Intelligent optimized control method for comprehensive production index in ore dressing process

A technology of intelligent optimization and control method, applied in the direction of adaptive control, computer control, general control system, etc., can solve the problem that the production index and optimization cannot be achieved in the beneficiation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

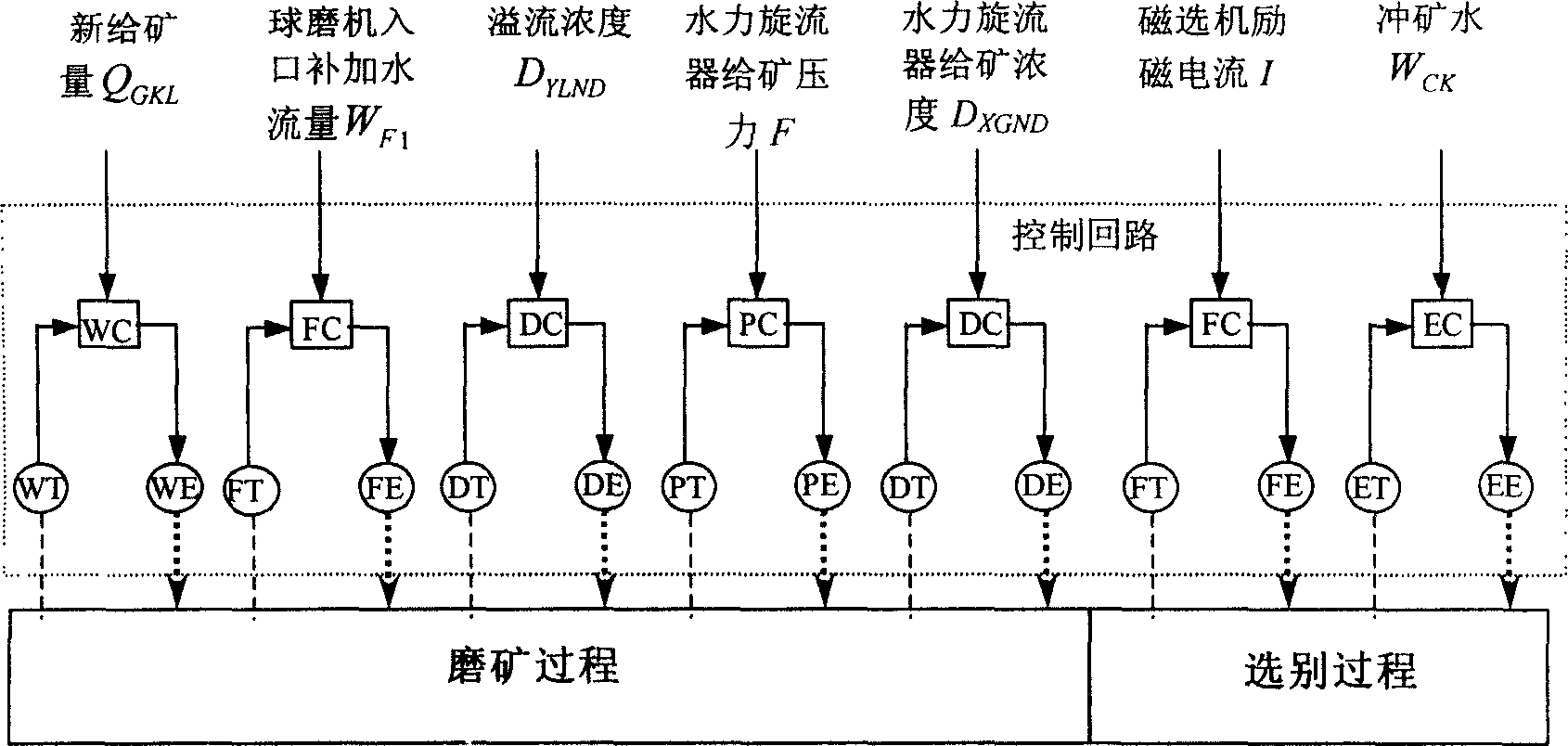

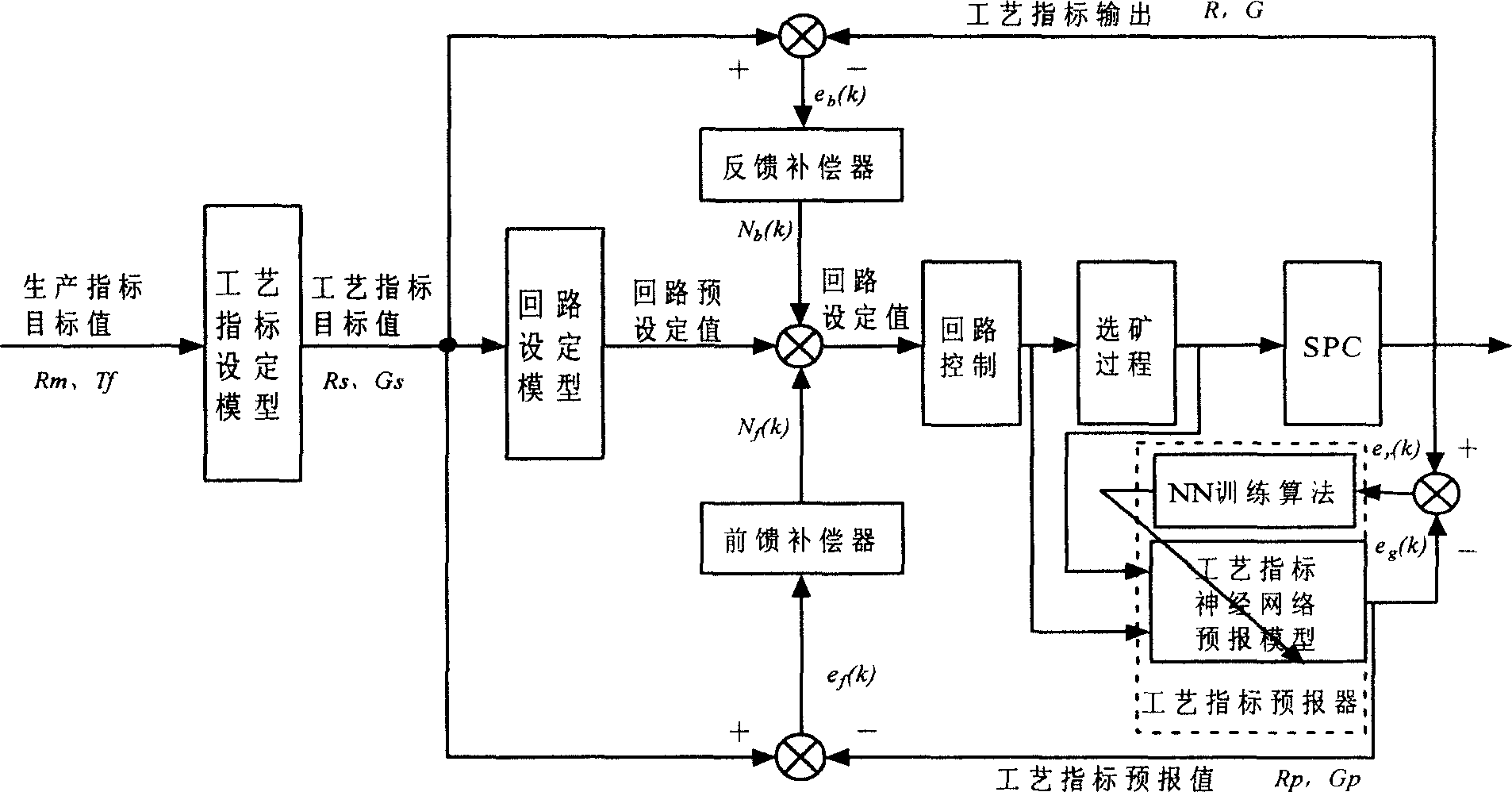

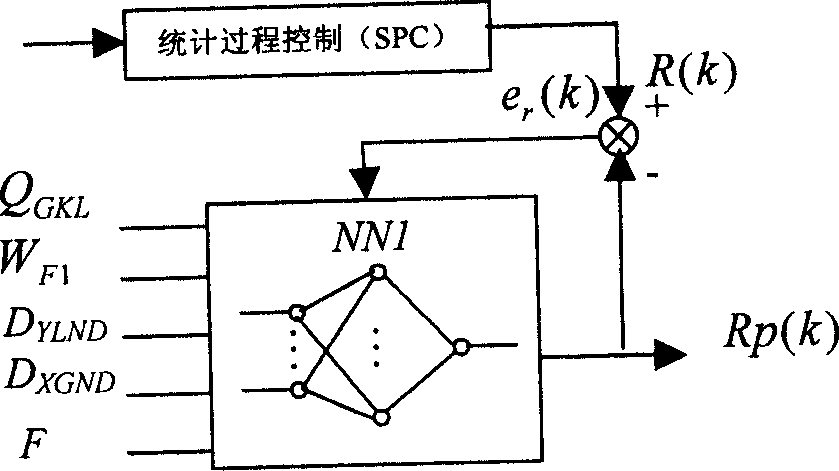

[0139] Embodiment of the present invention is a large-scale iron ore dressing plant. The raw ore of this concentrator is mainly pyrite and limonite, and the gangue is mainly barite, quartz, jasper and iron dolomite. The actual iron content of the ore is 33%. After the raw ore is pretreated (screening, magnetization roasting, etc.), it is transported to the cylindrical ore bin. The ore in the cylindrical ore bin is discharged by the electric vibration feeder, and then sent to the grinding process by the ore feeder belt conveyor. The grinding process consists of two stages of grinding circuits, and the first stage of grinding consists of a ball mill and a spiral classifier. The ore in the cylindrical ore bin is sent to the ore belt conveyor into a section of ball mill, which is mixed with the supplementary water at the entrance of the ball mill and ground into a slurry in the ball mill. The ore grinding in this section adopts a grid-type ball mill. The classifier and the spiral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com