Forging process of cooker

A utensil and cooking technology, which is applied in the manufacturing process of cooking utensils, can solve the problems of insufficient rigidity, waste of raw materials, and inability to ensure connection, etc., and achieve the effect of strong and durable shape, not easy to break, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with embodiment and accompanying drawing, process of the present invention will be further described:

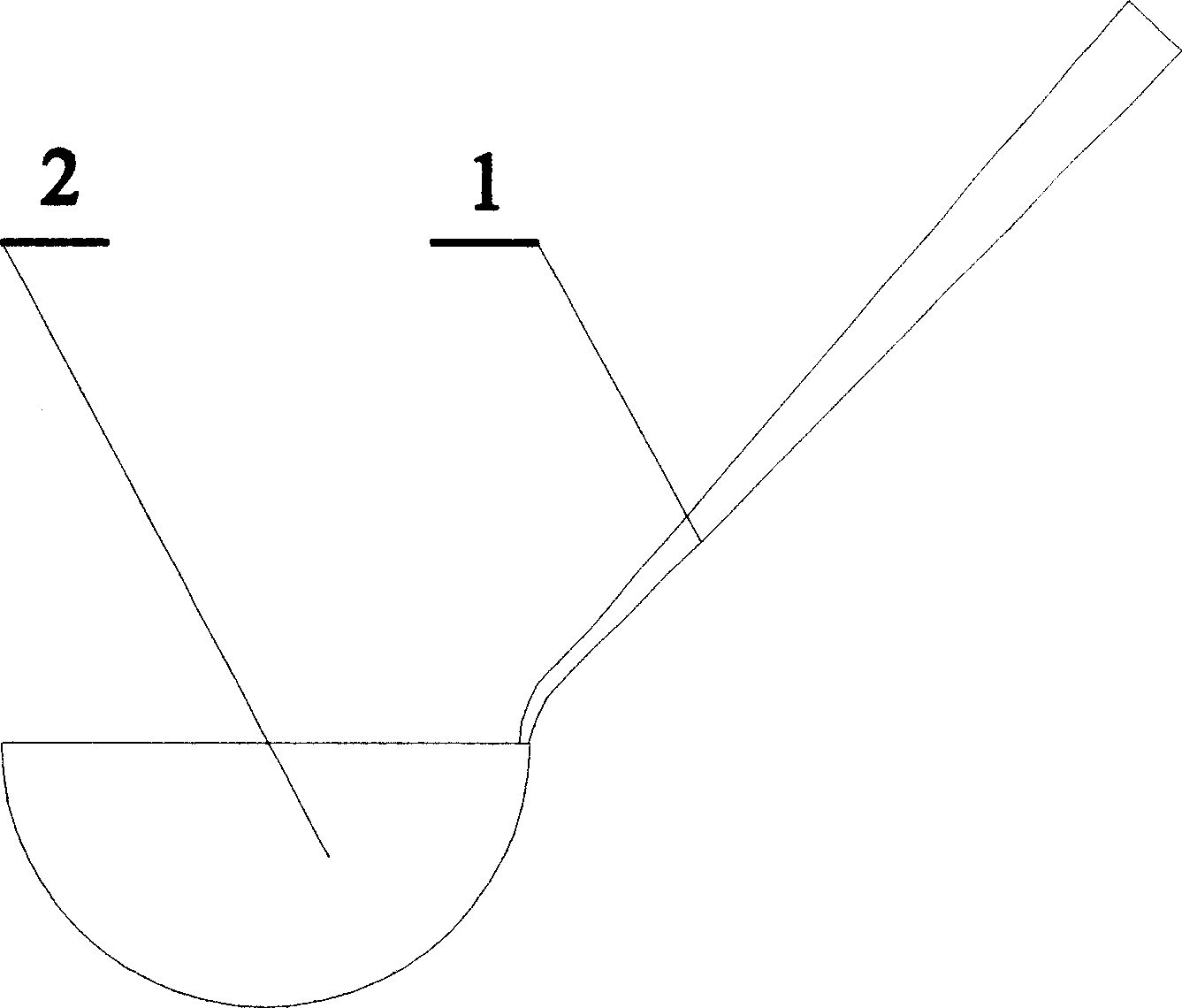

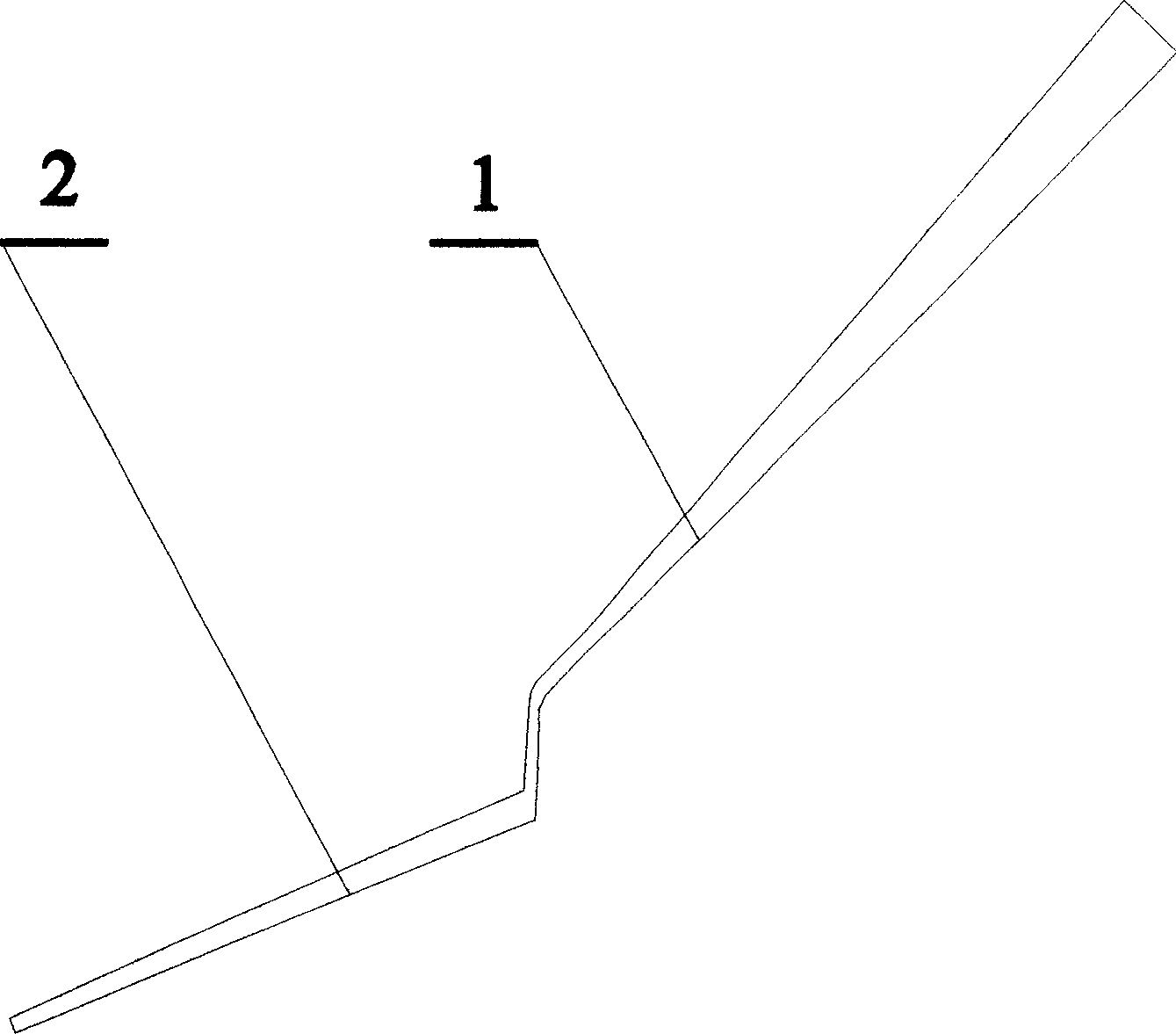

[0008] The invention relates to a forging process of cooking utensils, which can be used to forge frying shells / shovels of cooking utensils. The fried shell / fried shovel produced by it includes two parts, the handle 1 and the shell shovel body 2, such as figure 1 Shown is the fried shell manufactured by applying this forging process, such as figure 2 Shown is the frying shovel manufactured by applying this forging process. The process is realized in this way: use steel plate, stainless steel or other metal plate scraps with a thickness of 3-20mm to cut, heat to 650-800°C, and control it below the melting point of the material used for forging, so repeatedly forging for 4 ~8 times to make it into a whole billet shape, and also effectively remove impurities in the metal, so that the grains of the steel plate or stainless steel or other metal plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com