Leak detector and process gas monitor

A detector and gas analyzer technology, used in the field of monitoring the status of flat panel display process systems, and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

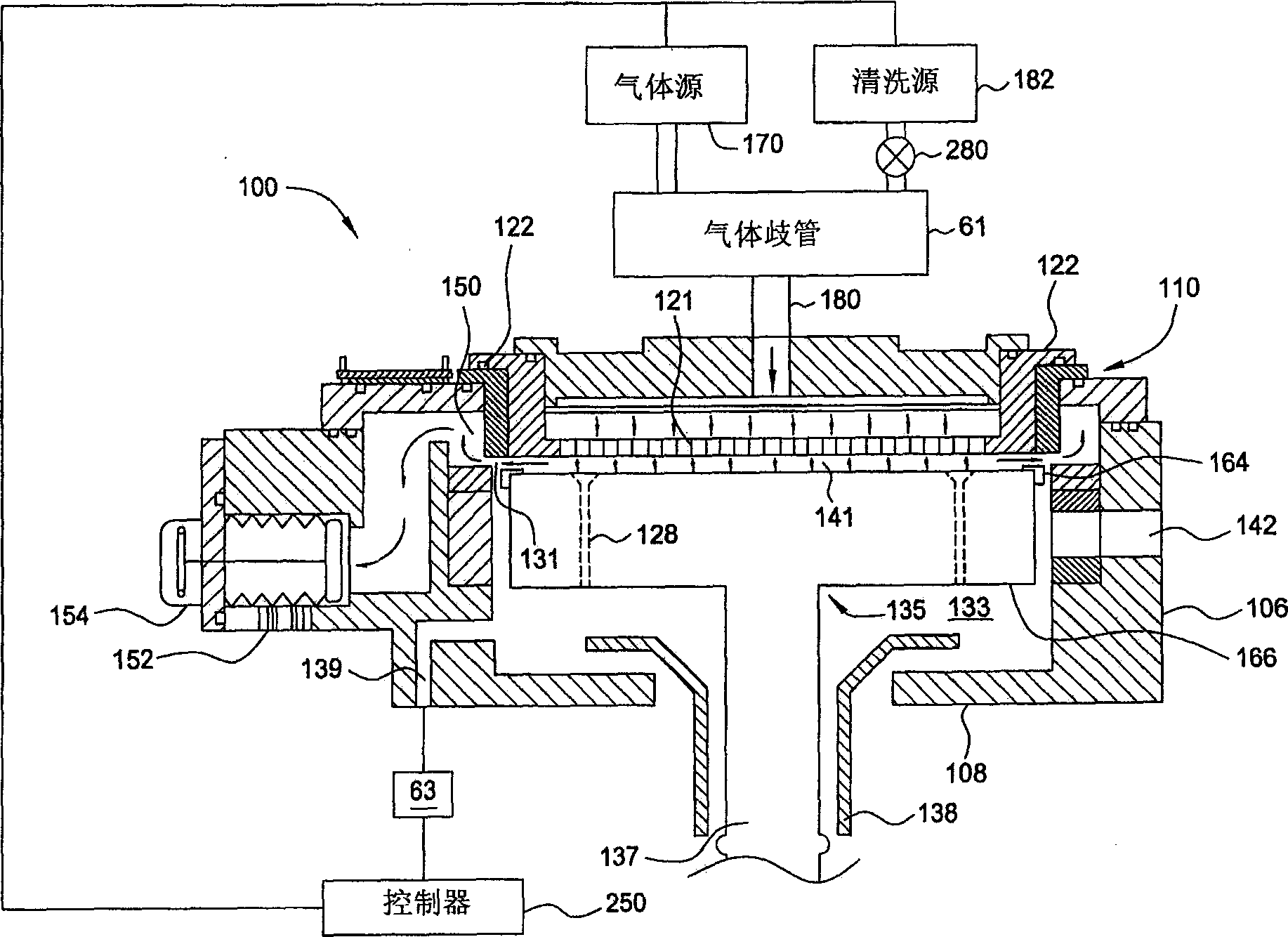

[0027] figure 1 A schematic cross-sectional view of one embodiment of a plasma-enhanced chemical vapor deposition system 100, commercially available from AKT, a division of Applied Materials, Inc., of Santa Clara, California, is shown. The system 100 includes a vacuum deposition reaction chamber 133 , the reaction chamber 133 has a chamber wall 106 and a bottom 108 , and the chamber wall 106 and the bottom 108 partially define a process region 141 . The cavity wall 106 and the bottom 108 are usually made of a single piece of aluminum or other process compatible materials. The chamber wall 106 has an opening 142 for transferring a flat panel display substrate into or out of the reaction chamber 133 . Specific examples of flat panel display substrates include glass substrates, polymer substrates, and other similar substrates. Although embodiments of the present invention are described with reference to a PECVD system, other embodiments of the present invention are also applica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com