Method for forming superhydrophobic surface of solid material

A technology of super-hydrophobic surface and solid material, which is applied in the field of formation of super-hydrophobic surface of solid material, can solve the problems of complex process and equipment requirements, degraded super-hydrophobic performance, and insufficiently low surface energy, etc., and achieves easy operation, low cost, good structural quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: Make a micro-nano structure negative mold soft stamp with a super-hydrophobic surface:

[0031] Mix the prepolymer and crosslinking agent of polydimethylsiloxane (PDMS, purchased from Dow Corning Company) uniformly in a mass ratio of 10:1, pour it on the clean and flat lotus leaf surface, and let it stand for 20 minutes. It becomes an elastomer after heating and curing. The reaction temperature is 40°C and the reaction time is 3 hours; After curing, the PDMS soft stamp can be obtained by peeling off.

[0032] Step 2: Fabricate superhydrophobic surfaces on solid materials:

[0033] A bisphenol A type epoxy resin was dissolved in tetrahydrofuran (THF) to prepare a solution at a concentration of 10 mg / ml as the polymer-containing "ink". Dip the "ink" with the PDMS soft stamp prepared above, and stamp it on the surface of the glass substrate; or drop a small amount of the above "ink" on the surface of the glass substrate, and then stamp it on the "ink" with the PD...

Embodiment 2

[0035] Mix the prepolymer of polydimethylsiloxane and the crosslinking agent evenly according to the mass ratio of 5:1, pour it on the clean and flat surface of the lotus leaf, let it stand for 10 minutes, and become an elastomer after heating and curing. 50°C, the reaction time is 3 hours; or after pouring, let it stand at room temperature for 10 hours to let it solidify naturally. After curing, the PDMS soft stamp was obtained by peeling off.

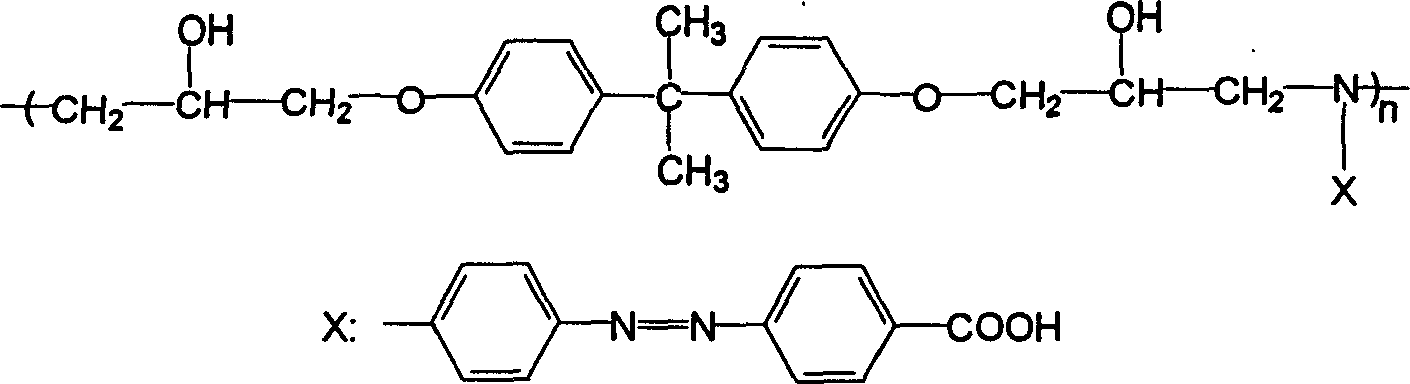

[0036] A kind of bisphenol A type epoxy resin derivative, epoxy resin-based azo polymer (see below for structural formula) is dissolved in tetrahydrofuran (THF) to make a solution, the concentration is 2 mg / ml, as the " ink". Dip the "ink" with the PDMS soft stamp prepared above, and stamp it on the surface of the glass substrate; or drop a small amount of the above "ink" on the surface of the glass substrate, and then stamp it on the "ink" with the PDMS soft stamp. Keep the soft stamp in contact with the material surface for second...

Embodiment 3

[0040] Mix the prepolymer of polydimethylsiloxane and the crosslinking agent evenly according to the mass ratio of 7:1, pour it on the clean and flat lotus leaf surface, let it stand for 20 minutes, and become an elastomer after heating and curing. 35°C, the reaction time is 7 hours; or after pouring, let it stand at room temperature for 10 hours to let it solidify naturally. After curing, the PDMS soft stamp was obtained by peeling off.

[0041] Polyamide epoxy resin was dissolved in tetrahydrofuran (THF) to prepare a solution at a concentration of 9 mg / ml as the polymer-containing "ink". Use the PDMS soft stamp prepared above to dip the "ink" and imprint it on the surface of the quartz substrate; or drop a small amount of the above "ink" on the surface of the quartz substrate, and then use the PDMS soft stamp to imprint on the "ink". Keep the soft stamp in contact with the material surface for seconds to minutes. After the solvent is completely evaporated, the soft seal is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com