Biological emulsifier for anti-freezing fermentation of frozen dough

A biological emulsifier and frozen dough technology, applied in the field of food additives, can solve the problems of destroying the gluten network structure, hidden safety hazards, and destroying cell tissue structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] In the embodiment of the present invention, the bioemulsifier component proportioning for frozen dough antifreeze fermentation is by weight percentage:

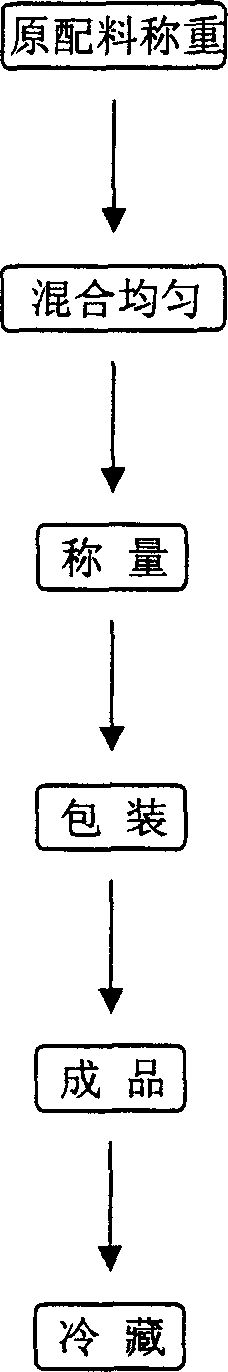

[0014] In the embodiment of the present invention, take lipase: 50%, pentosanase: 30%, guar gum: 0.3%, calcium stearoyl lactylate: 19.7%; the above components are accurately weighed according to the proportioning ratio , placed in a blender and mixed evenly, the speed of the blender: 110-120 rpm, stirring time: 5-10 minutes. The stirred mixture is weighed according to the packaging standard, and it is finished product after packaging, and finally refrigerated for future use.

Embodiment 2

[0016] In the embodiment of the present invention, the bioemulsifier component proportioning for frozen dough antifreeze fermentation is by weight percentage:

[0017] In the embodiment of the present invention, take lipase: 55%, pentosanase: 25%, carboxymethyl cellulose: 0.1%, calcium stearoyl lactylate: 19.9%; adopt the process step in the embodiment one Also made up to standard biological emulsifier.

Embodiment 3

[0019] In the embodiment of the present invention, the bioemulsifier component proportioning for frozen dough antifreeze fermentation is by weight percentage:

[0020] Take lipase in the embodiment of the present invention: 53%, pentosanase: 27.5%, locust bean gum: 0.2%, calcium stearoyl lactylate: 19.3%; adopt the process step in embodiment one, two Also made up to standard biological emulsifier.

[0021] The raw materials adopted in the present invention are purchased from the market, and what use is conventional equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com