Treatment method of soybean lactalbumin waste water

A technology for soybean whey wastewater and soybean whey water, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, infiltration/dialysis water/sewage treatment, etc. The protein cannot be completely precipitated and other problems, so as to reduce the load, reduce energy consumption, and increase work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

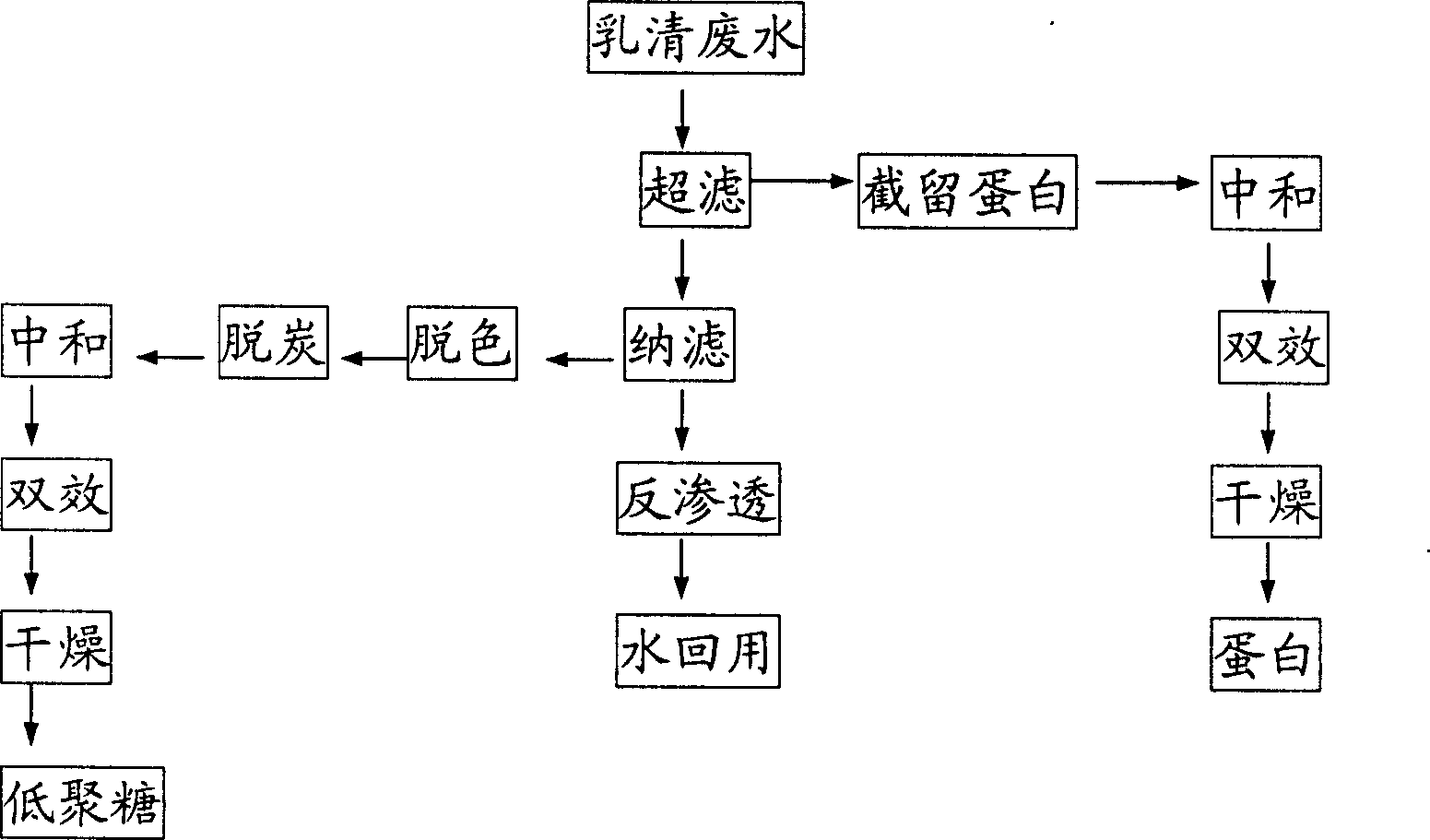

[0026] A production plant with an annual output of 2,500 tons of soybean protein isolate, producing 250m of soybean whey water per day 3 , of which protein is 0.41%, total sugar is 0.77%, including oligosaccharides is 0.63%, and sucrose is 0.14%. It is designed to work 20 hours a day, and the average whey is 12.5m per hour. 3 . First, the whey water is pumped into the ultrafiltration membrane separation system for treatment. The ultrafiltration membrane is an inorganic ceramic composite membrane with a molecular weight cut-off of 10KD and is highly resistant to protein pollution. The separated concentrate has 15m 3 , which contains 5.8% protein, sent to the protein storage tank to adjust the pH value to neutral, after double-effect evaporation and concentration, it will be spray-dried to obtain 1.3 tons of protein powder with a protein content of 65%; the filtrate after ultrafiltration separation is 230m 3 Handed over to the nanofiltration membrane separation system, the nan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com