Method for preparing intelligent photomasking film material

A thin film material, light shielding technology, applied in optics, nonlinear optics, instruments, etc., can solve the problem of not realizing energy saving, and achieve the effect of energy saving and indoor temperature improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

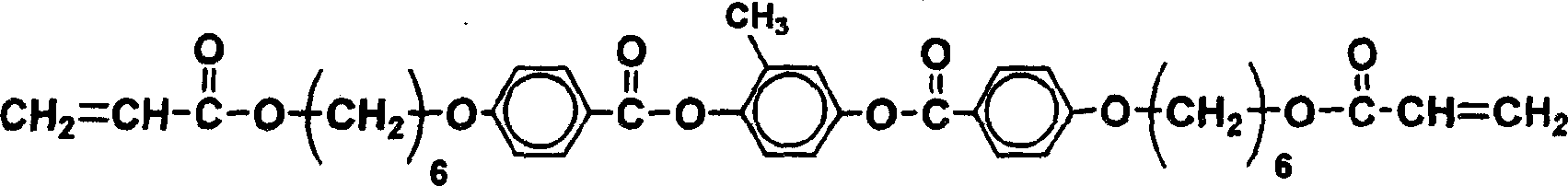

[0018] The liquid crystal containing smectic phase to chiral nematic phase transition selects trade names S6 (Merck co., Ltd.), SLC-1717 (Shijiazhuang Yongsheng Huaqing Liquid Crystal Co., Ltd.) and chiral additive CB15 (Merck co., Ltd.) Preparation, three ratios are 80%: 15%: 5%, the polymerizable monomer is synthesized by the laboratory, the molecular formula is as follows, the photoinitiator is selected from 1-hydroxycyclohexyl phenyl ketone, trade name 184 (Jingjiang Hongtai Chemical Industry Co., Ltd. Co., Ltd.), the quality of the polymerizable monomer is 5% of the total mass of the mixed liquid crystal, and the quality of the photoinitiator is 1% of the monomer quality. The desired mixed solution can be obtained after the above components are mixed evenly.

[0019] Polymerizable monomer molecular formula:

[0020]

[0021] The mixed solution is injected into a liquid crystal cell made of ITO glass without any surface treatment. The thickness of the liquid crystal ce...

example 2

[0023] The liquid crystal adopts the mixed liquid crystal prepared in Example 1, without adding monomer and photoinitiator.

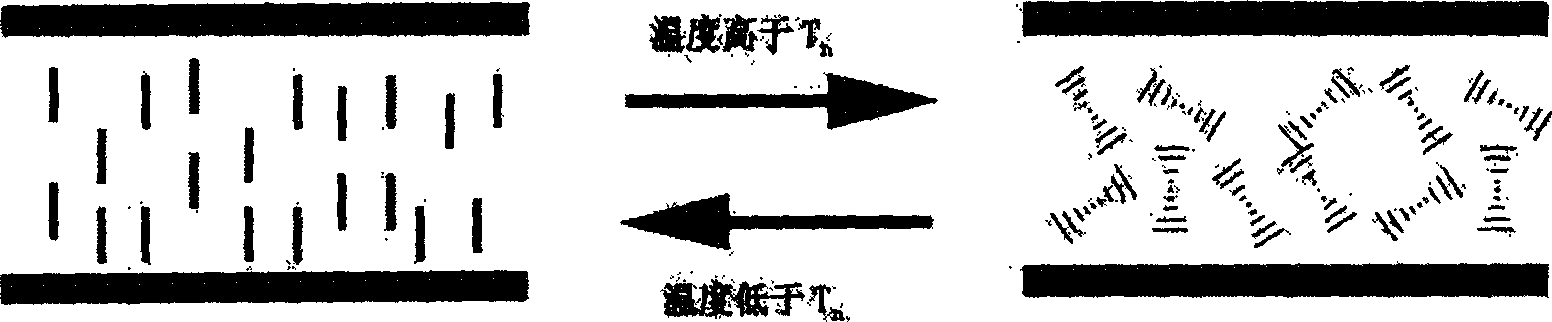

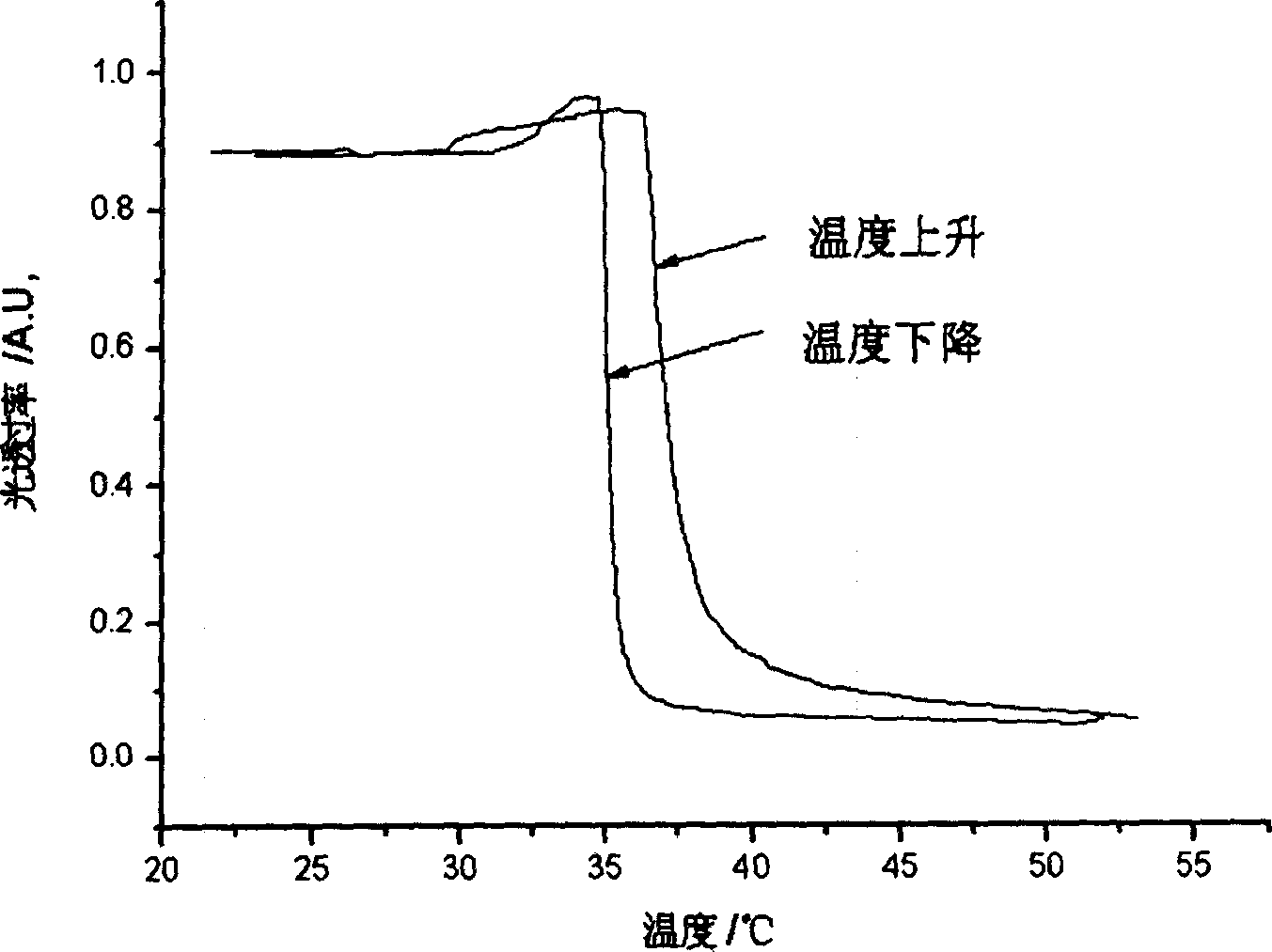

[0024] The substrate is subjected to surface vertical alignment treatment, and the surface alignment agent used is N, N-dimethyl-N-octadecyl-3-aminipropyltrimethoxysilyl chloride. The smectic phase liquid crystal molecules will be arranged perpendicular to the substrate under the influence of the surface alignment agent, and the film is in a light transparent state; after cooling from the high-temperature chiral nematic phase to the nematic phase, it will also return to the vertical alignment, and then turn from a non-transparent state to a nematic state. transparent state. The transition temperature was 36.3°C.

example 3

[0026] Use a side chain liquid crystal polymer and SLC-1717 to prepare the required liquid crystal with smectic phase to nematic phase transition, add CB15 to it, and the molecules of the side chain liquid crystal polymer are shown below, the mass of the three components The ratio is 6%:90%:4%. Add 1% polymerizable monomer (same as Example 1) and 0.01% photoinitiator 184 to the mixed liquid crystal, and stir evenly. Carry out surface vertical alignment treatment (same as Example 2) to the liquid crystal cell, inject the mixture in the liquid crystal cell, the mesogen of the side chain liquid crystal polymer is subjected to the influence of the surface vertical alignment agent to align the surface of the vertical substrate, and then place the liquid crystal cell in the ultraviolet When irradiated with light, the polymerizable monomers in it will undergo a polymerization reaction, and the vertical alignment of the mesogens will be maintained. The phase transition temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com