Method for enhancing burning mechanical burning performance

A technology of combustion performance and machinery, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve problems such as huge costs, and achieve the effect of improving combustion performance, saving energy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

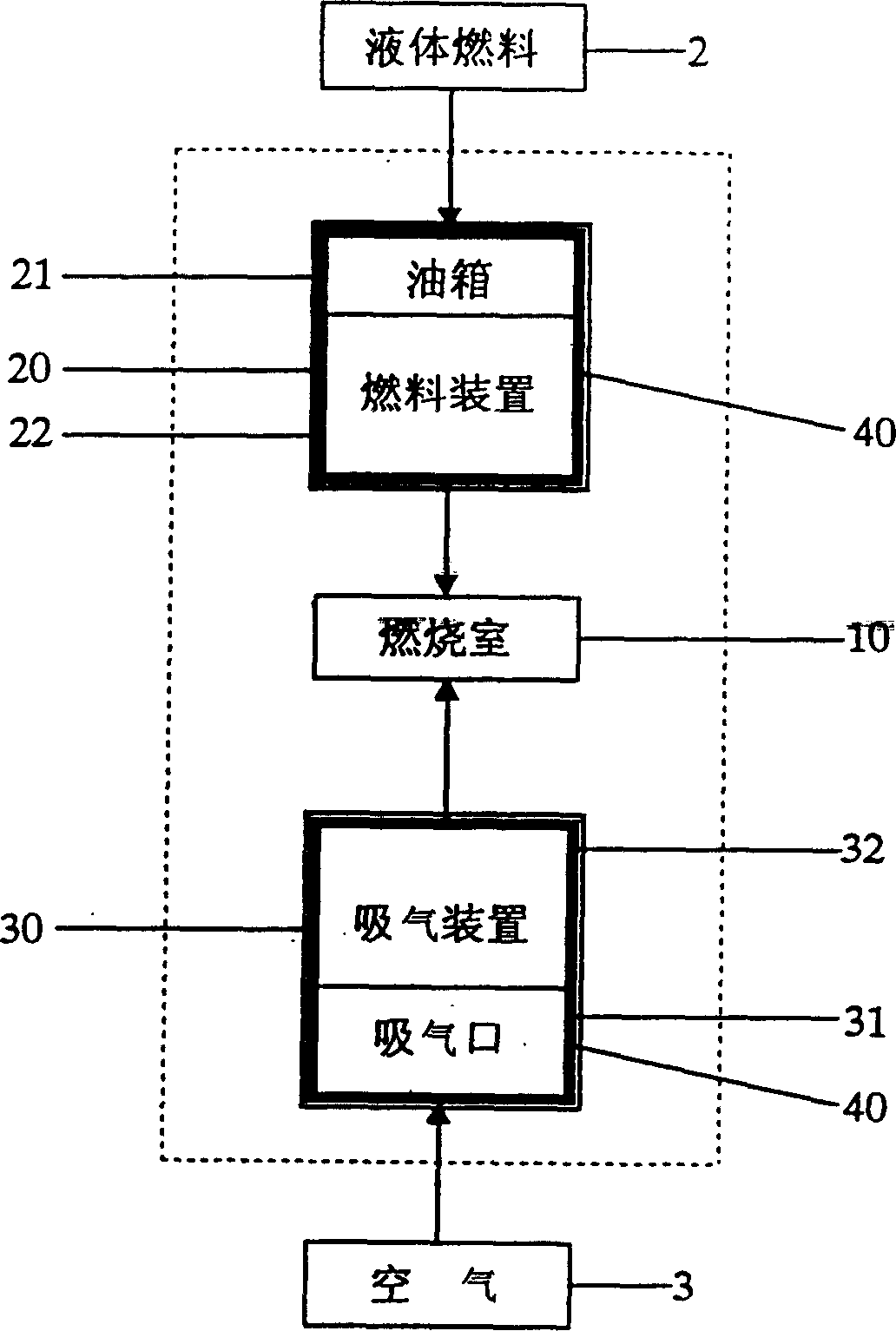

[0013] According to the drawings, an embodiment of the present invention will be described in detail. Among them, the combustion machine 1 is a general term for internal combustion machines such as various vehicles and industrial machines, combustion machines, and combustion furnaces. The fluid fuel 2 is supplied through the fuel supply mechanical part 20, and the air 3 is supplied through the air supply mechanical part 30 at the same time, and then the combustion chamber 10 That is, in a state of combustion.

[0014] The above-mentioned fuel supply mechanical part 20 is made up of a plurality of parts and devices (collectively referred to as fuel devices 22 herein) assembled together by the fuel tank 21 and the fluid fuel delivered to the combustion chamber. Here, the automobile is taken as an example to illustrate, and the corresponding parts are Fuel tanks, coal storage tanks, carburetors, fuel pumps, fuel filters, injection pumps, injection nozzles, and pipes connecting th...

Embodiment approach

[0017] The first embodiment of the present invention is: pulverize the silicon dioxide block, and mix the powder into the polyurethane paint to obtain the silicon dioxide-containing paint. The weight ratio of silicon dioxide and polyurethane coating is 15:85-30:70, preferably 20:80-25:75. This paint is applied to all or a part of the fuel supply mechanical part 20 and the air supply mechanical part 30 . If coating is performed on a part of both machine parts, coating may be performed only on the surface of the fuel tank 21 and the periphery of the suction hole 31 or on other parts. The position to be coated may be the inner surface, the outer surface or both sides of the designated part. The thickness of the coating is generally 6-10 microns, and the on-site temperature during coating can be 5-50°C. When the temperature is low in winter, or when the humidity is high in rainy days, hot air can also be used to blow and coax.

[0018] The second embodiment: not only the silica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com