Automatic calibrating device for positive branch confocal unstable resonator mirror

An automatic calibration, unstable cavity technology, applied in nonlinear optics, laser parts, optics, etc., can solve the problems of complex device, control algorithm, poor output beam quality, and difficulty in correcting multi-order aberrations. The effect of reducing the relative freedom of movement, saving control costs, and improving the efficiency of cavity adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

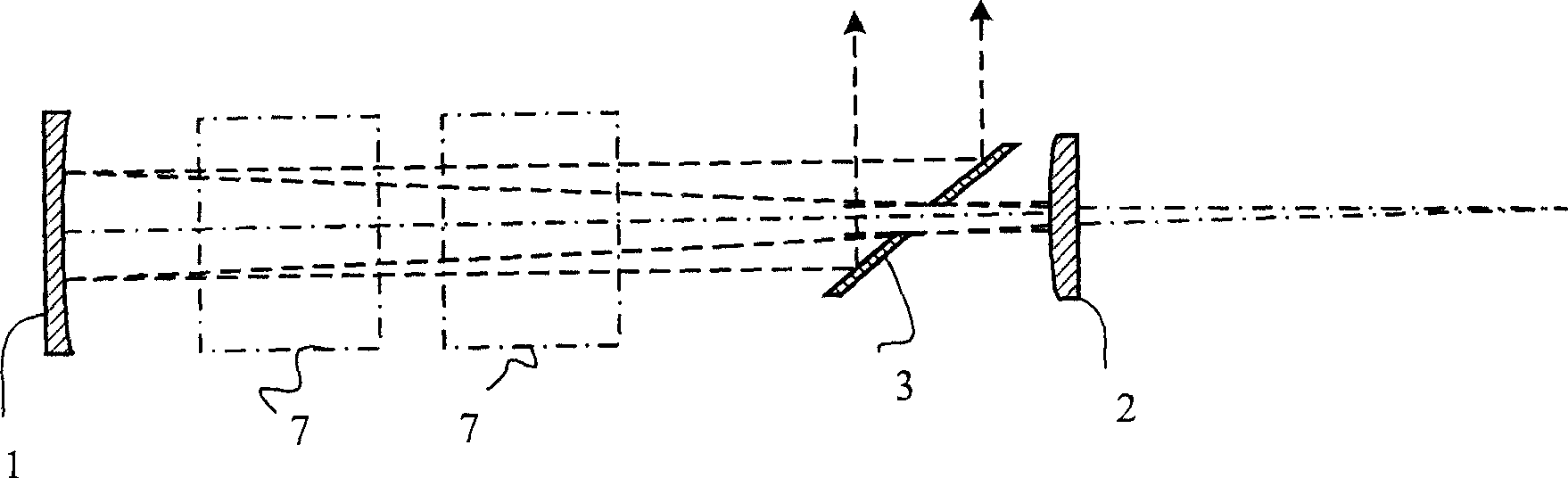

[0023] As shown in Figure 1, it is a schematic diagram of the structure of the current standard positive branch confocal unstable cavity. Since no folding mirror is used, the lateral dimension of the resonant cavity is relatively long;

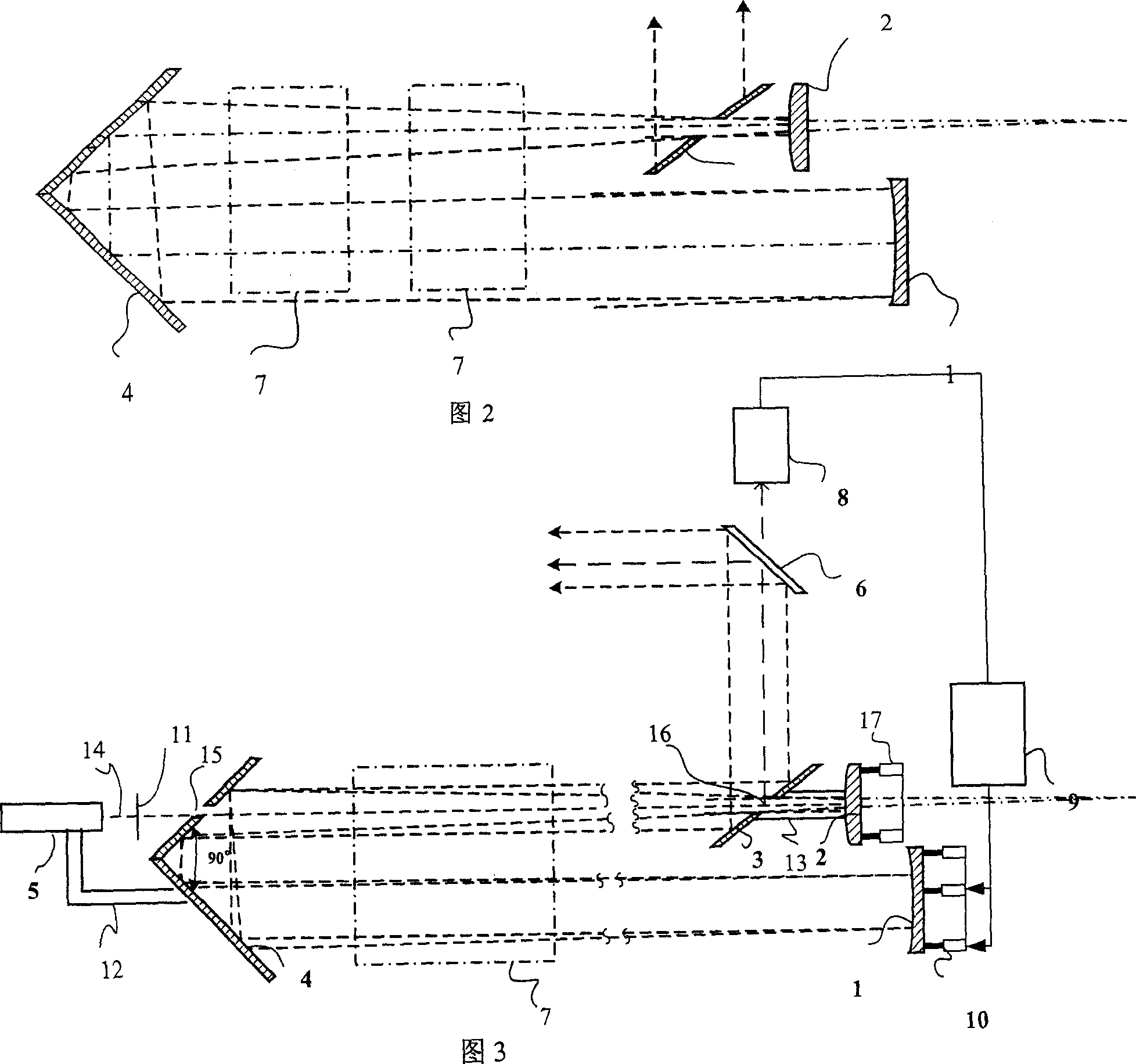

[0024] Figure 2 is figure 1 Schematic diagram of the improved structure of the non-stable cavity, that is, adding a folding mirror, which improves the working efficiency of the resonator and shortens the lateral size of the resonator. It is the optical path diagram of the resonator without considering the automatic calibration system in the cavity;

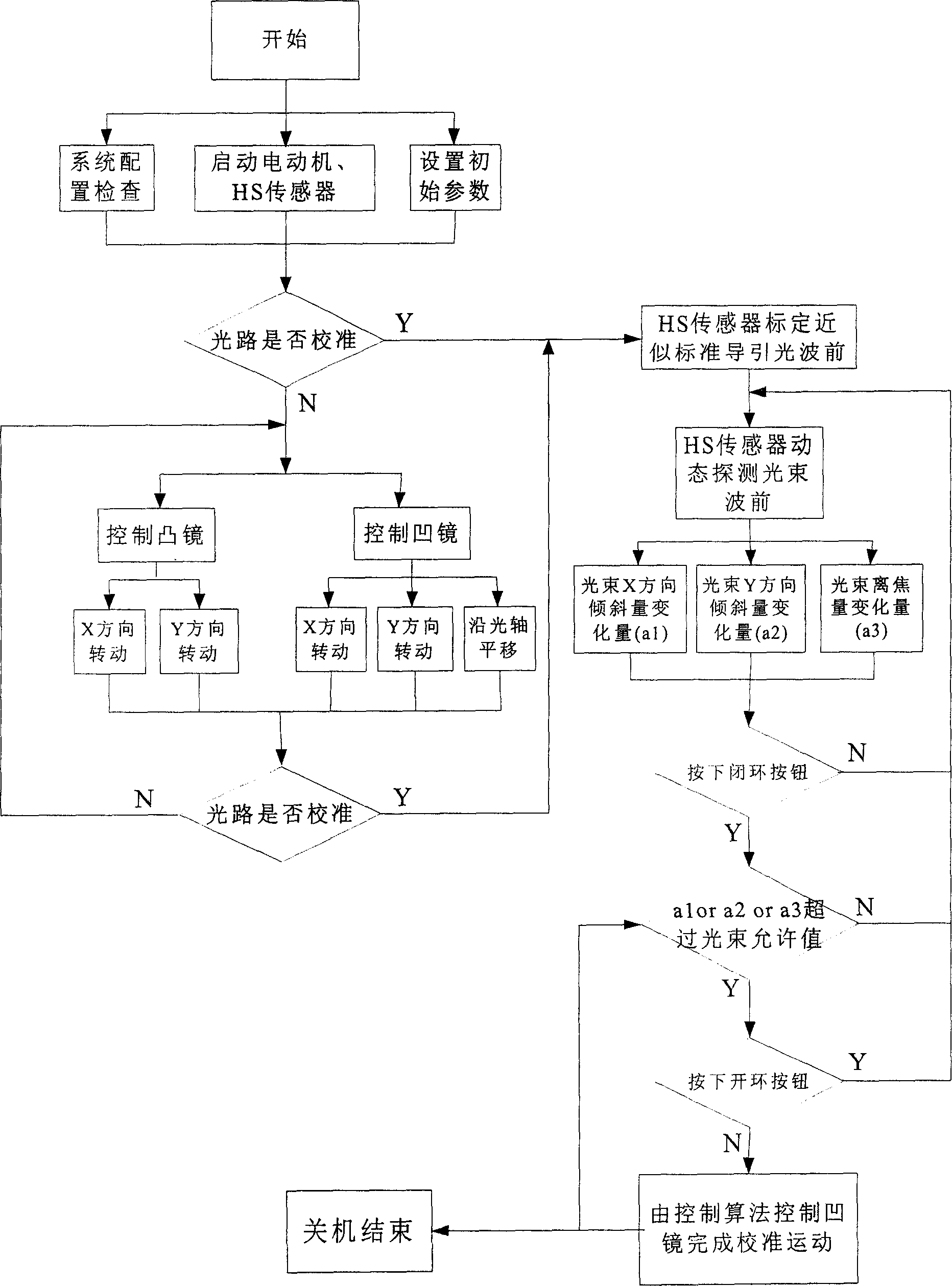

[0025] As shown in Figure 3, the present invention consists of a He-Ne laser 5, an intracavity folding mirror 4 with a small hole 15 structure, a scraper mirror 3 with a small hole 16, a convex mirror 2, and a Hart detector for detecting the output beam quality of the laser. Mambo front sensor 8, main controller 9 and concave mirror 1 with stepper motor actuator three-position adjustment frame 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com