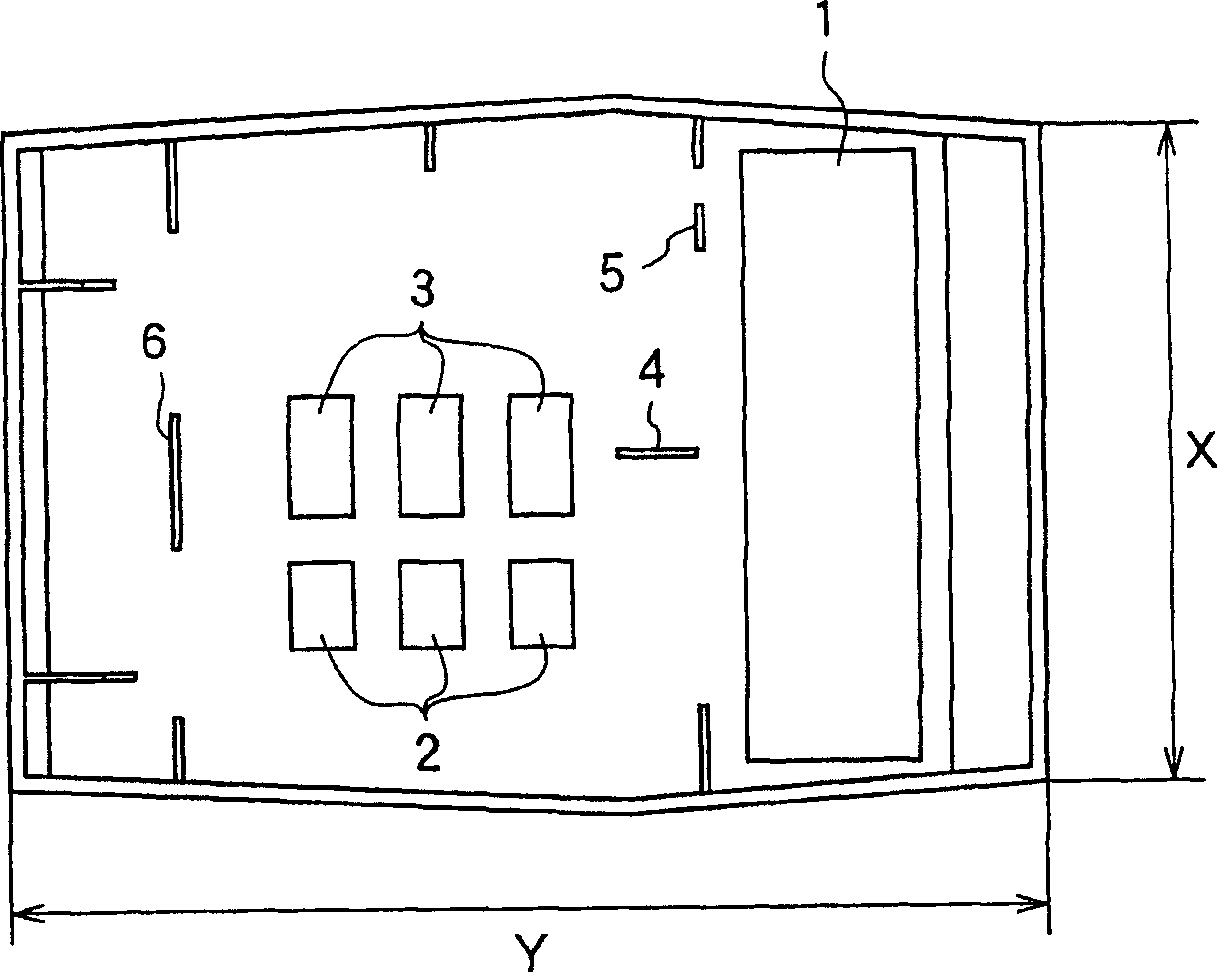

Injection-molded object

一种注射模塑、成型体的技术,应用在运输和包装、薄料处理等方向,能够解决机械强度下降、高阻燃性能、不能满足等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

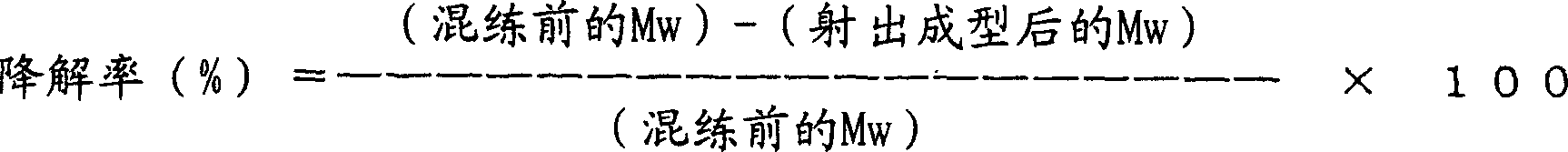

[0098] "Nature Works 6000D" (L-lactic acid / D-lactic acid = 95.8 / 4.2, weight average molecular weight 160,000) manufactured by Rikido Dou Co., Ltd. was used as the lactic acid resin, and "Pyrolaser-HG" manufactured by Ishizuka Glass Co., Ltd. was used. "(Aluminum hydroxide surface-treated with stearic acid, silane coupling agent and ammonium nitrate, w-Na 2O=0.05) as metal hydroxide. "Nature Works 6000D" and "Pyrolaser-HG" were dry-blended at a mass ratio of 100:25, and dried at 60°C for 12 hours with a vacuum dryer. The moisture content of this mixture was measured at 180° C. with a Karl Fischer moisture meter, and it was confirmed that the moisture content was 0.5% or less. Then, the mixture was blended at 180° C. using a 40 mmφ small co-direction twin-screw extruder manufactured by Mitsubishi Heavy Industries, Ltd. to form pellets. The obtained pellets were dried at 60° C. for 12 hours using a vacuum dryer. The moisture content was measured at 180° C. with a Karl Fischer ...

Embodiment 2

[0104] Except for the "BW103ST" manufactured by Nippon Light Metal Co., Ltd. (aluminum hydroxide surface-treated with a silane coupling agent, w-Na 2 O=0.05) As the metal hydroxide in Example 1, except that the mass ratio of "NatureWorks 6000D" and "BW103ST" was changed to 100:10, the same operation as in Example 1 was made into injection molding body.

[0105] The obtained injection molded article was evaluated in the same manner as in Example 1. The results are shown in Table 2.

Embodiment 3

[0107] Except changing the mass ratio of the compounding quantity of "Nature Works 6000D" and "BW103ST" in Example 2 to 100:25, it carried out similarly to Example 2, and produced the injection molding molding.

[0108] The obtained injection molded article was evaluated in the same manner as in Example 1. The results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

| linear shrinkage | aaaaa | aaaaa |

| linear shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com