Low surface energy fluorine carbon antifouling paint

An antifouling coating and low surface energy technology, which is applied in the direction of antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems that cannot be used for long-term antifouling and can only be used for high-speed ships, to prevent Effects of marine bioaccumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Production of low surface energy fluorocarbon coating

[0036] The weight ratio of A and B components is 13:1, and the formula of A component is as follows:

[0037] Fluorocarbon resin (F-100) 45kg, zinc oxide 7.5kg, titanium dioxide 8kg, antifouling agent 35kg, (including cuprous oxide 27.5kg, SeaNine2117kg, capsaicin 0.5kg), methyl polysiloxane 3kg, BYK -161 0.9kg, BYK-306 0.3kg, BYK-066 0.3kg.

[0038] Group B is DESMODUR L75;

[0039] Prepare as follows:

[0040] a. According to the formula of component A, add fluororesin, zinc oxide, antifouling agent, pigment and filler, organosilicon compound and a mixed solvent whose weight is 2 / 3 of the total weight of the solvent into the container; disperse at high speed for 2 hours at 2000rpm When the fineness is 50μm, add various additives according to the formula amount, and adjust the viscosity to 60d / s with the remaining mixed solvent, stir well, filter with a 100-mesh filter, and measure and pack.

...

Embodiment 2

[0042] Embodiment 2: Preparation of first component in low surface energy fluorocarbon coating

[0043] The weight ratio of A and B components is 14:1, and the formula of A component is as follows:

[0044]Fluorocarbon resin (F-200) 40kg, zinc oxide 11kg, titanium dioxide 12kg, antifouling agent 32kg (including cuprous oxide 27.5kg, SeaNine2117kg, capsaicin 0.5kg), dimethylpolysiloxane 5kg, BYK- 163 0.9kg, SF-800 0.3kg, SF-707 0.3kg.

[0045] A component is prepared according to the following steps:

[0046] Add fluororesin, zinc oxide, antifouling agent, pigments and fillers, organosilicon compound and a mixed solvent whose weight is 3 / 4 of the total weight of the solvent into the container according to the formula of component A; disperse at high speed for 2 hours at 2000rpm, when the fineness When it is 40μm, add various additives according to the formula amount, and adjust the viscosity to 80d / s with the remaining mixed solvent, stir well, filter with a 120-mesh filter, ...

Embodiment 3

[0047] Embodiment 3: the production of low surface energy fluorocarbon coating

[0048] According to the method described in embodiment 1, low surface energy fluorocarbon paint is produced, and the weight ratio of first and second components is 14: 1, and the formula of first component is as follows:

[0049] Fluorocarbon resin (F-200) 45kg, zinc oxide 13kg, titanium dioxide 10kg, antifouling agent 35kg (including cuprous oxide 25kg, TCPM7kg, SK1100 3kg), BYK-3700 5kg, SF-725 0.9kg, SF-800 0.3kg, SF-707 0.3kg.

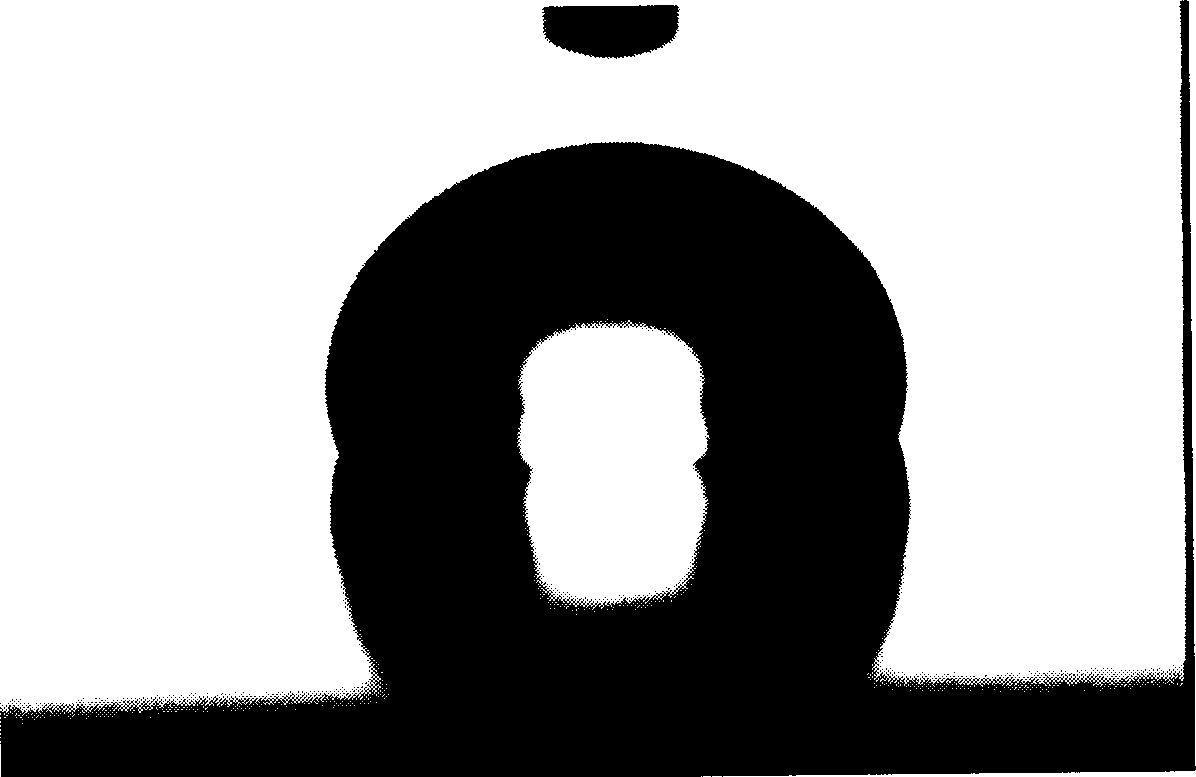

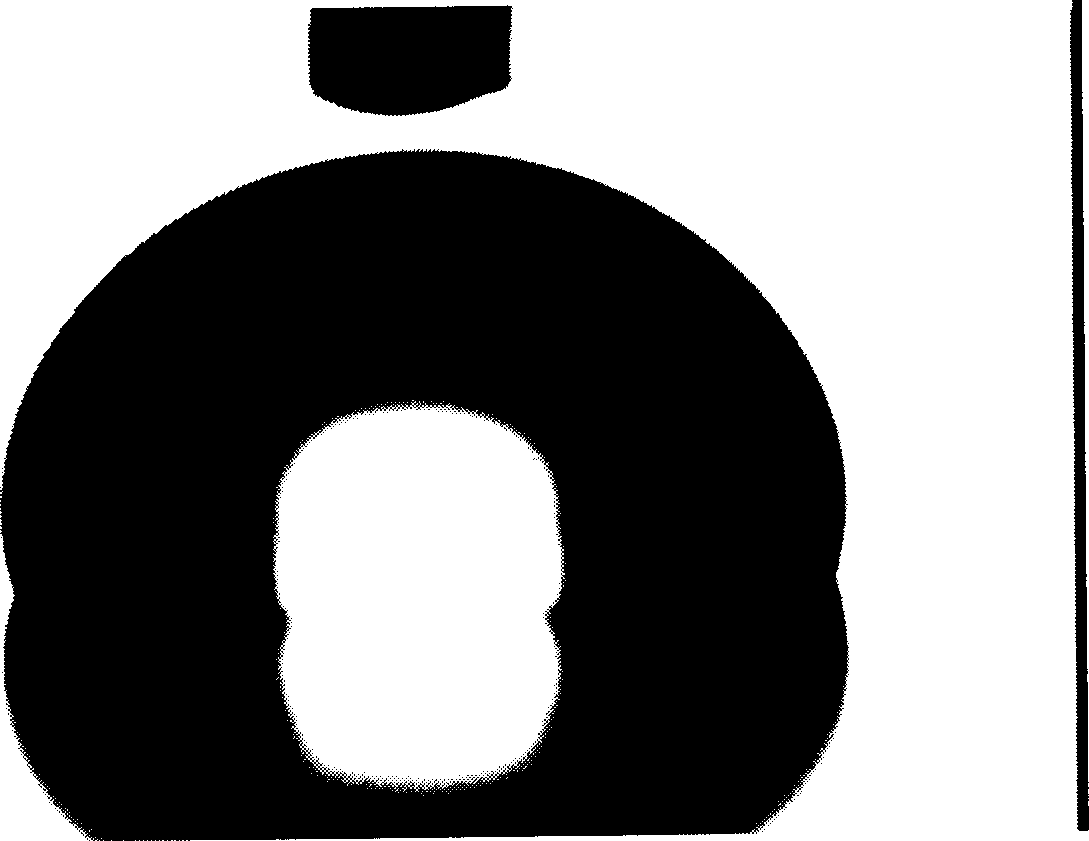

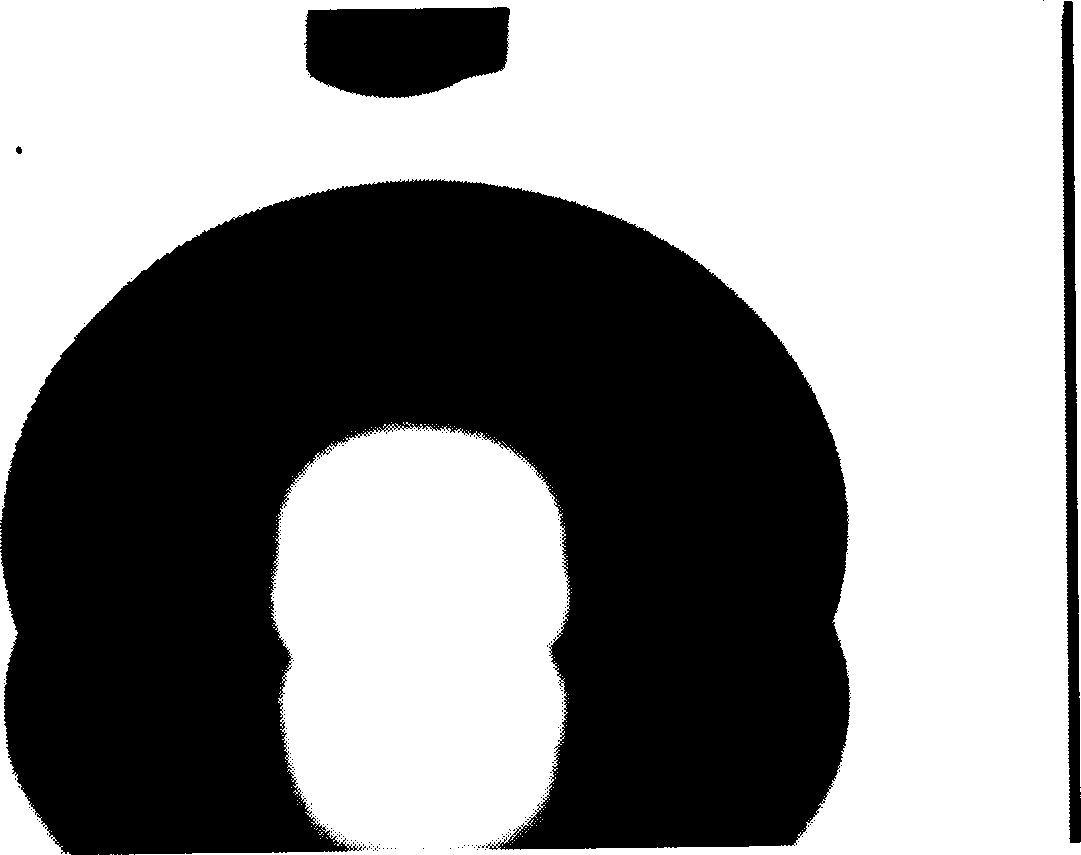

[0050] The contact angle of antifouling coating and deionized water measured by OCA20 Dataphysics video contact angle measuring instrument is shown in Table 1. The calculated coating surface energy is shown in Table 2. The contact angle measurement video image of the embodiment coating and deionized water is shown in figure 1 .

[0051] Example

[0052] example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com