High-accuracy self-adaptation driving power for ultrasonic transducer

A technology for driving power and transducers, which is applied to non-electric welding equipment, fluids using vibration, welding equipment, etc. It can solve problems such as peak point drift, inability to complete welding tasks, narrow bandwidth of ultrasonic transducers, etc., and achieve automatic Strong adaptability and good conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

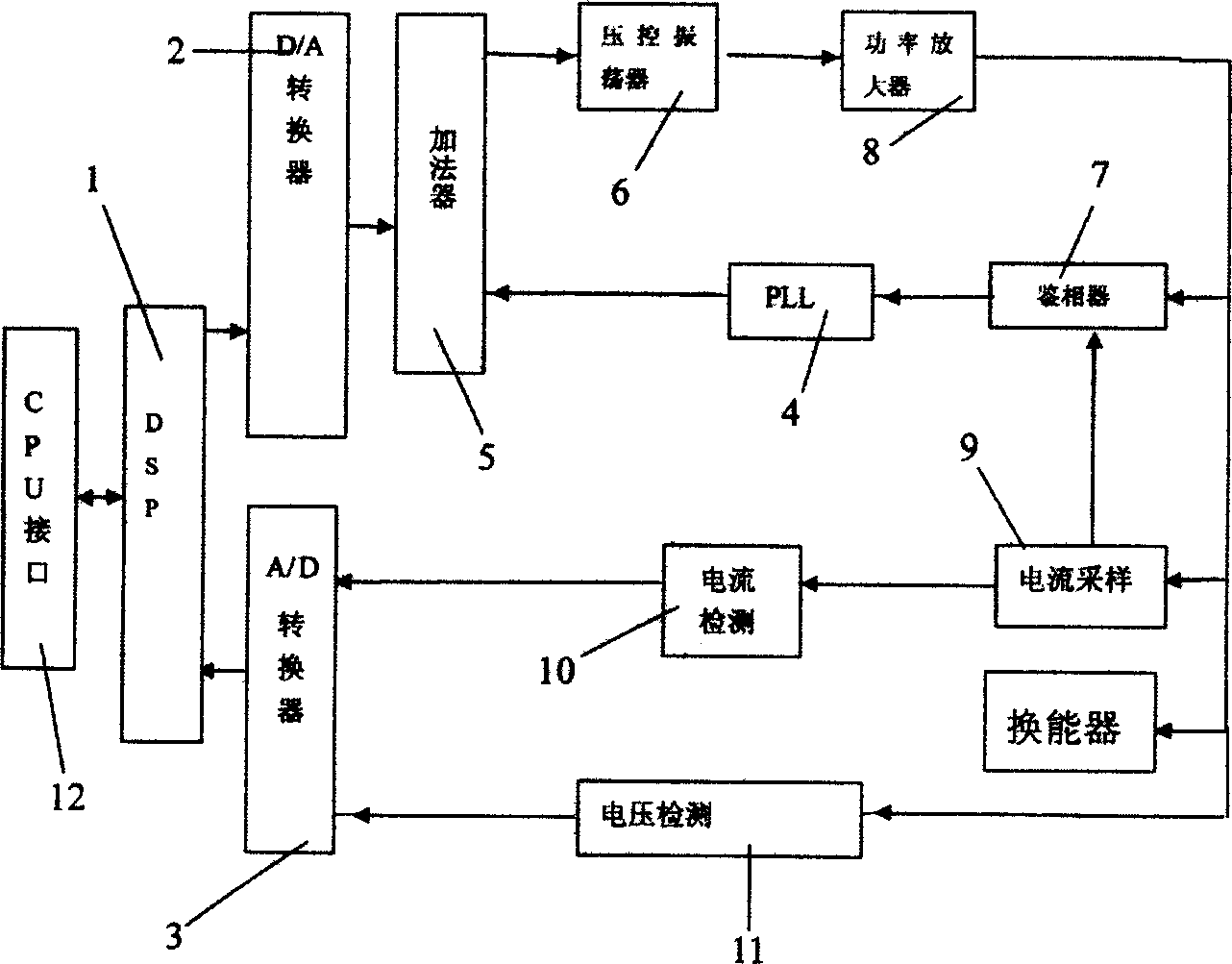

[0031] Examples see figure 1 , high-precision self-adaptive ultrasonic transducer driving power consists of a DSP-based processor circuit 1, a multi-channel high-speed D / A converter circuit 2, a multi-channel high-speed A / D converter circuit 3, a digital and analog compatible A phase-locked loop circuit 4, an adder circuit 5, a high-precision broadband voltage-controlled oscillator circuit 6, a phase detector circuit 7, a power amplifier circuit 8, an output current detection circuit 9, a micro-current detection circuit 10 , an output voltage detection circuit 11 and a high-speed serial communication interface circuit 12 and so on.

[0032] The high-precision self-adaptive ultrasonic transducer drive power supply of the present invention has a drive capability within a bandwidth of 100kHz (50kHz to 150kHz), and an output power of 5W.

[0033] Work process of the present invention is:

[0034] After power-on, the DSP processor circuit 1 initializes the original parameters of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com