Solid lubricating flexible coating of high speed steel fool and its preparation method

A technology of solid lubrication and solid lubricants, which is applied in the direction of lubricating compositions, petroleum industry, base materials, etc., can solve the problems of waste liquid discharge environmental pollution, health hazards of operators, high cost of cutting fluid waste liquid treatment, etc., and achieve cutting Good effect, good anti-friction effect, effect of improving anti-friction effect

Inactive Publication Date: 2006-06-14

NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

View PDF0 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, it is found that the use of cutting fluid will pose a hazard to the health of operators, and the discharge of waste liquid will also cause serious pollution to the environment, and the cost of cutting fluid waste treatment is very high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0017] Example 1, glycerin and water: 85%, MoS 2 : 7%, Graphite: 4%, Al 2 o 3 : 4%.

Embodiment 2

[0018] Example 2, glycerin and water: 80%, MoS 2 : 10%, Graphite: 5%, Al 2 o 3 : 5%.

Embodiment 3

[0019] Example 3, glycerin and water: 90%, MoS 2 : 5%, Graphite: 2%, Al 2 o 3 : 3%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

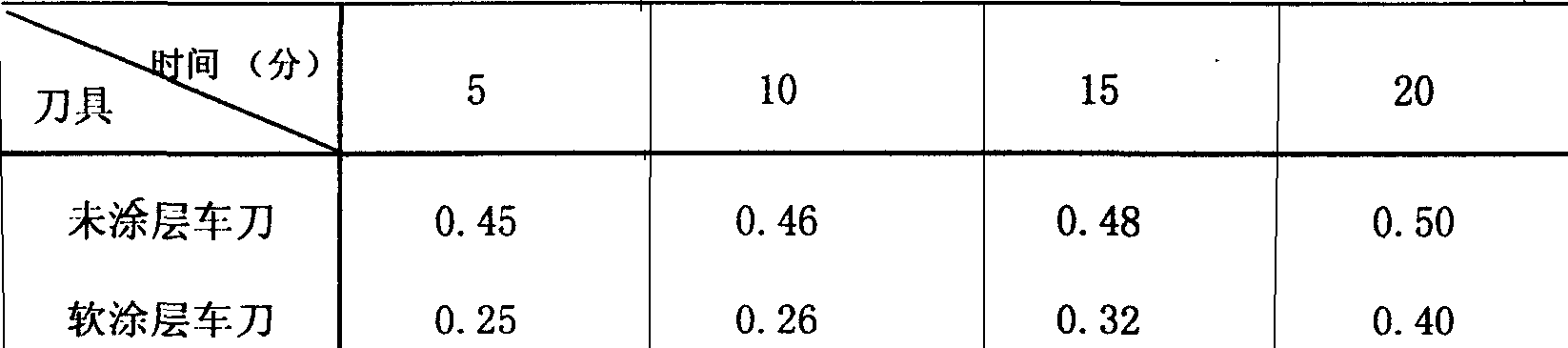

The invention relates to a high-speed steel cutter solid lubrication soft coating and its making method. The boiling coating compound solid lubrication material component and weight percentage are glycerol and water, 80-90; MoS2: 5-10; black lead, 1-5; Al2O3: 1-5. The dipping coating are epoxy resin, firming agent, 15-25; thinner, 50-60; MoS2:10-15; black lead, 3-5; Al2O3: 3-5. The manufacturing method of the soft coating includes the following steps: adopting boiling coating method that the pretreated cutter is put into the boiling coating fluid; and it does heating in water bath; the superficial of the cutter is adsorbed one layer compound solid lubrication; adopting dipping coating method that the cutter is put into the pretreated dipping coating fluid to solidify, make into cutter soft coating. The invention not only can realize dry cutting, but also has good cutting effect.

Description

technical field [0001] The invention relates to a dry cutting technology in which the solid lubrication technology is applied in the field of metal cutting, in particular to a preparation method for a solid lubrication soft coating of a high-speed steel cutting tool. Background technique: [0002] In metal cutting, in order to improve the processing quality and prolong the service life of the tool, metal cutting fluid is widely used. However, it is found that the use of cutting fluid will pose a hazard to the health of operators, and the discharge of waste liquid will also cause serious pollution to the environment, and the treatment cost of cutting fluid waste is very high. In order to realize the sustainable development of human society, the manufacturing industry must reduce resource consumption as much as possible and solve the environmental problems caused by it as much as possible. Therefore, the study of green cutting technology-dry cutting is the need of sustainable...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M105/14C10M107/34C10N40/22C10N50/02

Inventor 贾晓鸣张秀玲侯锁霞

Owner NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com