Solid-state optical device

A technology of optical devices and solid-state components, which is applied in the fields of electrical solid-state devices, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problems of high viscosity and solid-state optical devices without sealing performance, and achieve excellent moisture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

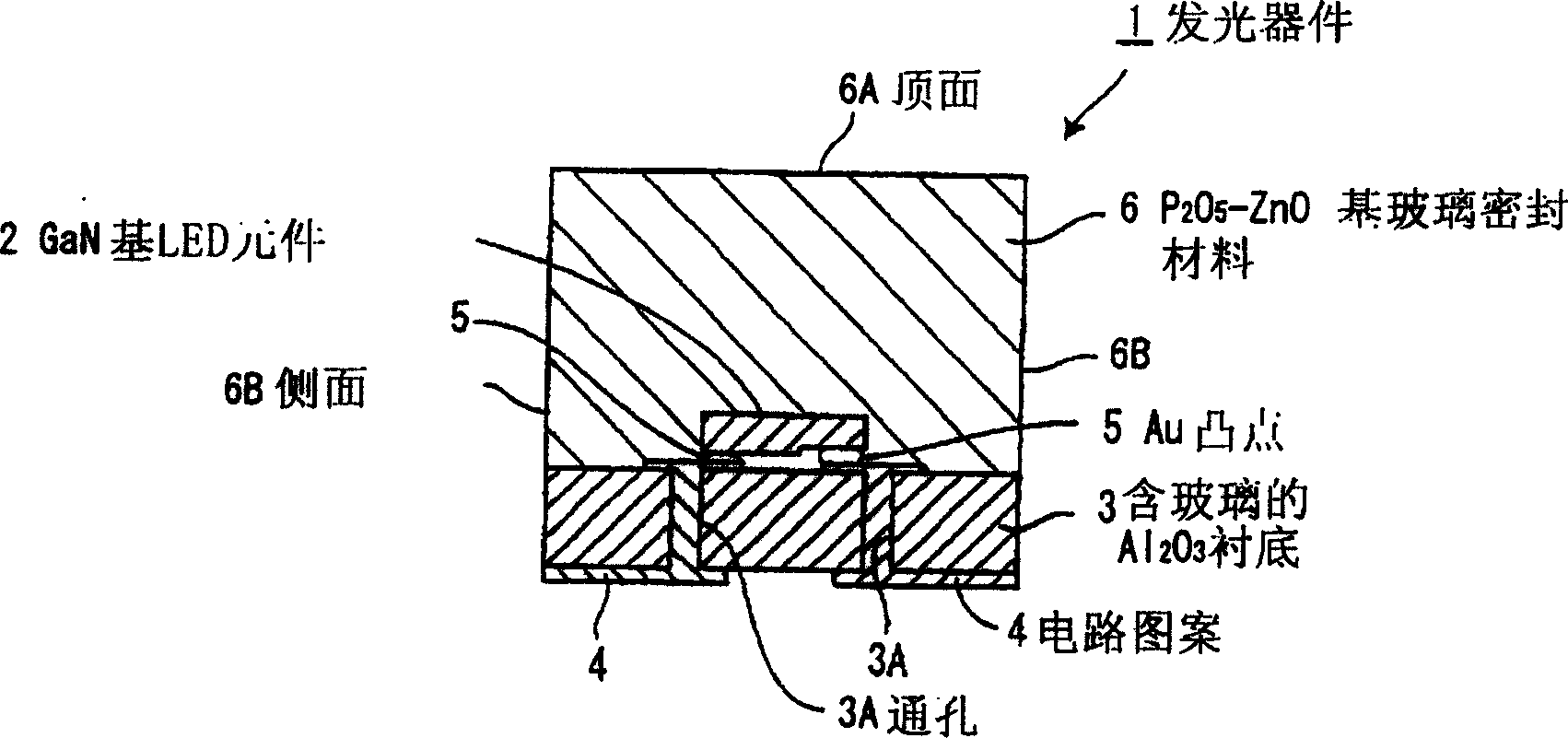

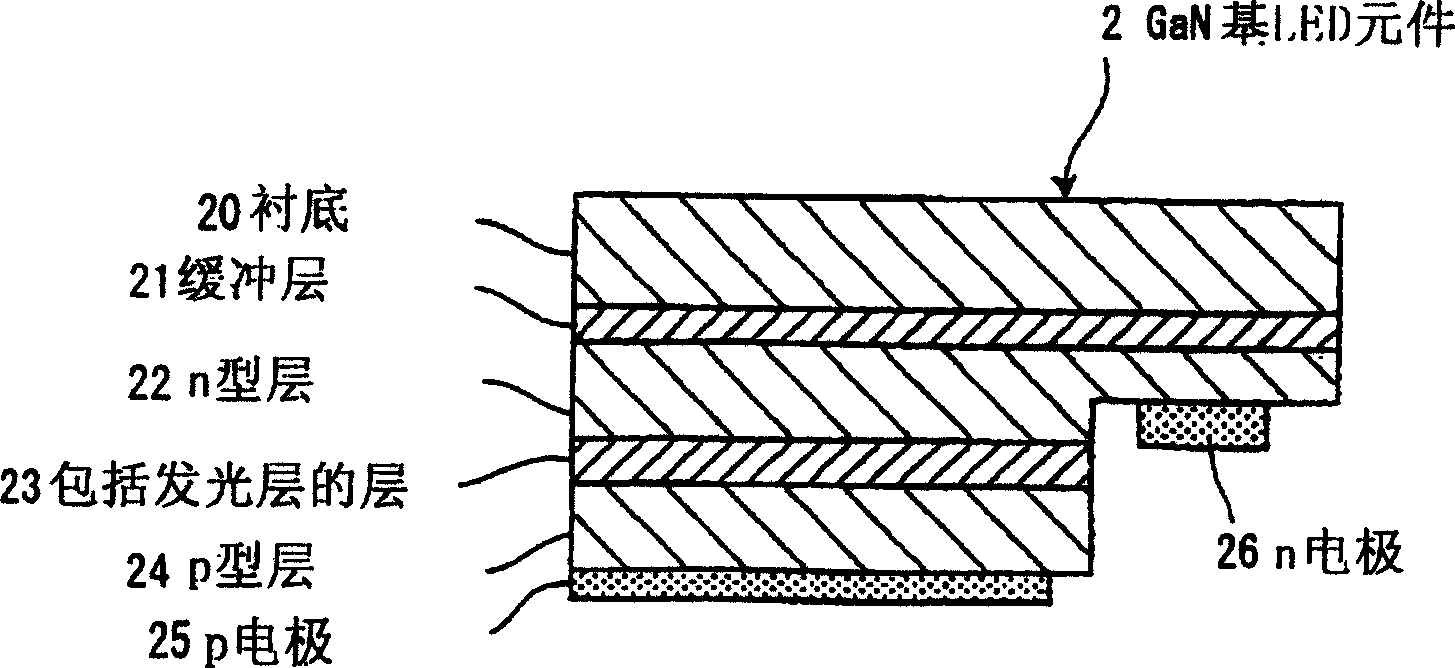

[0073] Figure 1A is a cross-sectional view showing a light-emitting device as a solid-state optical device in the first preferred embodiment of the present invention. Figure 1B is showing Figure 1A Side view of a GaN-based LED component.

[0074] [Configuration of Light-Emitting Device 1 ]

[0075] Figure 1A The light-emitting device 1 shown is composed as follows: a flip-chip type GaN-based LED element 2; 2 o 3 A substrate 3, which is an inorganic material substrate, on which a GaN-based LED element 2 is mounted; a circuit pattern 4, which is made of tungsten (W)-nickel (Ni)-gold (Au) and formed on a glass-containing Al 2 o 3 On the substrate 3; Au bump 5, which forms an electrical connection between the GaN-based LED element 2 and the circuit pattern 4; and a glass sealing material 6, which is P 2 o 5 -ZnO-Li 2 O-based transparent inorganic sealing material, and it is combined with glass-containing Al while sealing the GaN-based LED element 2 2 o 3 The substrate...

no. 2 approach

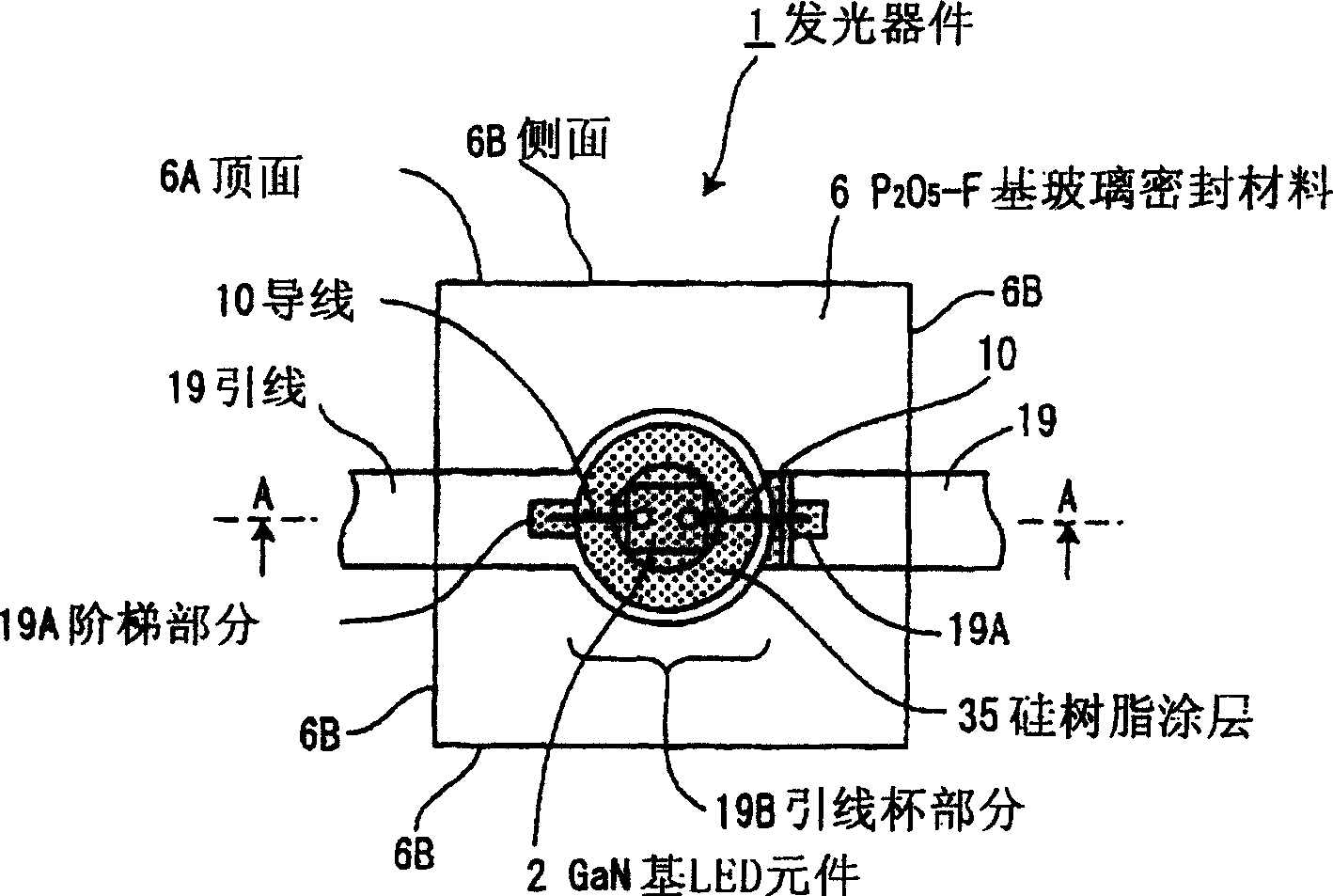

[0119] Figure 2A is a plan view showing a light emitting device as a solid-state optical device in the second preferred embodiment of the present invention; Figure 2B is along Figure 2A The cross-sectional view cut by the line A-A in; Figure 2C is showing Figure 2B Perspective view of the lower middle glass.

[0120] (Configuration of Light Emitting Device 1 )

[0121] The light emitting device 1 is composed as follows: a surface-mounted GaN-based LED element 2; a lead wire 19, as a power supply / recovery part, having a lead cover portion 19B on which the GaN-based LED element 2 is mounted; forming an electrical connection with the lead wire 19; and a silicone resin coating 35 covering the GaN-based LED element 2 and the wire 10 to protect them. GaN-based LED element 2 and leads 19 with P 2 o 5 -F-based glass sealing material 6 integrally sealed, the P 2 o 5 - The F-based glass sealing material 6 is composed of preformed upper glass 60A and lower glass 60B.

[01...

no. 3 approach

[0147] Figure 3A is a cross-sectional view showing a light-emitting device as a solid-state optical device in a third preferred embodiment of the present invention; Figure 3B is showing Figure 3A Side view of a GaN-based LED component.

[0148] (Configuration of Light Emitting Device 1 )

[0149] Figure 3A The light-emitting device 1 shown is composed of the following: a flip-chip GaN-based LED element 2 (the thermal expansion coefficient α is 5-7×10 -6 / °C); Al 2 o 3 A substrate 3, which is an inorganic material substrate, on which a GaN-based LED element 2 is mounted; a circuit pattern 4, which is made of tungsten (W)-nickel (Ni)-gold (Au), and formed on Al 2 o 3 On the substrate 3; Au bump 5, which forms an electrical connection between the GaN-based LED element 2 and the circuit pattern 4; and a glass sealing material 6, which is a transparent inorganic sealing material and bonded to Al 2 o 3 substrate 3 while sealing the GaN-based LED element 2 . In this emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com