Automatic injection powder mixing syringe

A powder injection and syringe technology, which is applied to the field of syringes for automatic mixing of powder injection and solvent, can solve the problems of medical staff's physical injury, waste, and wrong medication, and achieve the effects of reducing labor intensity, avoiding blood infection, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

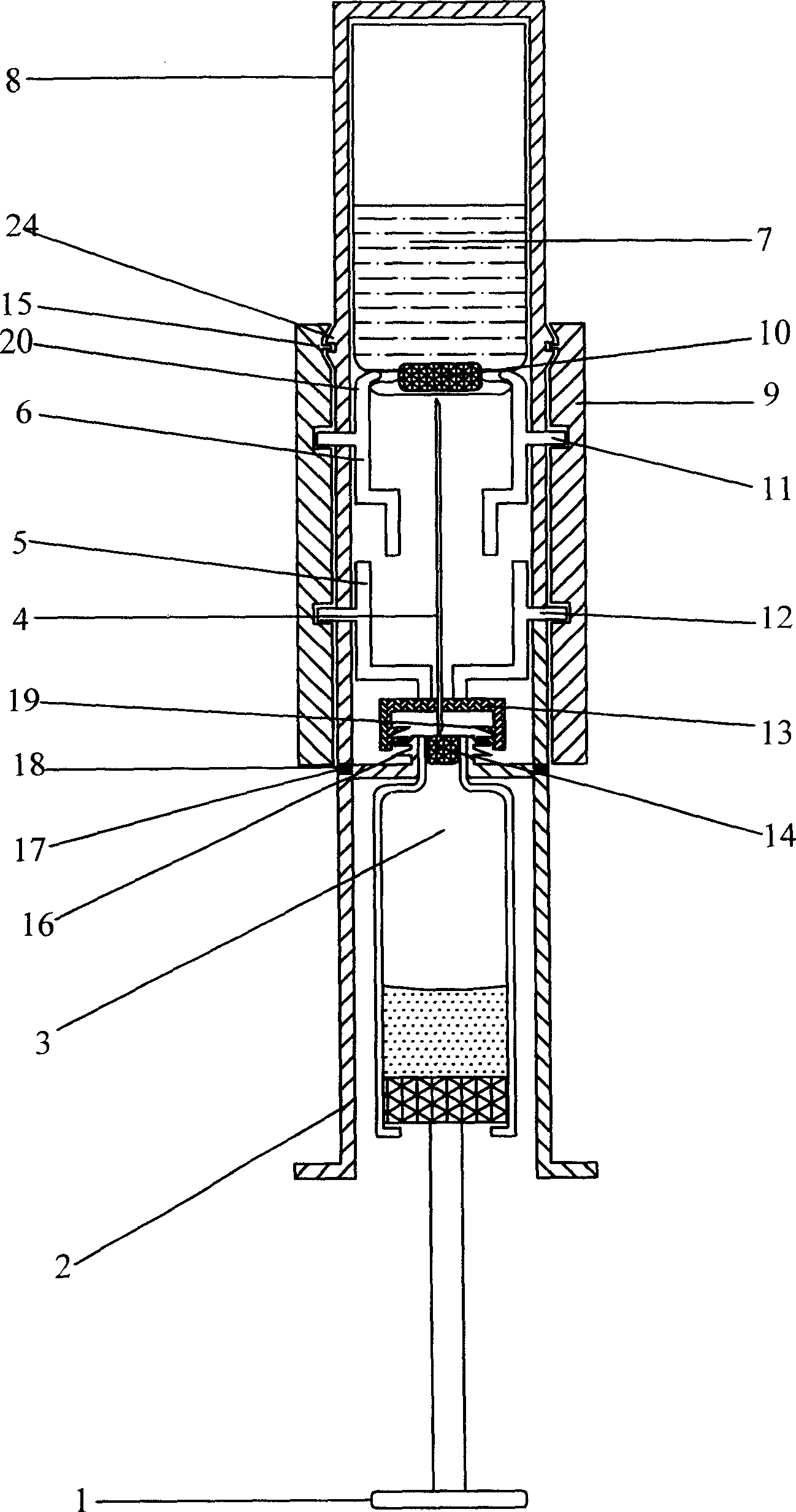

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

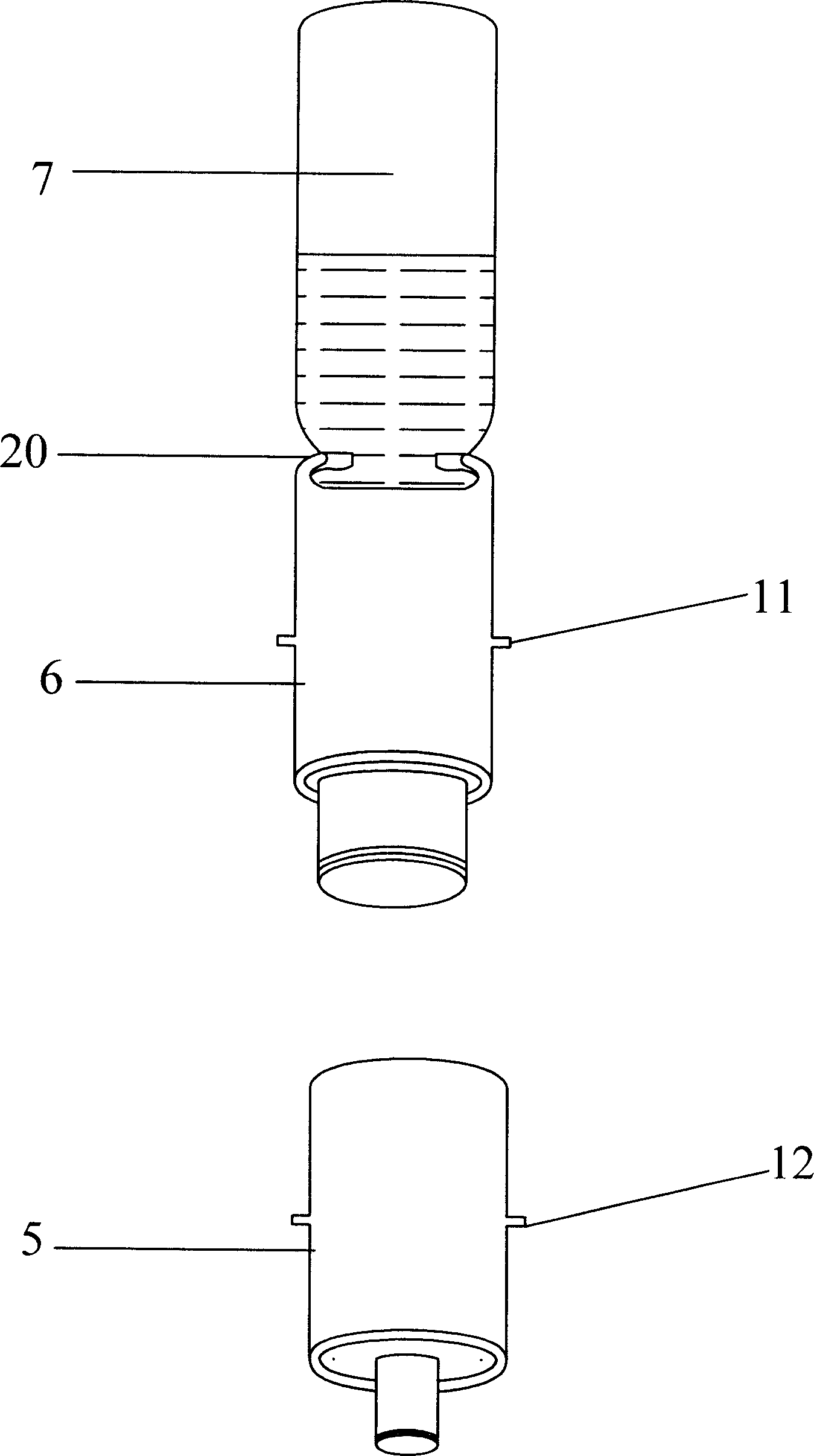

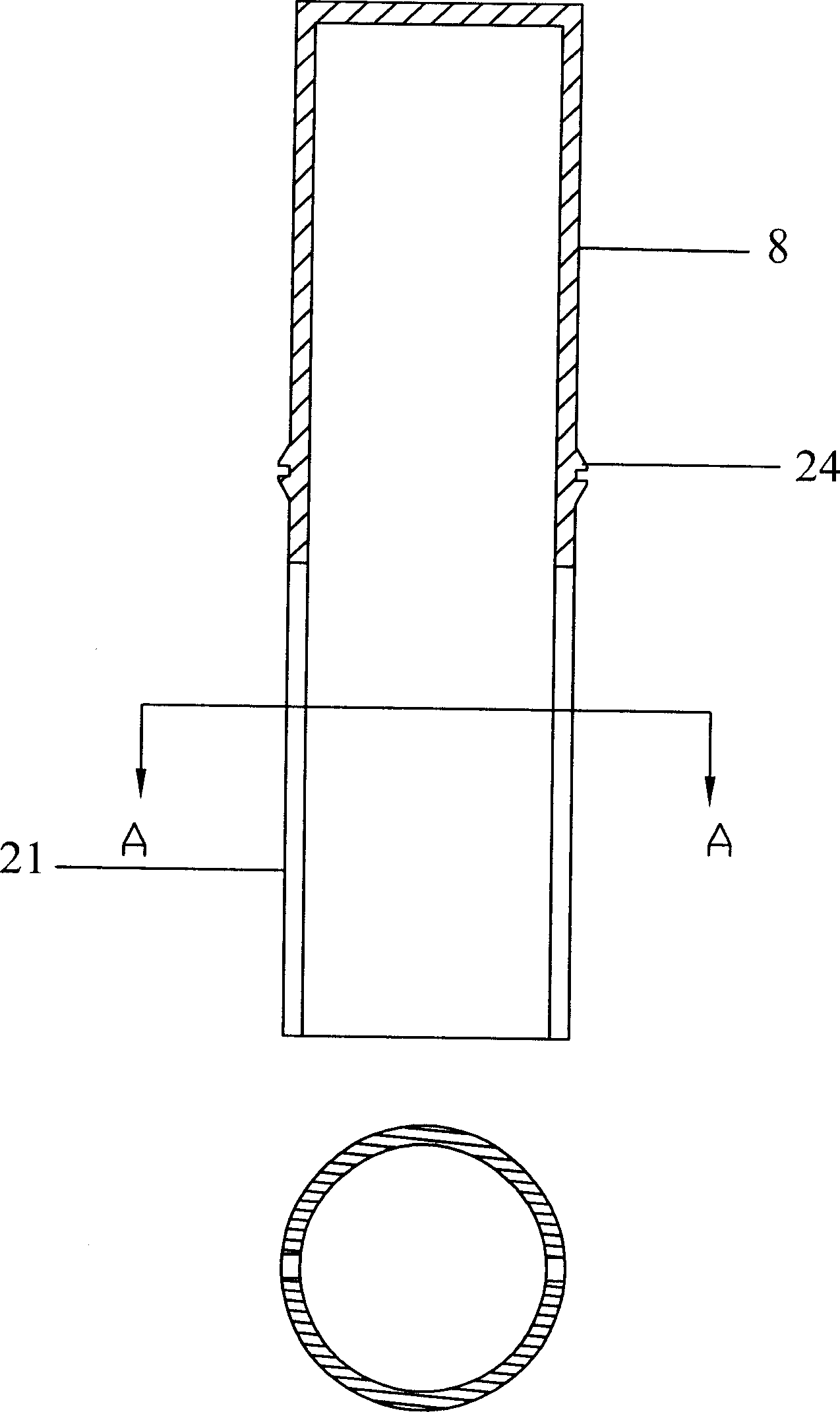

[0031] Such as figure 1 As shown, the present invention comprises solvent bottle 7, solute bottle 3, needle cap 13, solute bottle overcoat 2, solvent bottle overcoat 8, rotating overcoat 9, first gear push sleeve 5, second gear push sleeve 6 and push rod 1, described The solute bottle 3 is placed in the solute bottle jacket 2, the solvent bottle 7, the first gear push sleeve 5 and the second gear push sleeve 6 are placed in the solvent bottle jacket 8, and the described rotating jacket 9 is set in the solvent bottle jacket 8 Outside, the solute bottle jacket 2 is connected with the solvent bottle jacket 8 up and down. Wherein the solvent bottle 7 is a vial filled with internal pressure, and a rubber stopper 10 is installed at the bottleneck. The second gear push sleeve 6 is a cylindrical structure, and one end of the second gear push sleev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com