Nanometer SiO2 powder dispersion method

A powder material and nano technology, which is applied in the field of dispersion of nano SiO2 powder materials to achieve the effects of improving mechanical properties, convenient operation and reducing modification conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

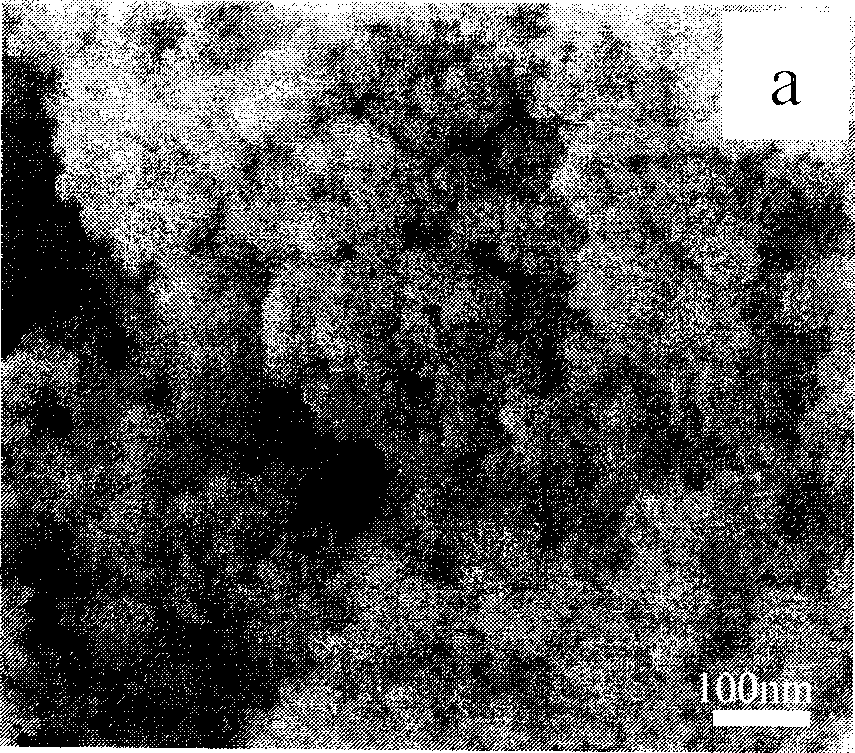

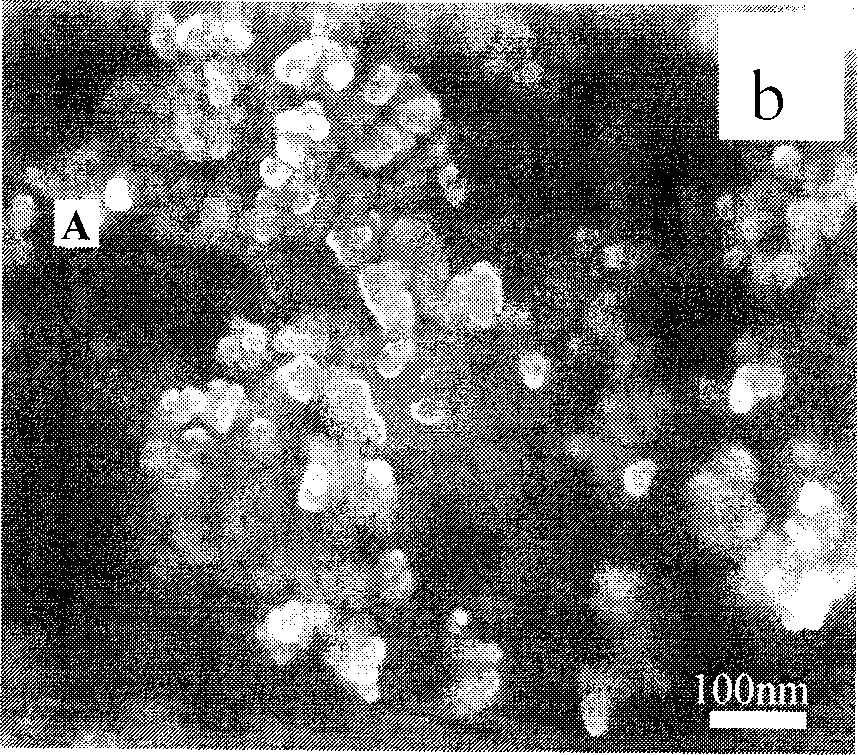

Image

Examples

Embodiment 1

[0013] The first step, inorganic coating: add 1L of nano-SiO with a solid-to-liquid ratio of 50g / L in a reaction kettle with a stirring device and a liquid flow tube 2 Sol, 20ml concentration is 0.03mol / L Al(NO 3 ) 3 9H 2 O is dripped from the liquid flow tube, and the pH value of the reaction solution is adjusted by urea aqueous solution to keep it between 7.5 and 8.0. At a temperature of 75°C, react for 2 hours to make Al(OH) 3 Coated in nano-SiO 2 The particle surface, after the reaction, was first washed with deionized water, then dehydrated with absolute ethanol, and then dried to constant weight at a temperature of 110°C, first washed with deionized water, then dehydrated with absolute ethanol, and then Dry to constant weight at 110°C to obtain surface-coated Al(OH) 3 nano-SiO 2 Powder.

[0014] The second step. Organic modification: first add sodium dodecylbenzenesulfonate (SDBS) with a mass percentage of 0.5% into a reactor with a stirring device, then add a cert...

Embodiment 2

[0016] According to the processing method of embodiment 1, Al(NO 3 ) 3 9H 2 The concentration of O is 0.03 mol / L, and the addition amount of sodium dodecylbenzenesulfonate (SDBS) is 1.0% (wt%).

Embodiment 3

[0018] According to the processing method of embodiment 1, Al(NO 3 ) 3 9H 2 The concentration of O is 0.03 mol / L, and the addition amount of sodium dodecylbenzenesulfonate (SDBS) is 1.5% (wt%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com