Display device and method for manufacturing the same

A technology of a display device and a manufacturing method, which is applied in the directions of lighting devices, semiconductor/solid-state device manufacturing, static indicators, etc., can solve the problems of low-cost production obstacles, inability to become products, and inability to manufacture panels, etc., and achieves the goal of reducing manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

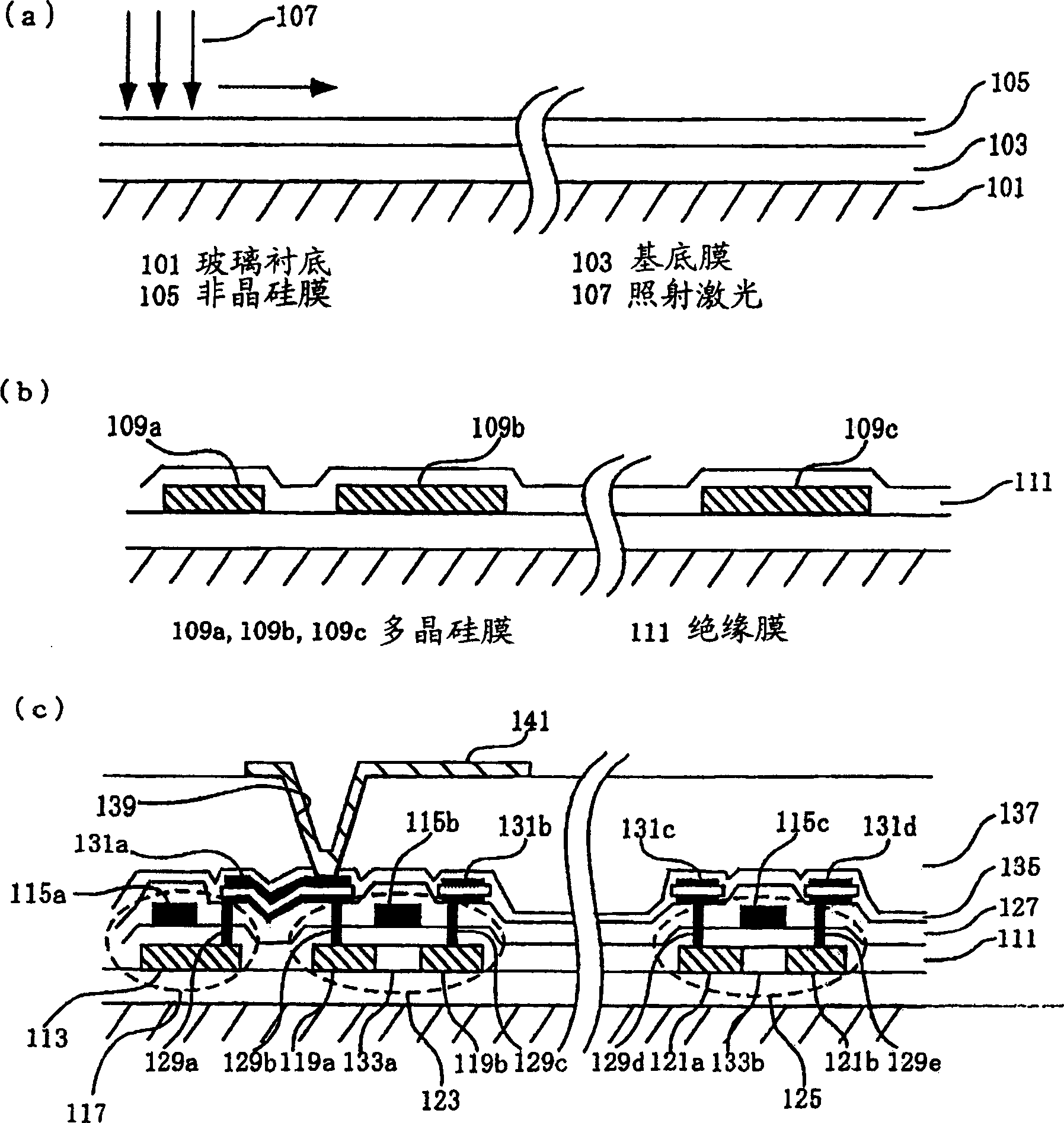

[0034] 1 is a schematic cross-sectional view illustrating a method of manufacturing a thin-film transistor using low-temperature polysilicon and a method of manufacturing a liquid crystal display device using the low-temperature polysilicon according to Embodiment 1 of the present invention. In addition, in the explanatory drawings used in the respective embodiments described below, the same or corresponding parts are denoted by the same reference numerals, and description thereof will be omitted.

[0035] Referring to FIG. 1(a), in the liquid crystal display device in this embodiment mode, firstly, a film with a film thickness of 2500 Å is formed on a glass substrate 101 by, for example, PECVD (Plasma Enhanced Chemical Vapor Deposition: plasma enhanced chemical vapor deposition) method. The base film 103 is composed of left and right silicon oxide films. For the base film 103, a laminated film such as a silicon nitride film, a silicon oxide film, or the like may be used. An ...

Embodiment approach 2

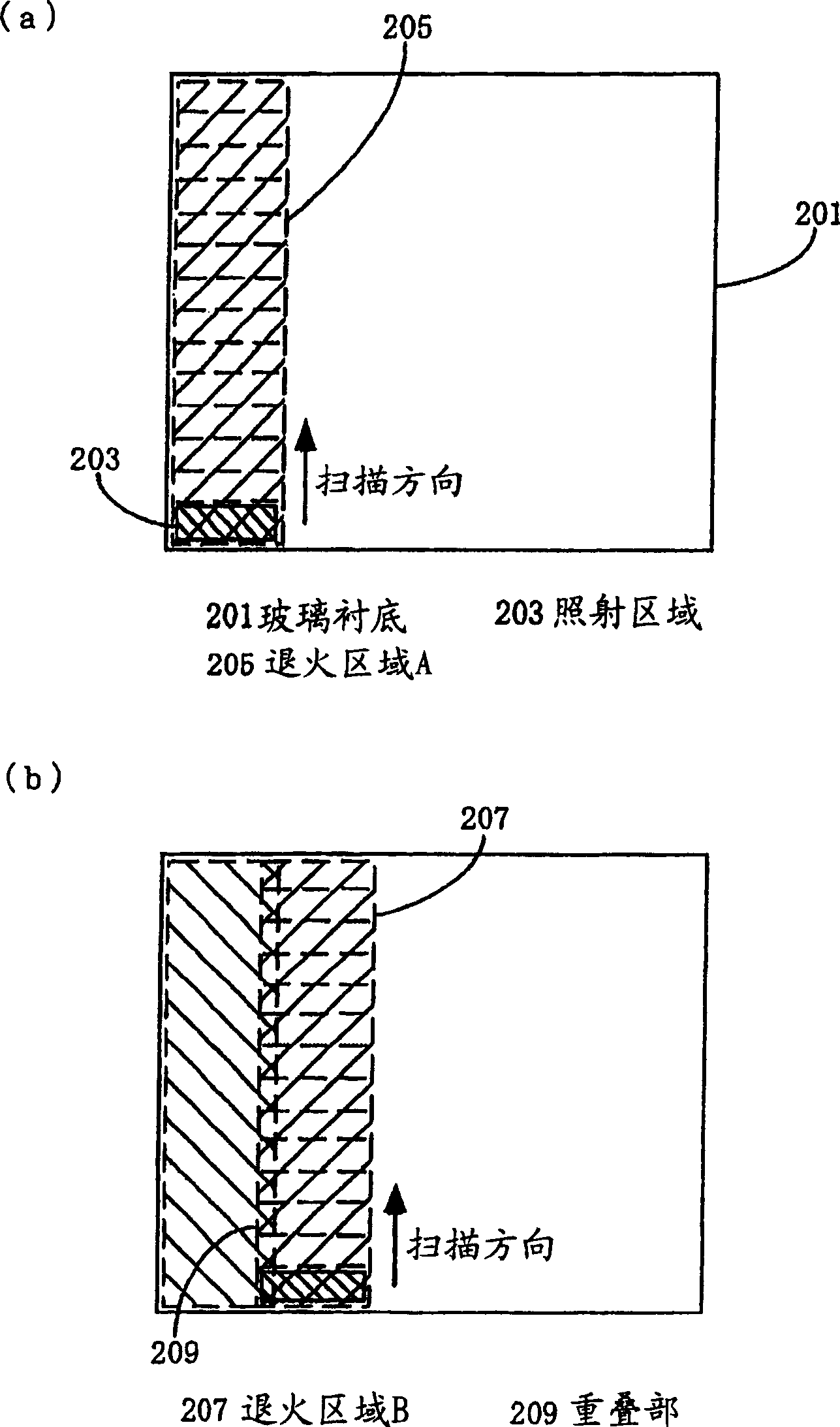

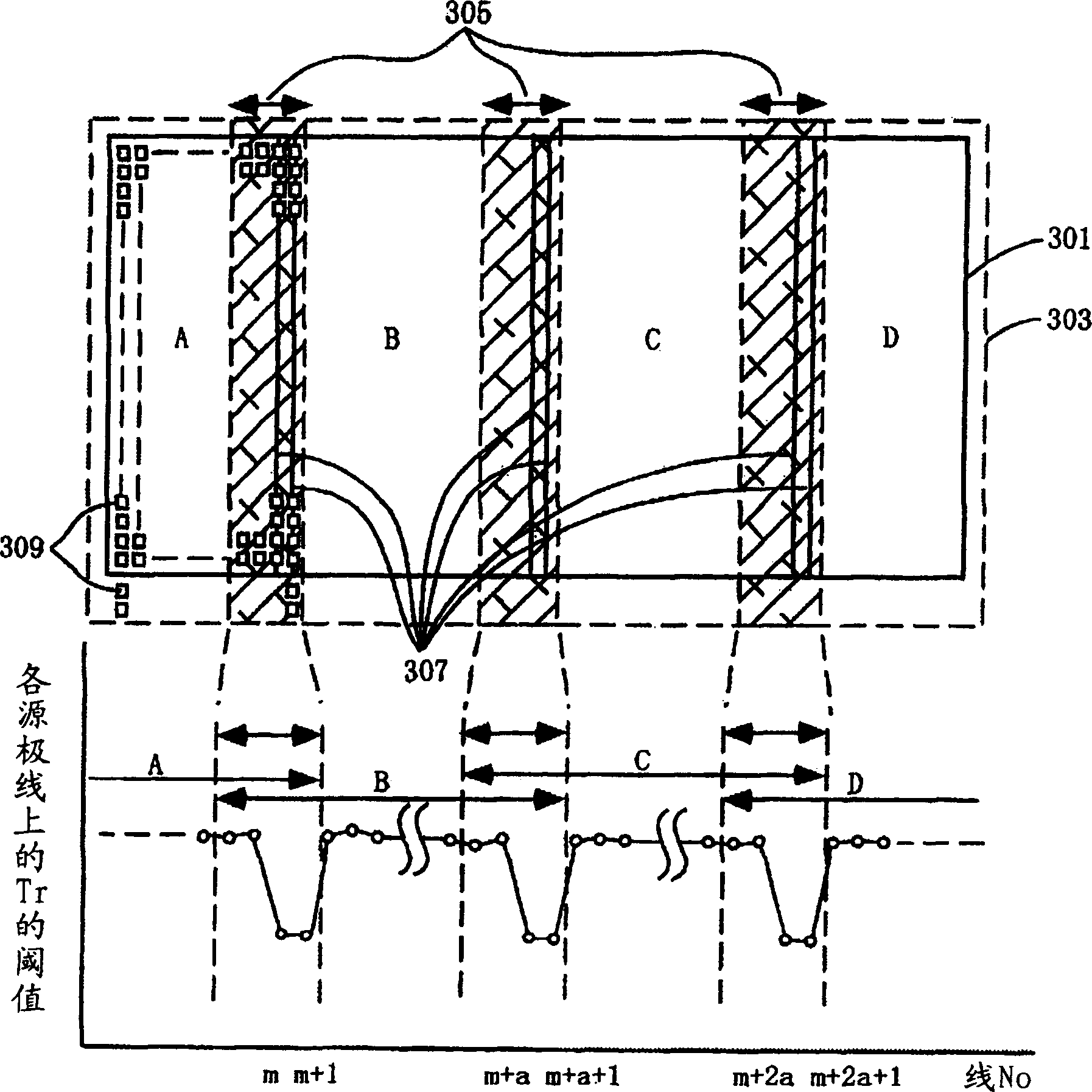

[0056] In Embodiment 1, the panel is arranged so that the overlapping portion of laser light irradiation in laser annealing is parallel to the source lines, and the display unevenness caused by the fluctuation of the threshold value of the thin film transistor on the source line in the overlapping portion is hardly visible. was identified above. On the other hand, in this embodiment, the panel is arranged so that the overlapping portion irradiated with laser light is parallel to the gate lines, so that the display unevenness caused by the fluctuation of the threshold value of the thin film transistor on the gate line in the overlapping portion is hardly visible visually. be identified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com