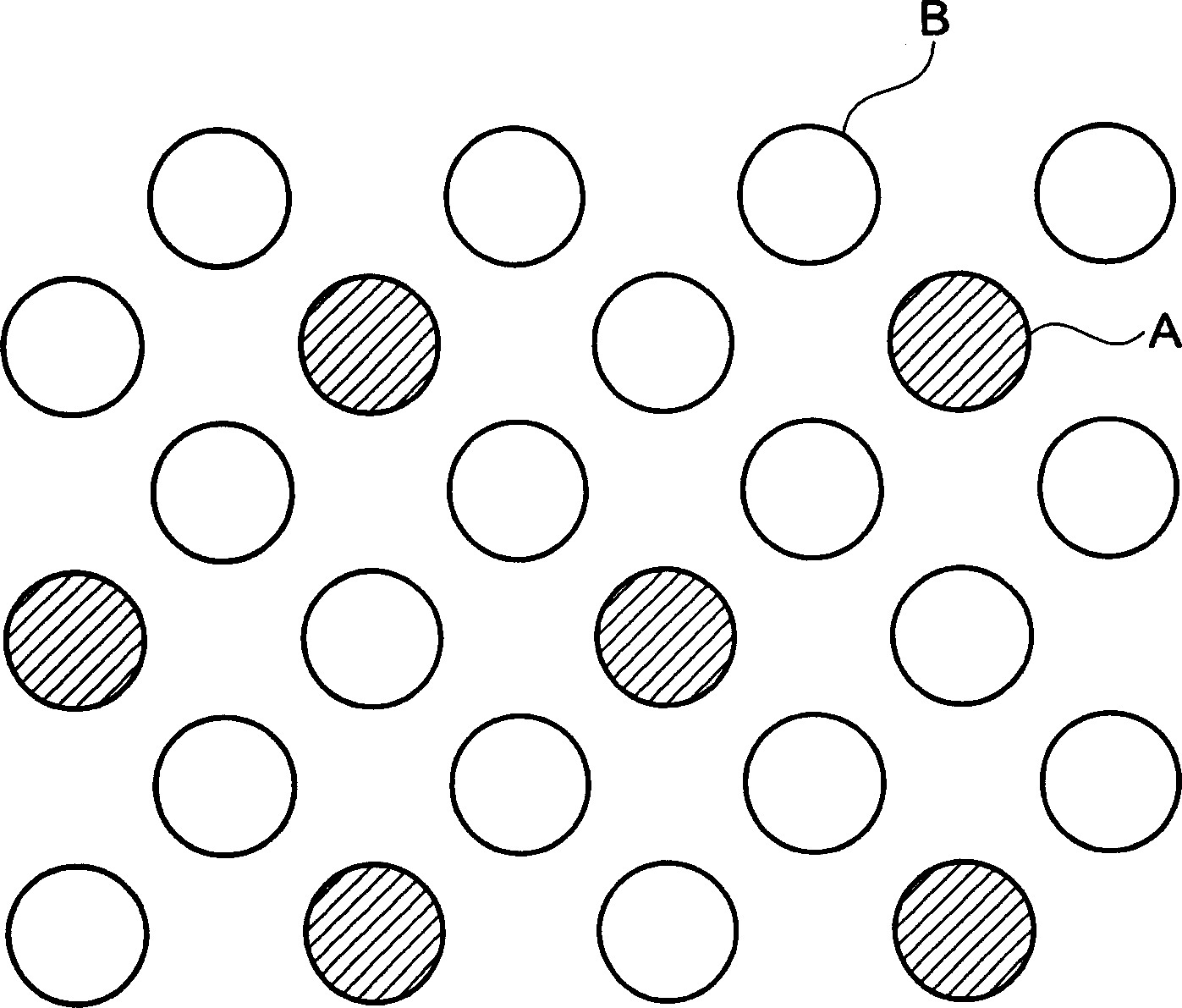

Method used

Image

Examples

Embodiment 1

[0174]In a nitrogen atmosphere, 280.3 parts by weight of 4,4'-diphenylmethane diisocyanate (hereinafter "MDI") (trade name: Cosmonate PH, available from Mitsui Takeda Chemicals, Inc.) was placed in an isocyanate compound storage tank (hereinafter Referred to as "tank A"), heat to 45°C with agitation to avoid air bubbles.

[0175] Separately, under a nitrogen atmosphere, in a polyol storage tank (hereinafter referred to as "tank B") was charged:

[0176] 219.8 parts by weight of polyester polyol having a number average molecular weight of 1000 (trade name: Takelac U2410, available from Mitsui Takeda Chemicals, Inc.);

[0177] 439.7 parts by weight of polyester polyol having a number average molecular weight of 2000 (trade name: Takelac U2420, available from Mitsui Takeda Chemicals, Inc.);

[0178] 2.97 parts by weight of bis(2,6-diisopropylphenyl)carbodiimide (trade name: Stabilizer 7000, available from RASCHIG GmbH);

[0179] 2.22 parts by weight of hindered phenolic antioxi...

Embodiment 2

[0188] In a nitrogen atmosphere, 288.66 parts by weight of MDI were introduced into tank A, heated to 45°C and agitated to avoid air bubbles.

[0189] Separately, under a nitrogen atmosphere, tank B was charged with:

[0190] 216.2 parts by weight of polytetramethylene ether glycol (trade name: PTG-1000, available from Hodogaya Chemicals) with a number average molecular weight of 1000;

[0191] 432.5 parts by weight of polyester polyol having a number average molecular weight of 2000 (trade name: Takelac U2720, available from Mitsui Takeda Chemicals, Inc.);

[0192] 2.22 parts by weight of Irganox 1010; and

[0193] 2.22 parts by weight of JF-83.

[0194] The contents were heated to 95°C with agitation. This mixture is referred to as polyol solution 2.

[0195] Next, 62.7 parts by weight of a chain extender 1,4-butanediol was introduced into tank C under a nitrogen atmosphere and heated to 50°C.

[0196] From the amount of these materials the amount of hard segments can b...

Embodiment 3

[0201] Under a nitrogen atmosphere, place the MDI in Tank A, heat to 45°C and agitate to avoid air bubbles.

[0202] Separately, under a nitrogen atmosphere, tank B was charged with:

[0203] 628.6 parts by weight of polyester polyol having a number average molecular weight of 2000 (trade name: Takelac U2024, available from Mitsui Takeda Chemicals, Inc.);

[0204] 2.21 parts by weight of Irganox 1010; and

[0205] 77.5 parts by weight of 1,4-butanediol.

[0206] The contents were heated to 95°C with agitation. This mixture is referred to as polyol solution 3.

[0207] From the amount of these materials the amount of hard segments can be estimated to be 37.1% by weight.

[0208] Thereafter, MDI and polyol solution 3 were supplied at constant flow rates of 17.6 kg / h and 42.4 kg / h, respectively, into a high-speed stirrer (Model SM40) whose temperature was controlled at 120 °C through the liquid supply line with a gear pump and a flow meter. . After mixing them by stirring a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com