Countryside sewage treating method

A technology of rural sewage and sewage, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the lack of governance models and process technologies, immaturity, and lack of decentralized sewage treatment systems Targeted research and other issues to achieve the effect of simplified structure, small investment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Process parameters: the treatment object is domestic sewage, and the average influent concentration is COD Cr =258.69mg / L, BOD 5 =110mg / L, TN=25.07mg / L, TP=3.09mg / L, NH 4 - N = 20.93 mg / L.

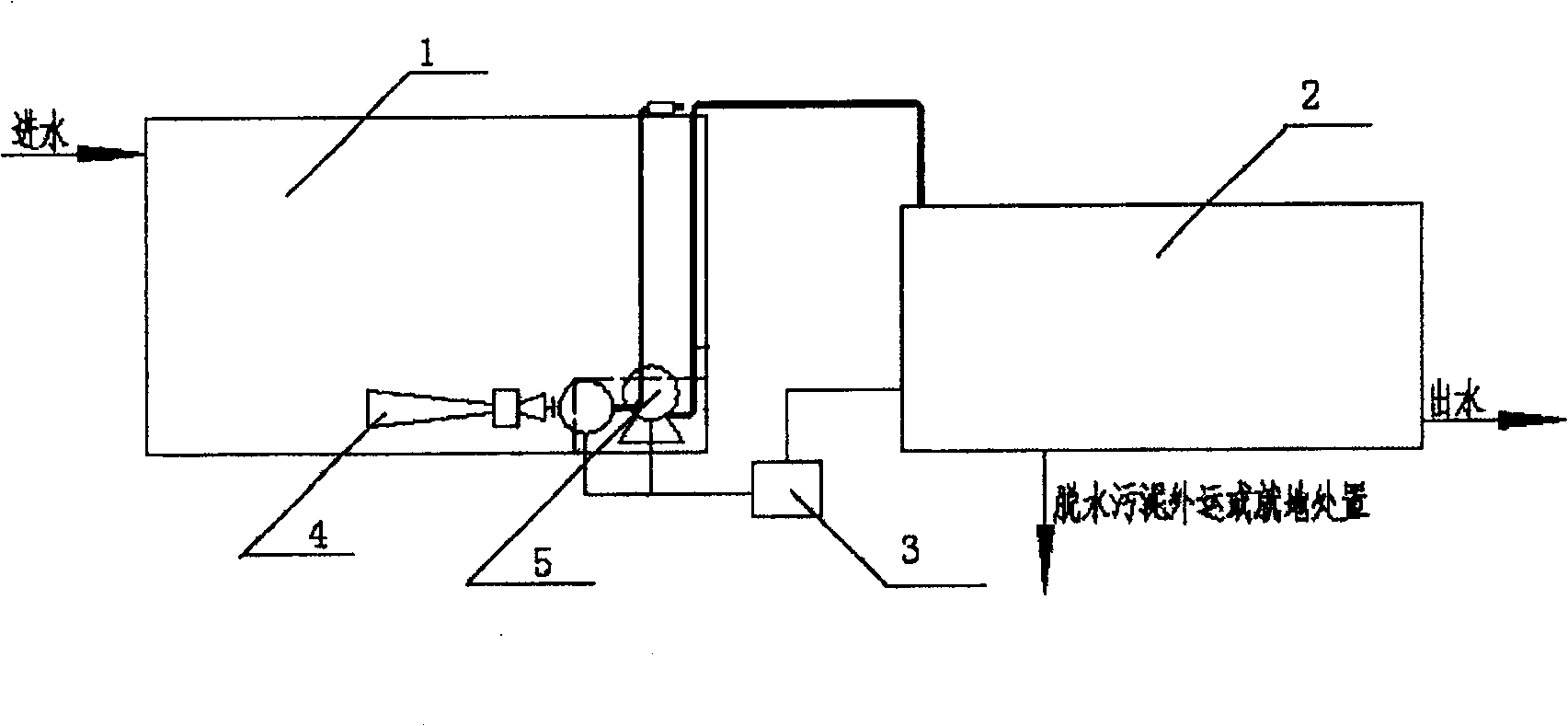

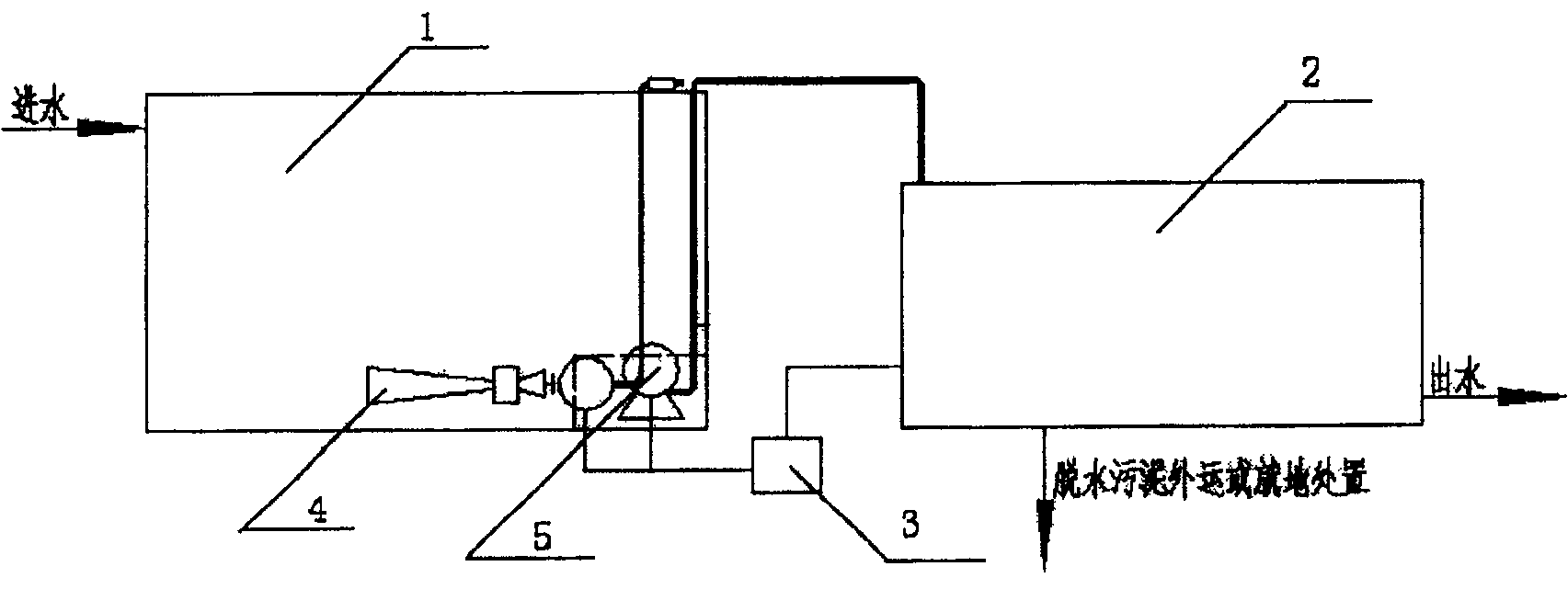

[0025] The treatment process is as follows: sewage enters the grit chamber for sedimentation and then enters the JACR reaction tank 1, controls the aeration of the jet aerator 4 through the electric control cabinet 3, and discharges the water through the submersible sewage pump 5. The operation cycle is 4 days, and the processing capacity is 4m 3 / d, the aeration cycle is 15 minutes every 2 hours, the sludge concentration MLSS value varies with the water level in the pond, and is 2540-5250mg / L, and the air-water ratio is 15:1.

[0026] Treatment effect: After the JACR process treatment, the average concentration of the effluent of each index is: COD Cr =52.25mg / L, BOD 5 =12mg / L, TN=2.81mg / L, TP=0.96mg / L, NH 4 -N=0.62mg / L, SS=12.8mg / L, the effluent water quality reaches the fir...

Embodiment 2

[0029] Process parameters: engineering design processing capacity is 30m 3 / d, the operation period is 6 days, the aeration period is 15 minutes every 2 hours, and the air-water ratio is 15:1. The average influent concentration is COD Cr =318.82mg / L, BOD 5 =135mg / L, TN=33.47mg / L, TP=7.54mg / L, NH 4 -N=26.29 mg / L, SS=134.5 mg / L.

[0030] The treatment process is as follows: sewage enters the grit chamber for sedimentation and then enters the JACR reaction tank 1, controls the aeration of the jet aerator 4 through the electric control cabinet 3, and discharges the water through the submersible sewage pump 5.

[0031] Treatment effect: After the JACR process treatment, the average concentration of the effluent of each index is: COD Cr =54.42mg / L, BOD 5 =10mg / L, TN=5.41mg / L, TP=0.87mg / L, NH 4 -N=3.14mg / L, SS=15mg / L, both of which have reached the first-class B discharge standard in the national urban sewage treatment plant pollutant discharge standard (GB18918-2002).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com