Method and apparatus for using optical tweezers to manipulate materials

A technology of equipment and light beams, applied in the direction of biochemical equipment and methods, special-purpose bioreactors/fermenters, optics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

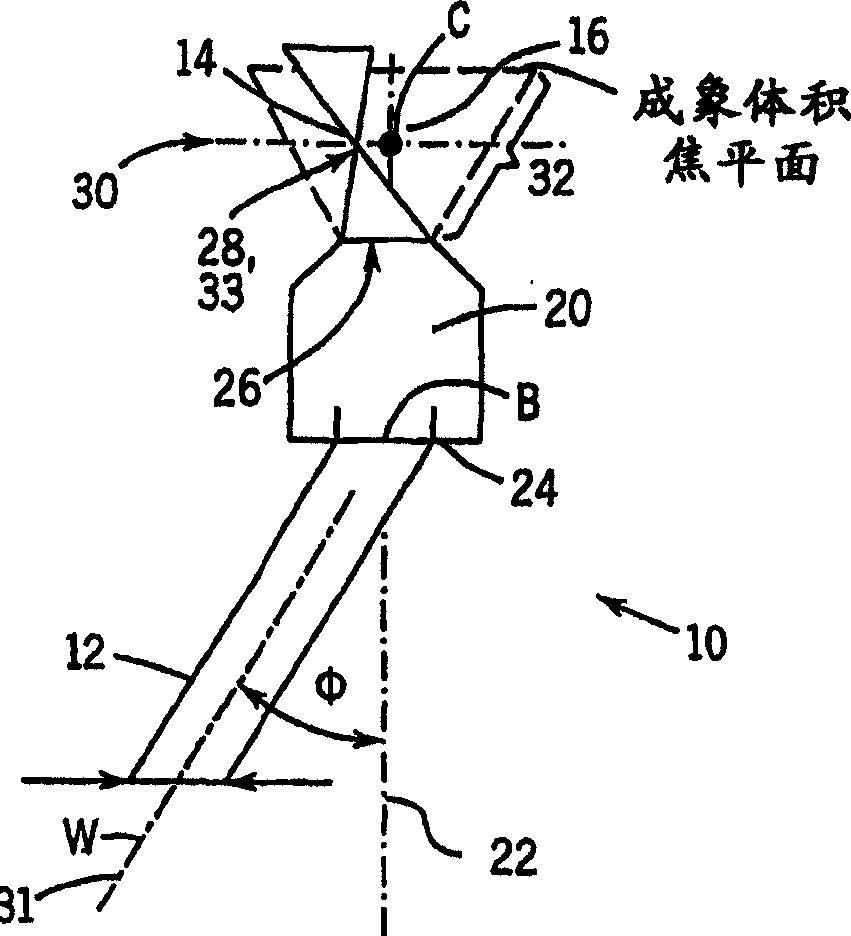

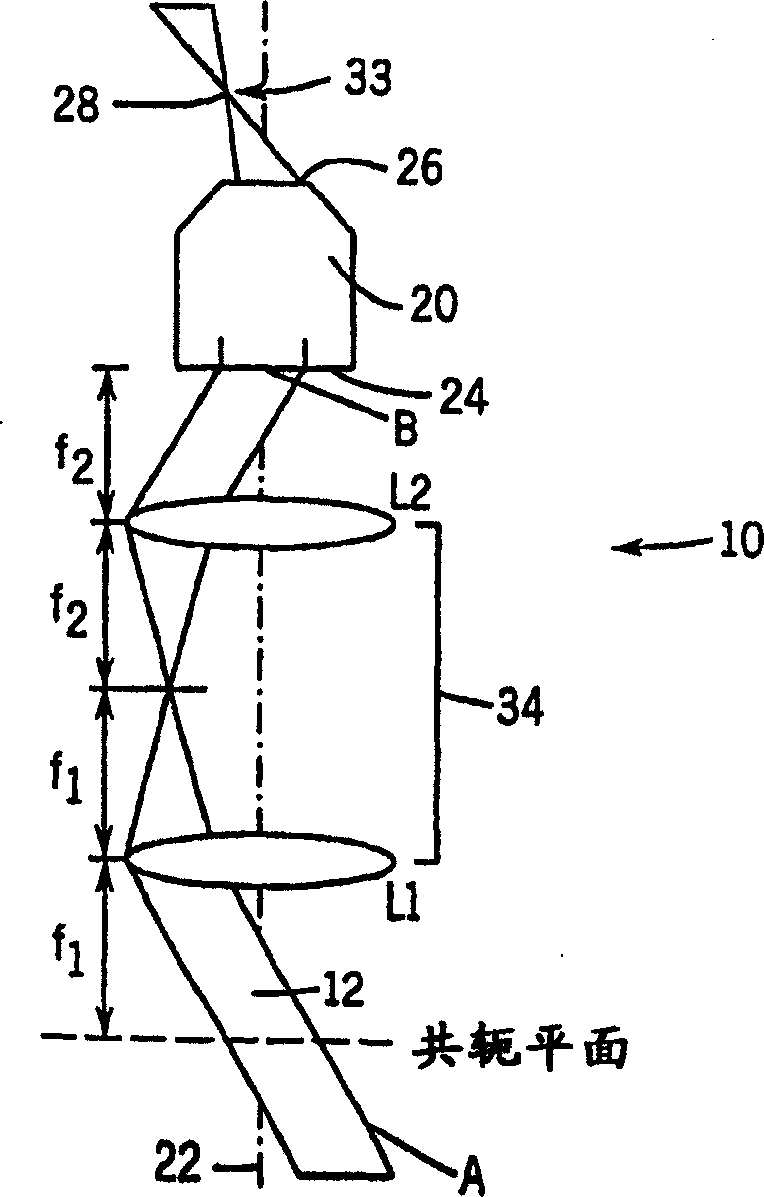

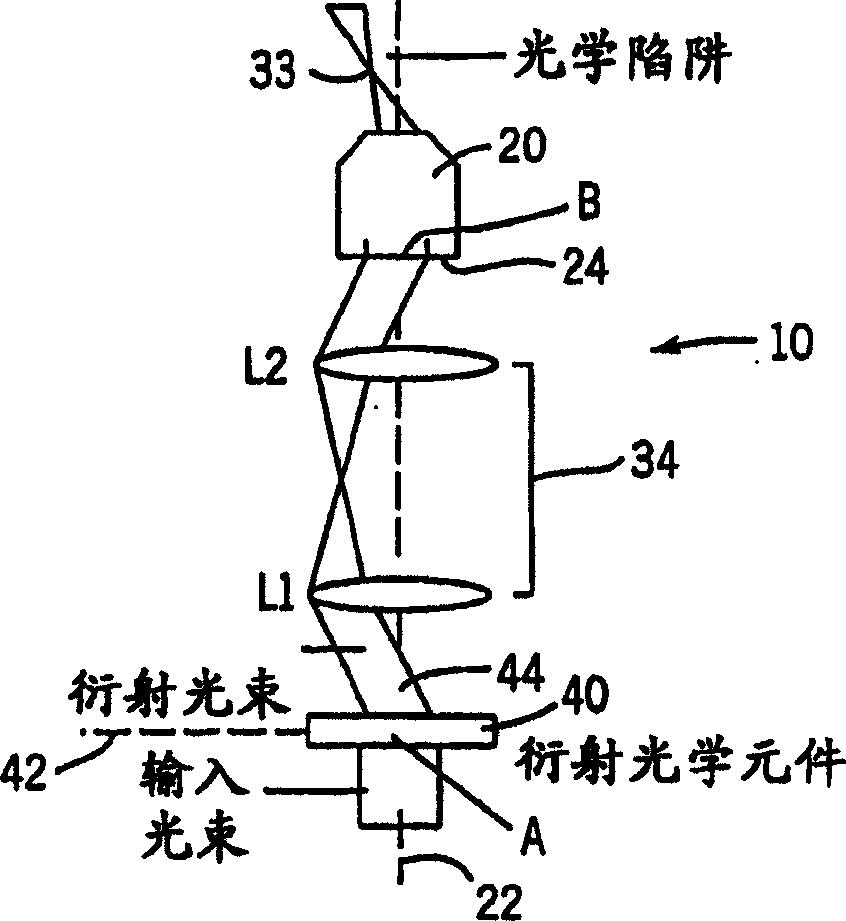

[0032] In order to better understand the improvement of the present invention, figure 1 and 2 Several methods and systems of the prior art are described. exist figure 1 In the optical tweezer system 10 of , the optical gradient force is generated due to the controllable manipulation of small dielectric particles 14 dispersed in a medium 16 using a single beam 12, wherein the medium has a refractive index n m smaller than the refractive index of the particle 14. The fundamental properties of optical gradient forces are well known, and of course in general terms the principle can manipulate reflection, absorption and low dielectric constant particles. Any of these techniques may be implemented in the description of the improvements of the invention described below, and the terms optical clamp, optical trap and optical gradient force trap will be used for description hereinafter.

[0033] The optical clamp system 10 is applied by using a light beam 12, such as a laser beam or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com