Boiling cavity type radiator

A heat dissipation device and boiling chamber technology, applied in cooling/ventilation/heating transformation, instruments, electrical digital data processing, etc., can solve the problems of heating element 20 temperature rise, boiling fluid oscillating contact, and inability to ensure heat transfer function, etc., to achieve Easy processing, fewer components, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

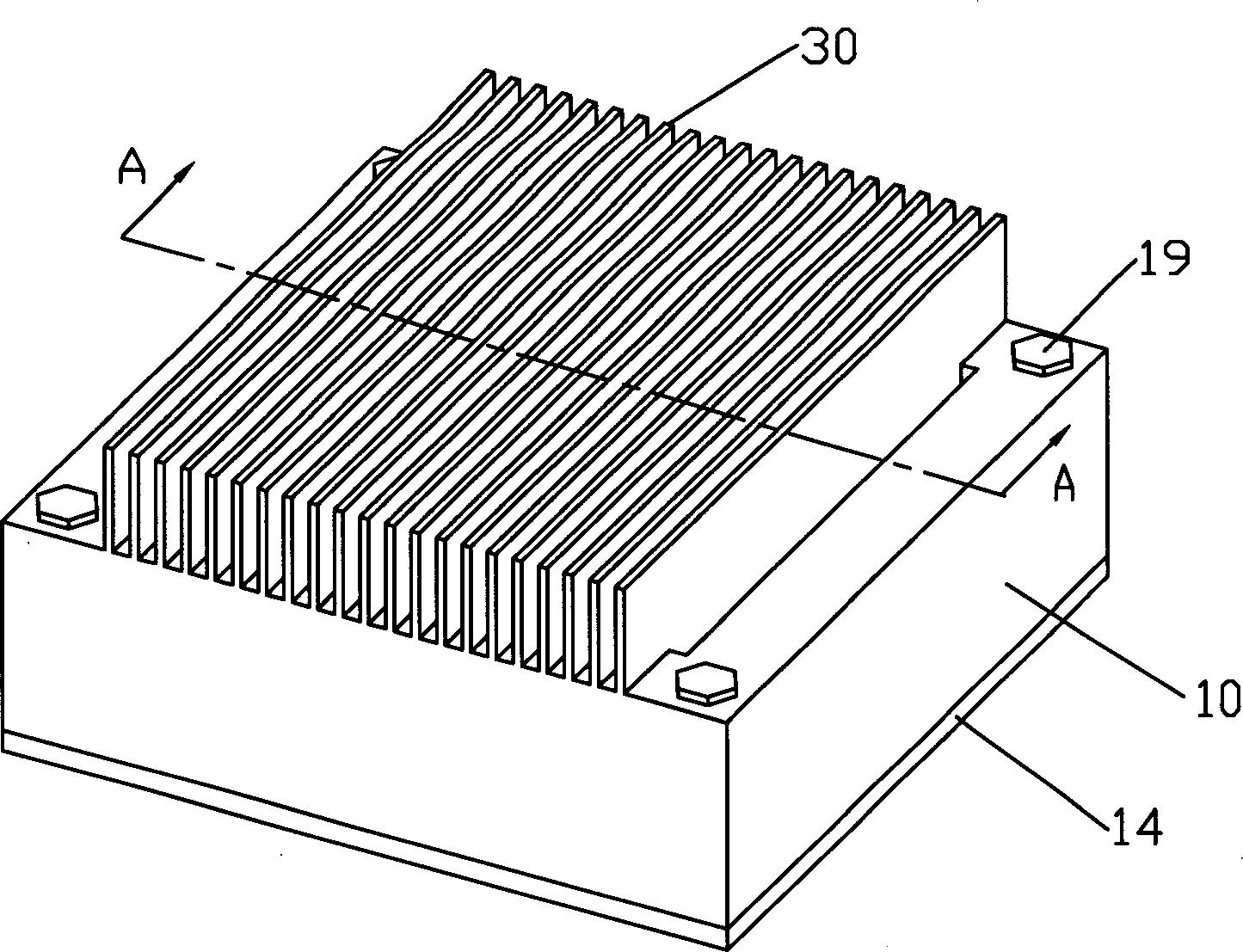

[0044] see Figure 3 to Figure 16 As shown, the boiling chamber heat sink of the present invention is used to be installed on a heating element 20 such as a central processing unit to dissipate heat.

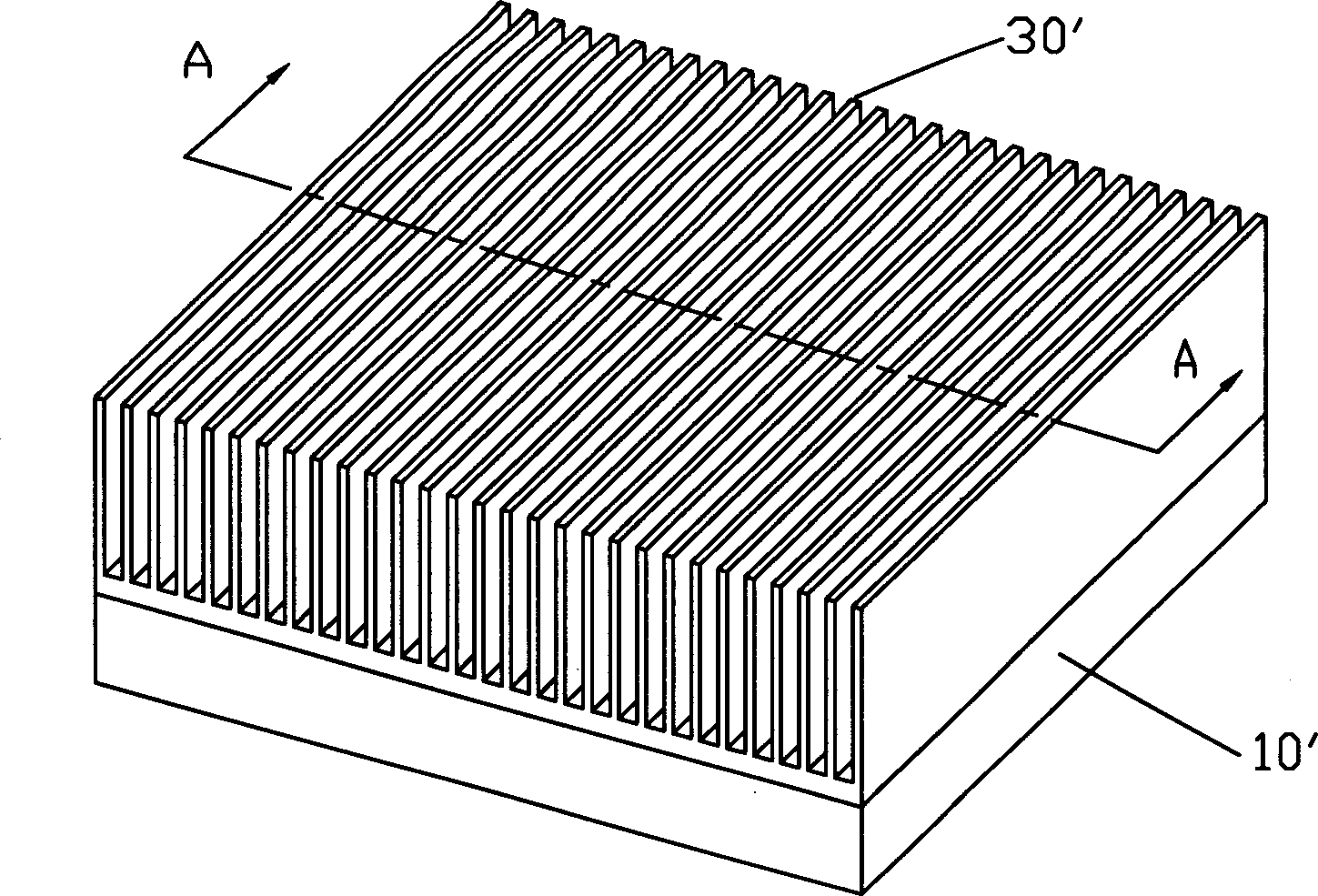

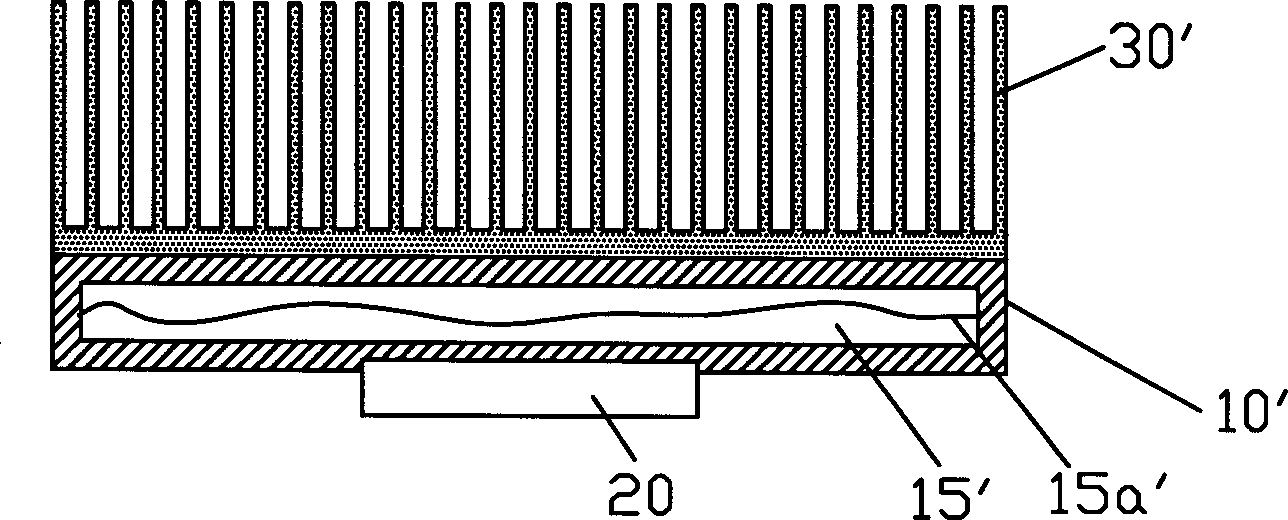

[0045] image 3 It is a three-dimensional schematic diagram of the first embodiment of the boiling chamber heat sink of the present invention; Figure 4 for the reason image 3 In the cross-sectional view of the A-A section, the device includes a sealed cavity 10 and a heat dissipation fin 30 that is in close contact with the top of the cavity 10, and the bottom of the cavity 10 is in close contact with the heating element 20; wherein the cavity 10 is used for Accommodating the working fluid 15 that absorbs heat from the heating element 20 and produces a phase change, it is composed of a top cover 11, a side frame 12, and a heat-absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com