Method for quick-speed preparing carbon/carbon composite material using heat gradient chemical gas phase infiltration

A chemical vapor infiltration and composite material technology, which is applied in the field of rapid preparation of composite materials, can solve problems such as difficult interpretation and calculation, atmospheric pressure exceeding positive pressure, danger, etc., and achieve the effects of reducing equipment investment, improving utilization rate, and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

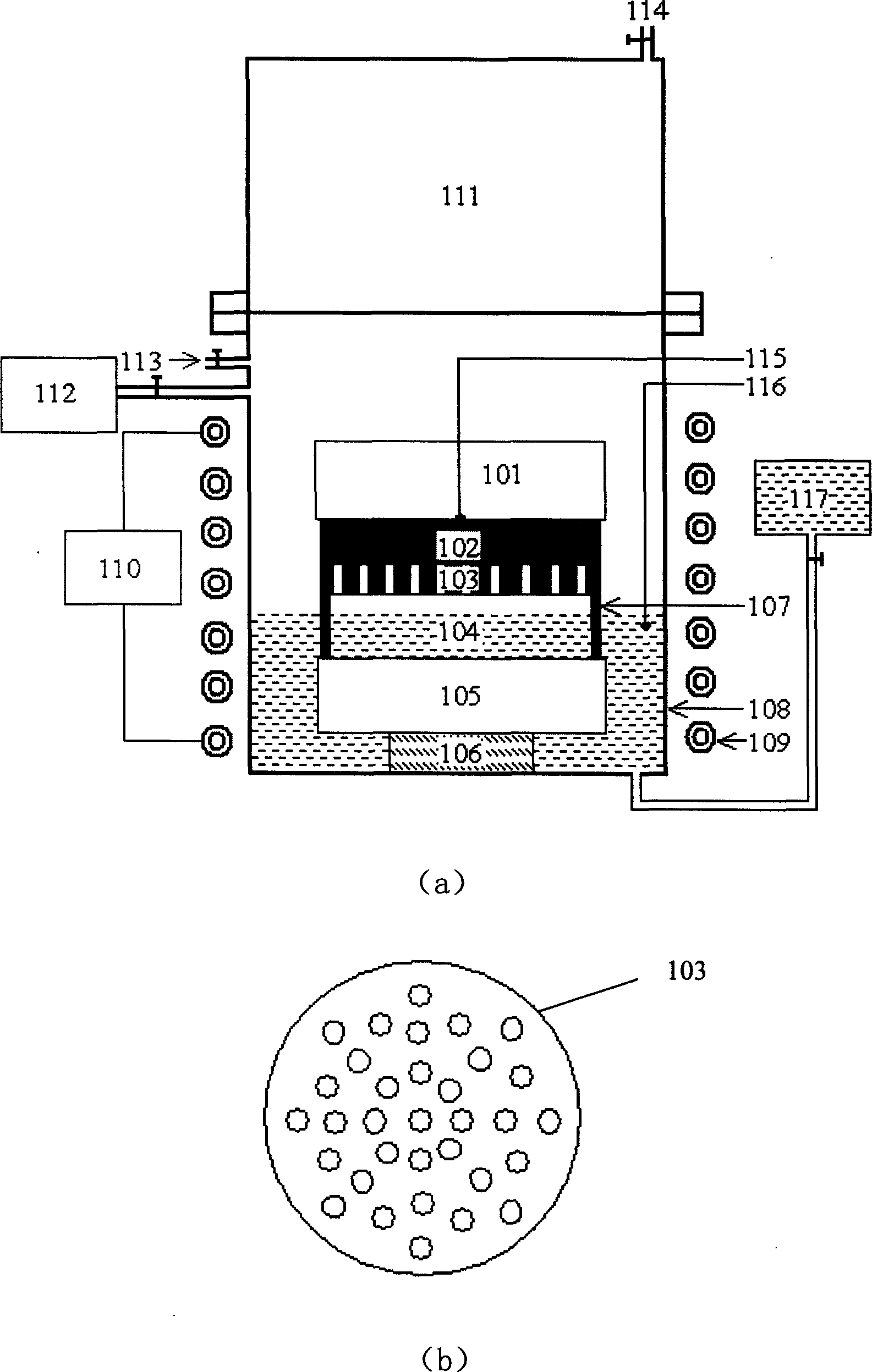

[0038] Embodiment 1: according to the technical scheme of the present invention, the carbon felt produced by Lanzhou Carbon Plant is used as a prefabricated body, and the carbon felt density is 0.1g / cm 3 , is composed of short fibers in any direction. Adopt the method of the present invention to prepare the concrete steps of the disc-shaped C / C composite material of single piece as follows:

[0039] (1) Prepare the prefabricated body and cut the carbon felt to Φ100×10mm 3 size of;

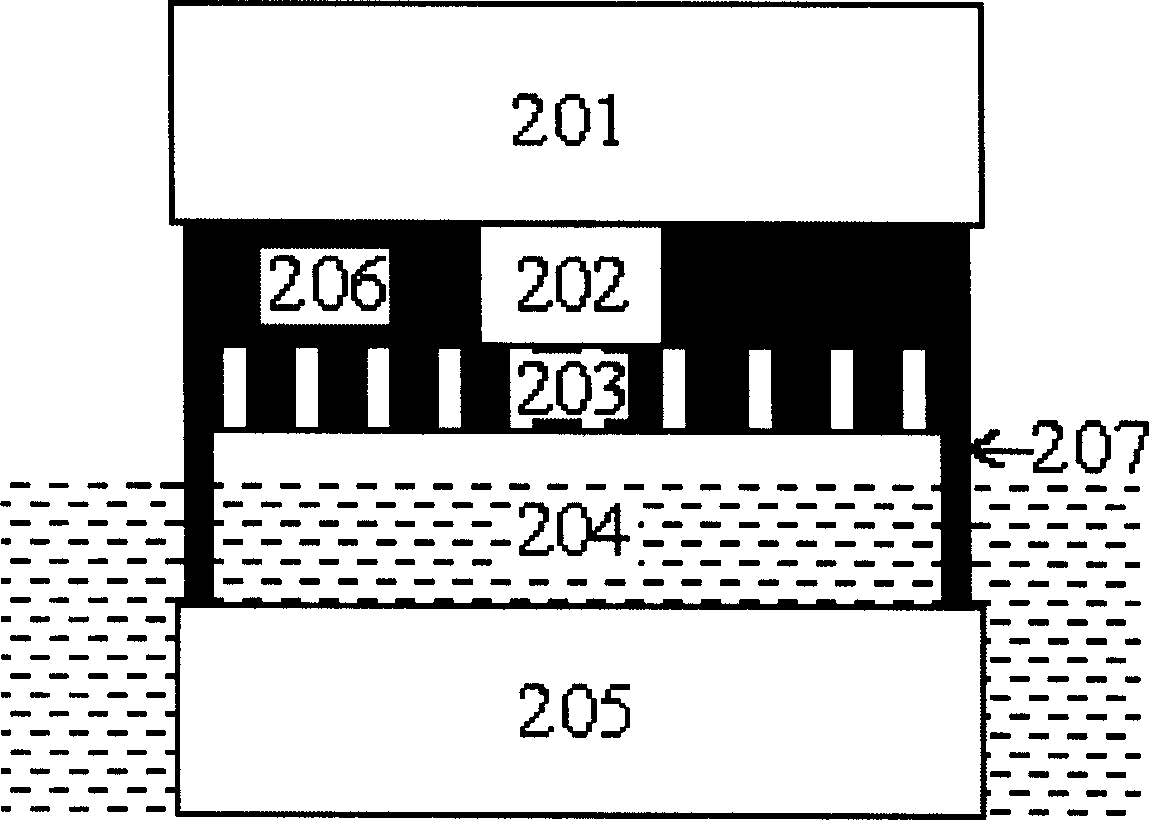

[0040] (2) Prepare the graphite heating element, process the upper and lower graphite heating elements to a diameter of Φ100mm, and a thickness of 130mm and 100mm respectively, and the prepared size is Φ100×15mm 3 The disc is used as a supporting plate, and several small holes (Φ10mm) are evenly drilled on it, and 4 pieces of size Φ15×100mm are prepared 3 Graphite support rods, prepare insulation pads (ordinary alumina bricks);

[0041] (3) Put the alumina brick, the lower graphite heating elem...

Embodiment 2

[0049] Embodiment 2: According to the technical scheme of the present invention, the needle-punched one-dimensional carbon cloth prefabricated body for preparing aircraft brake discs is adopted, and the density is ~0.5g / cm 3 . Adopt the method for the present invention to prepare the concrete steps of the annular C / C composite material of single piece as follows:

[0050] (1) Prepare the prefabricated body, and cut the needle-punched one-dimensional carbon cloth into a circular size with an outer diameter of Φ140mm, an inner diameter of Φ50mm, and a height of 20mm;

[0051] (2) Prepare the graphite heating element, process the upper and lower graphite heating elements to a diameter of Φ140, the thickness is 130mm and 100mm respectively, and the prepared size is Φ140×15mm 3 The disc is used as a supporting plate, and several small holes (Φ10mm) are evenly drilled on it, and 4 pieces of size Φ15×100mm are prepared 3 Graphite support rods, prepare insulation pads (ordinary alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com