Combined system of fuel battery and air source heat pump water heater

An air source heat pump and fuel cell technology, which is applied in the system field in the energy technology field, can solve the problems of increasing the complexity of system cost control and system power consumption, fluctuations in the seasonal energy efficiency ratio of compressors, and weakening system stability, etc., to achieve The effect of simplifying the structure, simplifying the structure and control, and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

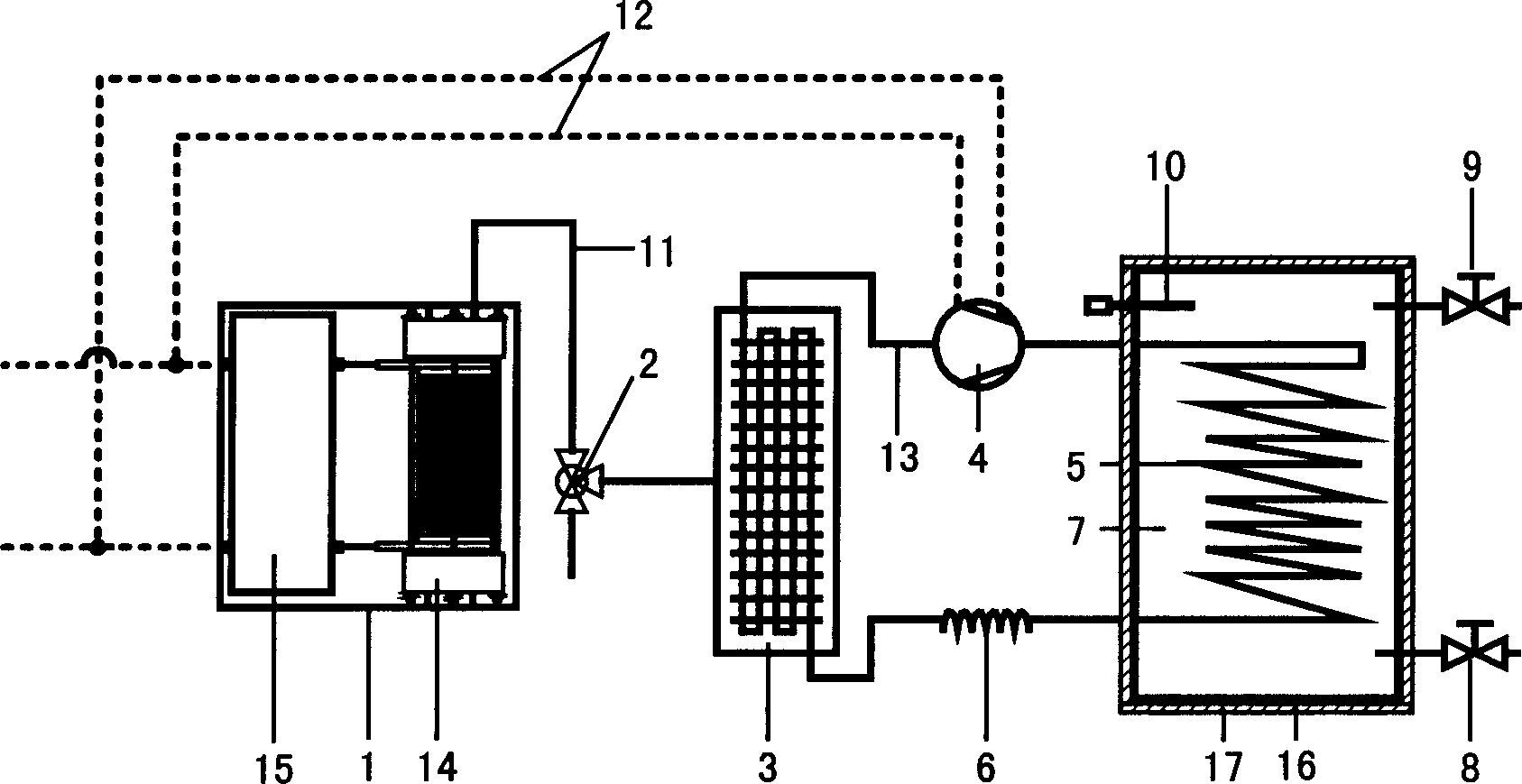

[0013] Such as figure 1 As shown, the present invention includes: a proton exchange membrane fuel cell subsystem 1, an air tail gas regulating valve 2, an evaporator 3, a compressor 4, a condensation coil 5, a throttling element 6, a hot water tank 7, a cold water regulating valve 8, Hot water regulating valve 9, temperature sensor 10. The proton exchange membrane fuel cell subsystem 1 is connected to the evaporator 3 through a stainless steel pipe 11 and an air tail gas regulating valve 2 . The proton exchange membrane fuel cell subsystem 1 is electrically connected to the compressor 4 through wires 12 . The evaporator 3 , the compressor 4 , the condensing coil 5 , and the throttling element 6 are connected in series through copper tubes 13 to form a heat pump subsystem. The condensing coil 5 is placed in the hot water tank 7 . The cold water regulating valve 8 is installed on the hot water tank 7, and its position is lower than the horizontal position of the condensing co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com