Production process of azoic disperse dye

A disperse dye and production process technology, applied in the preparation of azo dyes, azo dyes, coupling reactions of azo dyes, etc., can solve difficult problems such as governance, achieve high automation, high efficiency, and increased manageability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0038] The esterification liquids are: dark blue esterification liquid, red jade esterification liquid, and yellow palm esterification liquid.

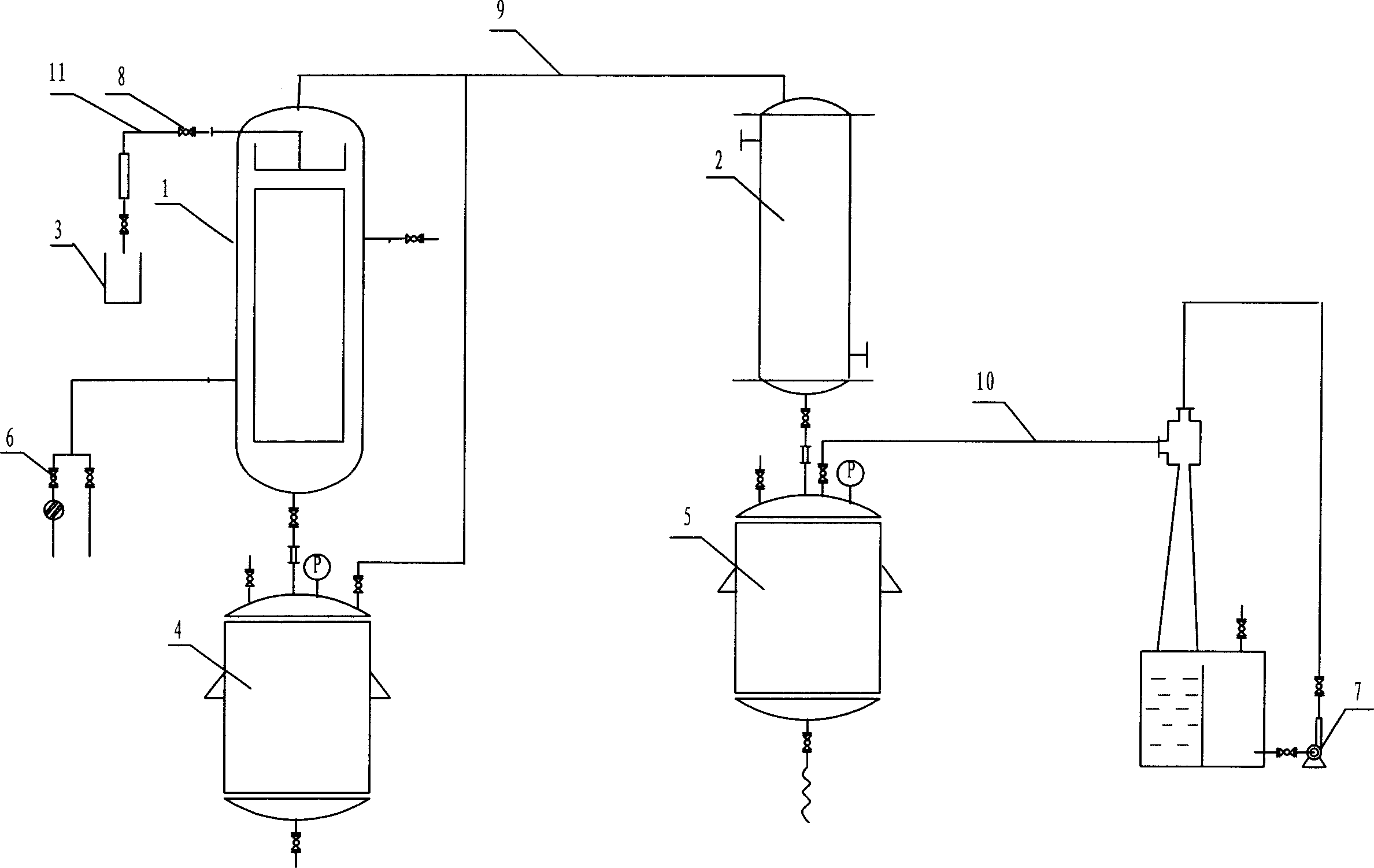

[0039] refer to figure 1 And according to the process parameters shown in Table 1, open the steam trap 6, open and adjust the steam inlet valve of the evaporator, let the main body of the evaporator 1 preheat for 30 minutes, open the vacuum inlet valve, press the start button of the vacuum pump 7 to start vacuuming, and pass Pipeline 10 makes the condenser and evaporator work under negative pressure. Open and adjust the feed valve 8, the esterification liquid enters the evaporator 1 through the pipeline 11 from the storage tank 3 (preheated to 80°C), and the distributor rotating on the upper part of the evaporator 1 is forced to fall into the film, continuously and evenly It is distributed on the evaporation surface (inner wall surface of the cylinder) in a turbulent flow, and finally flows into the esterification liquid receiving ta...

Embodiment 4~6

[0041] The esterification liquids are: dark blue esterification liquid, red jade esterification liquid, and yellow palm esterification liquid.

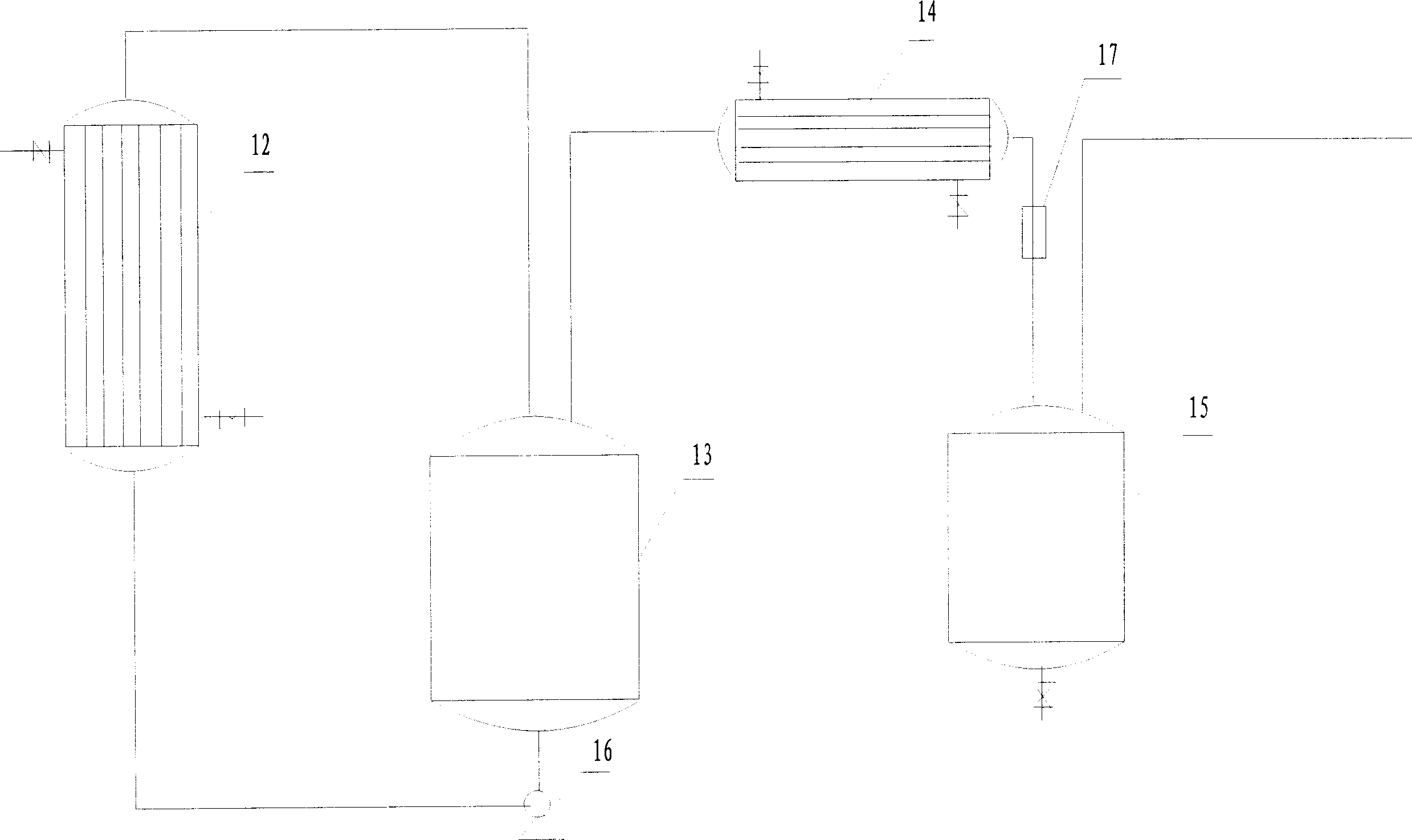

[0042] refer to figure 2 And according to the process parameters shown in Table 1, feed steam into the heat exchanger 12 for preheating, and adjust the steam pressure through the steam inlet valve, pump the esterification liquid in the storage tank 13 into the heat exchanger 12 with a pump 16, Adjust the feed valve to control the feed amount. After sufficient heat exchange between the esterified liquid and the steam, it returns to the storage tank 13 for circulation. Under negative pressure, the volatilized acetic acid enters the condenser 14 through the pipeline, and after condensation Flow into receiving tank 15, until there is no acetic acid dripping in the sight glass 17, close the vacuum system.

Embodiment 7~9

[0044] The esterification liquids are: dark blue esterification liquid, red jade esterification liquid, and yellow palm esterification liquid.

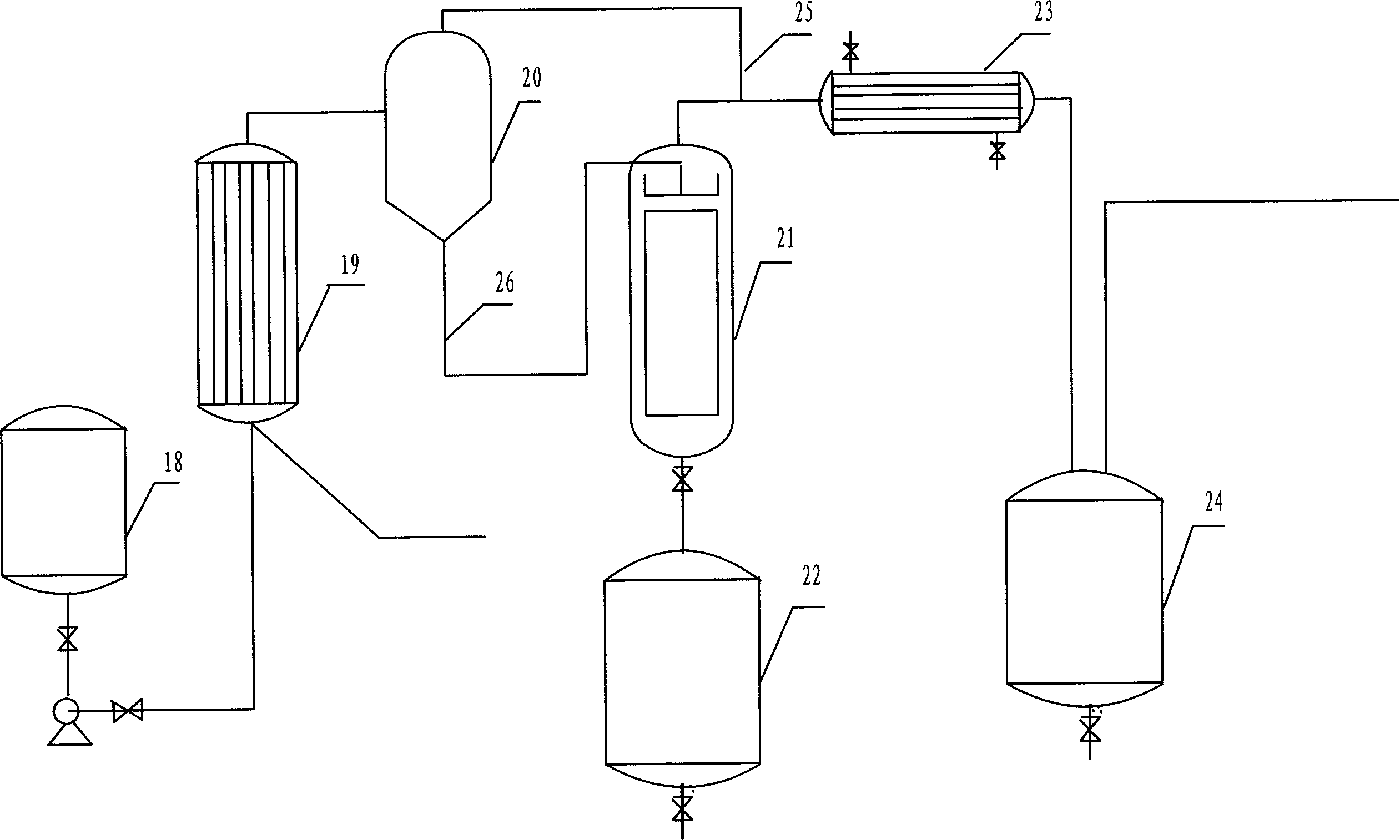

[0045] refer to image 3 And according to the process parameters shown in Table 1, the esterification liquid is pumped into the heat exchanger 19 from the storage tank 18. After sufficient heat exchange, it enters the flash chamber 20 under negative pressure, and part of the acetic acid vapor Under vacuum conditions, directly enter the condenser 23 through the pipeline 25 to condense and then return to the receiving tank 24; the remaining esterified liquid in the flash chamber enters the evaporator 21 through the pipeline 26 to continue to evaporate, and the vapor pressure of the evaporator is controlled. Feed amount. After the esterification liquid is fully heat-exchanged with the steam again in the evaporator 21, the acetic acid vapor is drawn from the upper part of the evaporator 21 into the condenser 23, and recovered in the rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com