Polyhydrocarbon silicon-oxygen plastic pipe

A technology for plastic hoses and hoses, which is applied in the direction of hoses, pipes, pipes/pipe joints/fittings, etc. It can solve the problems of hoses turning yellow, difficult to see inside, and rot, and achieve good sliding properties, easy sliding, The effect of preventing discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

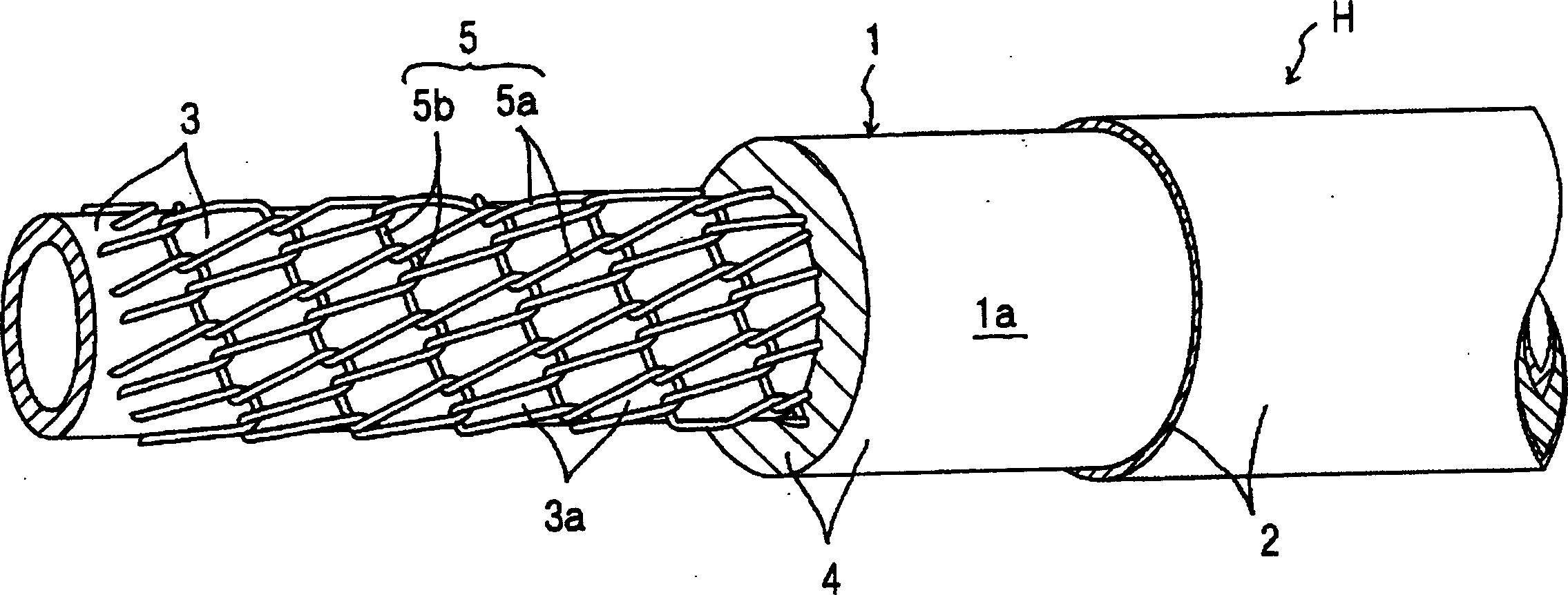

[0038] In this Embodiment 1, as figure 1 As shown, the above-mentioned hose body 1 is a polyhydrocarbon silicone reinforced plastic hose with good pressure resistance. The main component is a transparent or slightly white turbid see-through translucent inner layer 3 and an outer layer formed of silicone rubber. The layer 4 and the reinforcement wire 5 wound in layers between the two layers are laminated.

[0039] In the case of the illustrated example, the above-mentioned reinforcing wire 5 is, for example, reinforcing yarn or reinforcing fiber such as polyester or amide fiber or aramid fiber. The outer peripheral surface 3a is braided into a cylindrical shape, and the outer layer 4 is extruded on the outside of the reinforcing wire 5, and the above-mentioned parts are formed into a whole by lamination.

[0040] In addition, as a method of knitting the above-mentioned reinforcing wire 5, knitting is performed as shown in the figure, and longitudinal knits 5a... Weave 5b... a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap