Process for making ceramics utensils

A technology for making crafts and utensils, which is applied in the field of ceramic utensils, which can solve the problems of high cost, popping, high scrap rate, etc., and achieve the effect of sparse lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

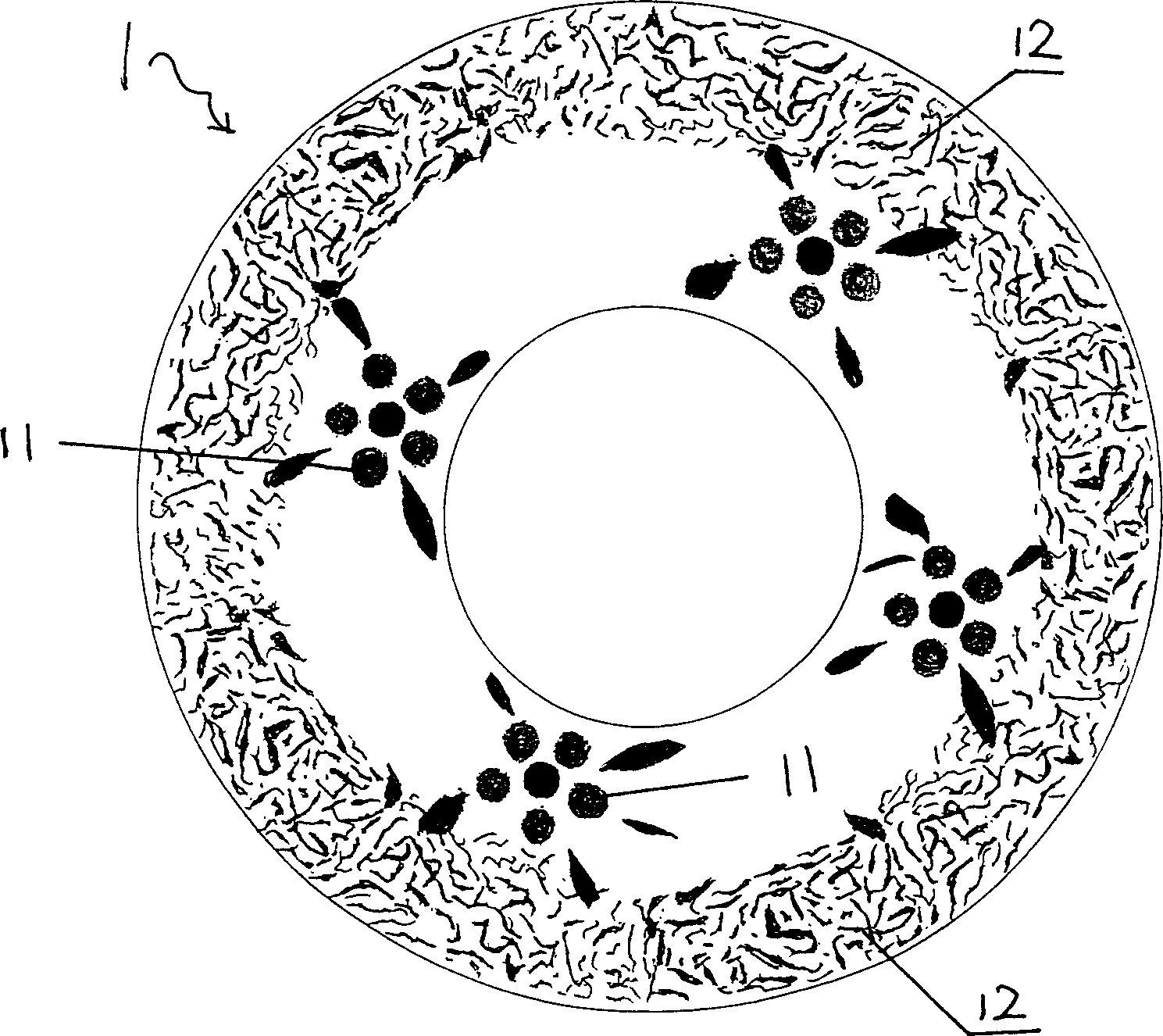

[0023] The manufacturing process of the ceramic vessel includes the following main steps: ①, making the ceramic disc vessel mud, and then sending the disc vessel mud into the kiln for biscuit firing to form a ceramic disc vessel; ②, taking coreless yarn Dip the maroon pigment into the pigment solution with the yarn ball (yarn diameter is 0.5mm), and then touch the coreless yarn ball dipped in the pigment to the edge area of the upper surface of the ceramic disc vessel, and perform this action several times , thereby gradually forming a pattern 12 made of yarn mass imprints on the edge region of the upper surface of the ceramic disc vessel; while the inner ring region is manually drawn with four groups of patterns 11 with a brush, such as figure 1 Shown; ③. Glaze the plain body of the ceramic disc vessel, so that the pattern imprinted by the yarn ball and the four groups of patterns drawn by hand with a brush are all covered under the glaze layer, and then put into the kiln gl...

Embodiment 2

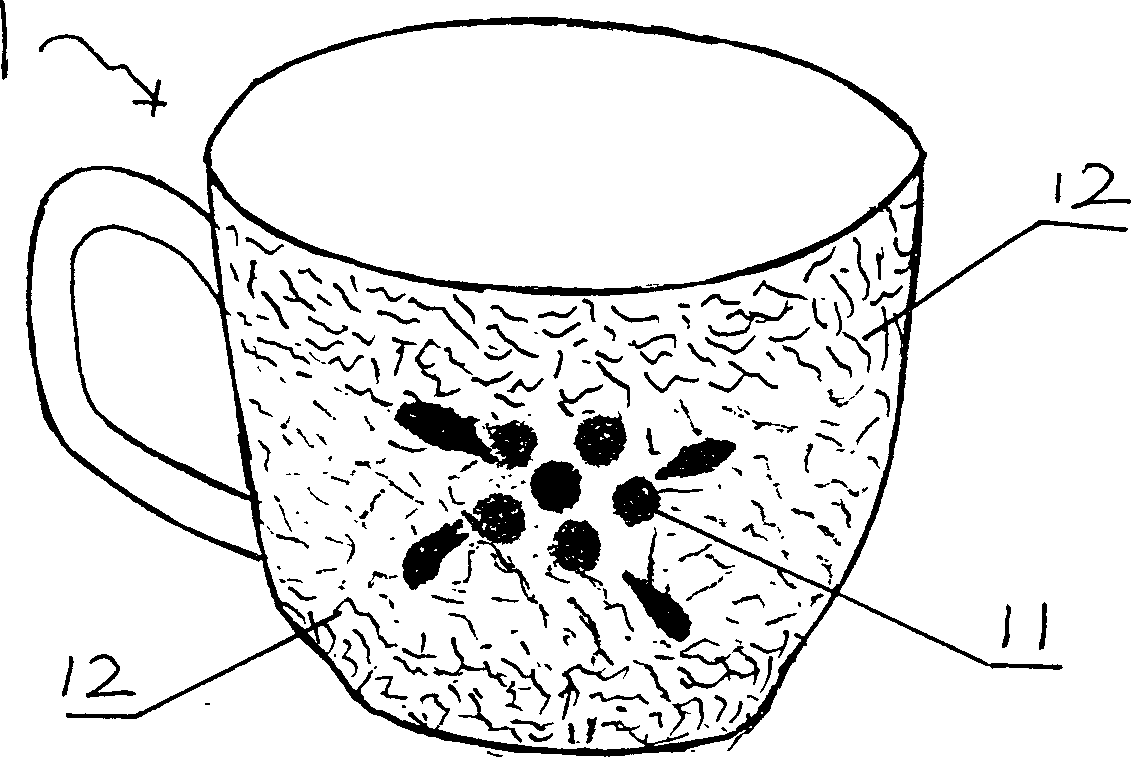

[0025] The manufacturing process of the ceramic vessel includes the following main steps: ①, making the ceramic cup mud, and then sending the ceramic cup mud into the kiln for biscuit firing to form a ceramic cup plain; The diameter is 0.2mm) to dip the pigment into the pigment solution, and then touch the coreless yarn ball dipped in the pigment to the outer surface of the ceramic cup plain tire, and perform this action several times, gradually forming a A pattern 12 of yarn ball imprints, such as figure 2 Shown; The pattern that yarn mass imprinting constitutes is used as background pattern again, on background pattern, draws pattern 11 by superimposing with paintbrush manually; The pattern 12 drawn with a paintbrush is all covered under the glaze layer, and then fired in a kiln glaze to obtain a ceramic cup product, such as figure 2 as shown ( figure 2 It is drawn according to the actual product of a ceramic cup produced by the applicant).

Embodiment 3

[0027] The manufacturing process of the ceramic vessel includes the following main steps: ①, making the ceramic disc vessel mud, and then sending the disc vessel mud into the kiln for biscuit firing to form a ceramic disc vessel; ②, taking coreless yarn The yarn ball (yarn diameter is 1.5mm) dips the pigment into the pigment solution, and then touches the coreless yarn ball dipped in the pigment to the entire upper surface area of the ceramic disc vessel, and performs this action several times, gradually A pattern composed of imprinted yarn balls is formed on the entire upper surface area of the plain body of the ceramic disc vessel; ③, glaze the plain body of the ceramic disc vessel so that the pattern imprinted by the yarn balls is covered under the glaze layer, and then put into the kiln for glaze firing And get ceramic utensils.

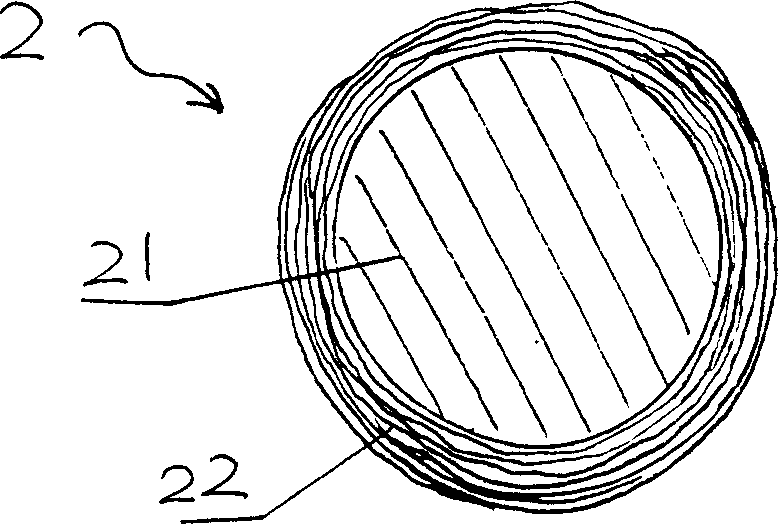

[0028] In this application document, the so-called "coreless yarn cluster" is relative to the "cored yarn cluster"; image 3 , Figure 4 W...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com