Process for preparing cantharides xanthin

A technology of canthaxanthin and oxidant, which is applied in the fields of oxidative preparation of carbonyl compounds and organic chemistry, can solve problems such as difficulty in initiating oxidation and unstable process, and achieve the effects of stable reaction, simple process operation, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

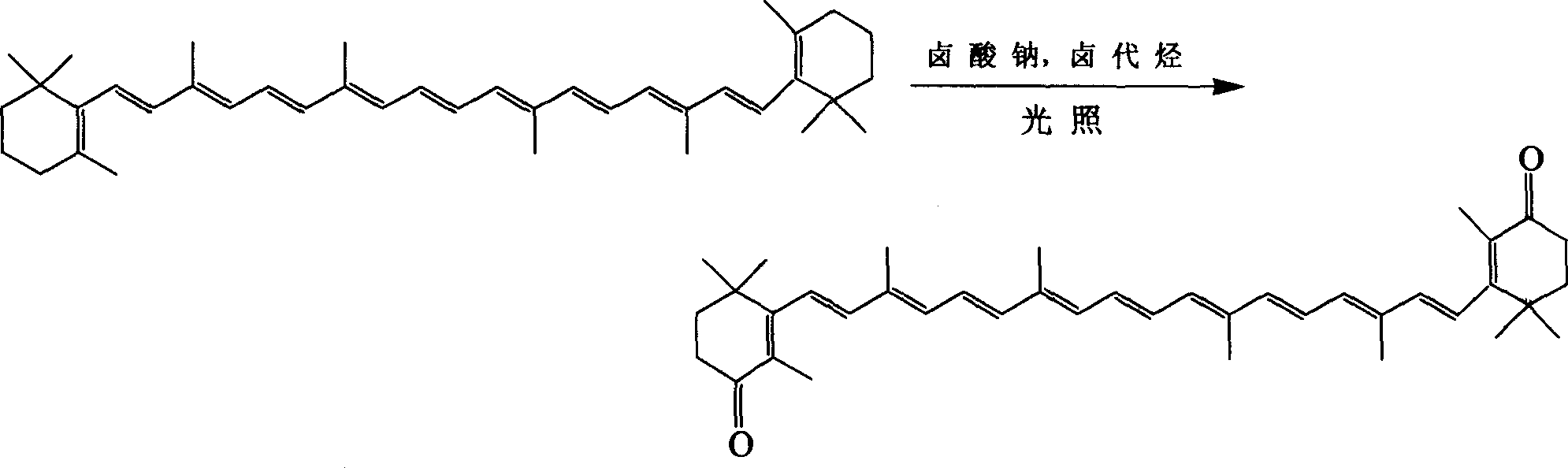

Method used

Image

Examples

Embodiment 1

[0020] Get 10g beta-carotene and place it in a 500ml reaction kettle, add 250ml dichloromethane, then, get 20g sodium chlorate and dissolve it with 200ml water, then use W(H 2 SO 4 ) = 5% solution to adjust the pH to 3.5, add it to the reaction kettle, control the temperature at 40°C, irradiate the reaction solution with an 800W incandescent lamp, and stir vigorously, react for 4 hours, separate the organic layer, wash with water 3 times, It was then dried with anhydrous sodium sulfate, filtered, and the solution was rotatably evaporated. The residue was washed twice with 200 ml of methanol, and then crystallized with chloroform-methanol to obtain 7.2 g of purple needle-shaped canthaxanthin crystals, with a yield of 70.4%. The obtained canthaxanthin crystal has a melting point of 206-208° C., which is measured according to the method of FAD / WHO, and the product quality meets the food standard stipulated by FAD / WHO.

Embodiment 2

[0022] 10g beta-carotene is placed in 500ml reaction kettle, adds 250ml dichloromethane, then, gets 25g sodium bromate and dissolves with 200ml water, then with W(H 2 SO 4 ) = 5% solution to adjust the pH to 4, add it to the reaction kettle, control the temperature at 35°C, place a 500W mercury lamp on the surface of the reaction liquid to irradiate, and stir vigorously, react for 5 hours, separate the organic layer, and wash with water 3 times , and then dried with anhydrous sodium sulfate, filtered, and the solution was rotary evaporated, the residue was washed twice with 200ml of methanol, and then crystallized with chloroform-methanol to obtain 7.6g of purple needle-shaped canthaxanthin crystals, with a yield of 74.3%. The obtained cantharidin crystals had a melting point of 206-208°C.

Embodiment 3

[0024] Get 10g beta-carotene and place it in a 500ml reaction kettle, add 300ml chloroform, then, get 20g sodium chlorate and dissolve it with 200ml water, then use W(H 2 SO 4 ) = 5% solution to adjust the pH to 3, add it to the reaction kettle, control the temperature at 30 ° C, place a 200W sodium lamp in the reaction solution for irradiation, and stir vigorously, react for 6 hours, separate the organic layer, wash 3 times with water, and then Dry over anhydrous sodium sulfate, filter, and rotary evaporate the solution. The residue is washed twice with 200 ml of methanol, and then crystallized with chloroform-methanol to obtain 6.9 g of purple needle-shaped canthaxanthin crystals, with a yield of 67.5%. The obtained cantharidin crystals had a melting point of 206-208°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com