Constant backpressure and proportion controlled sinter apparatus HAGC System

A proportional control and hydraulic pressing technology, applied in the field of hydraulic machinery, can solve the problems of high cost of gas fusion pressing process, inability to control the low pressure in the initial section, and affecting the pressure of the low pressure section, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

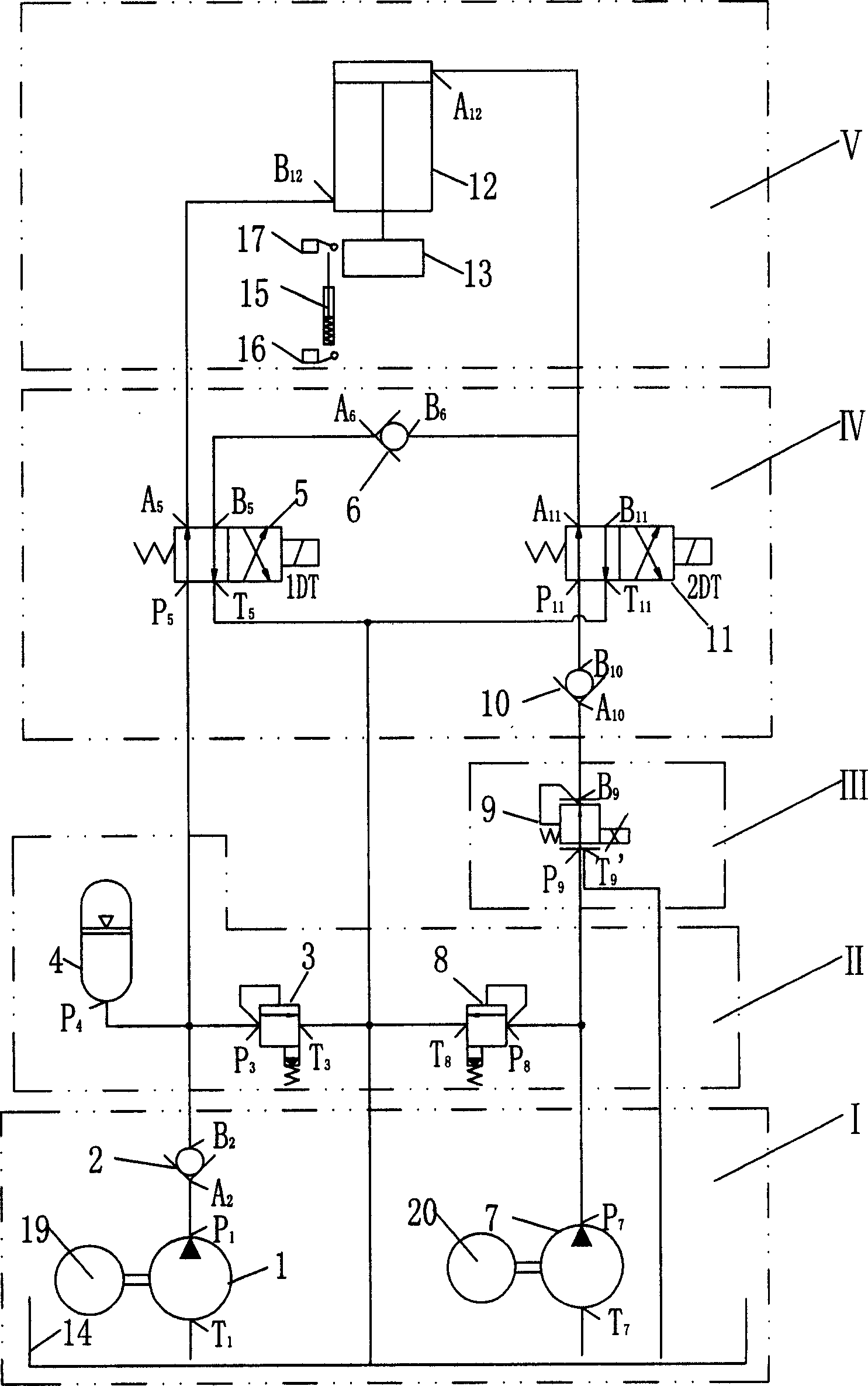

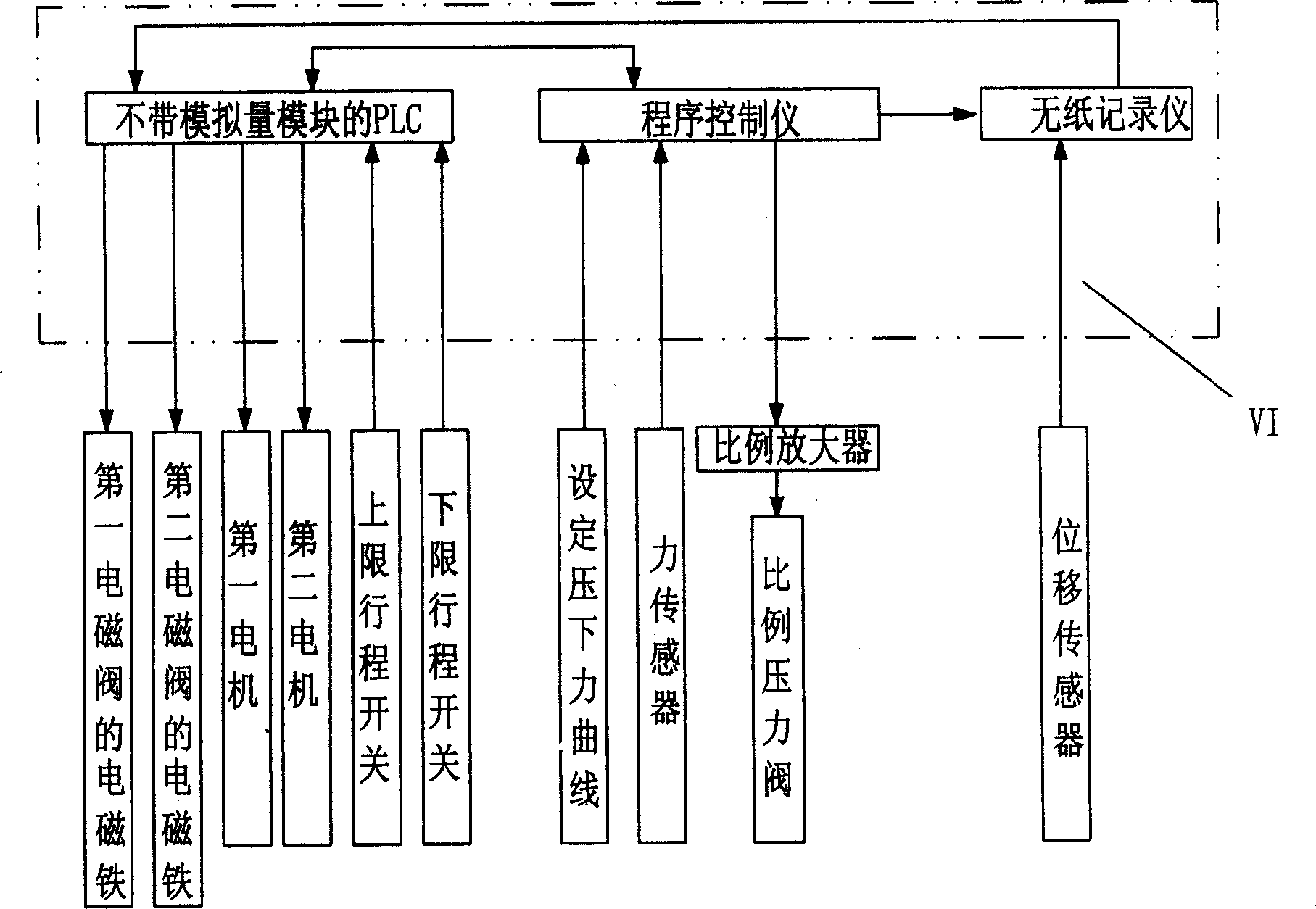

[0030] Embodiment 1: The solenoid valves in the hydraulic system are two-position four-way electromagnetic reversing valves, and the proportional pressure valves are proportional pressure reducing valves. Such as figure 1 and image 3 As shown, its structure includes oil source part I, safety protection and voltage stabilization part II, proportional control part III, action switching part IV, pressing device part V, electrical control part VI, and an oil outlet of oil source part I in sequence Through the connection between the safety protection and voltage stabilization part II, the action switching part VI and the hydraulic cylinder of the pressing device part V, the other oil outlet of the oil source part I passes through the safety protection and voltage stabilization part II and the proportional control part III in turn. , Rodless cavity A of the hydraulic cylinder of the action switching part IV and the depressing device part V 12 The oil return port and the oil drain...

Embodiment 2

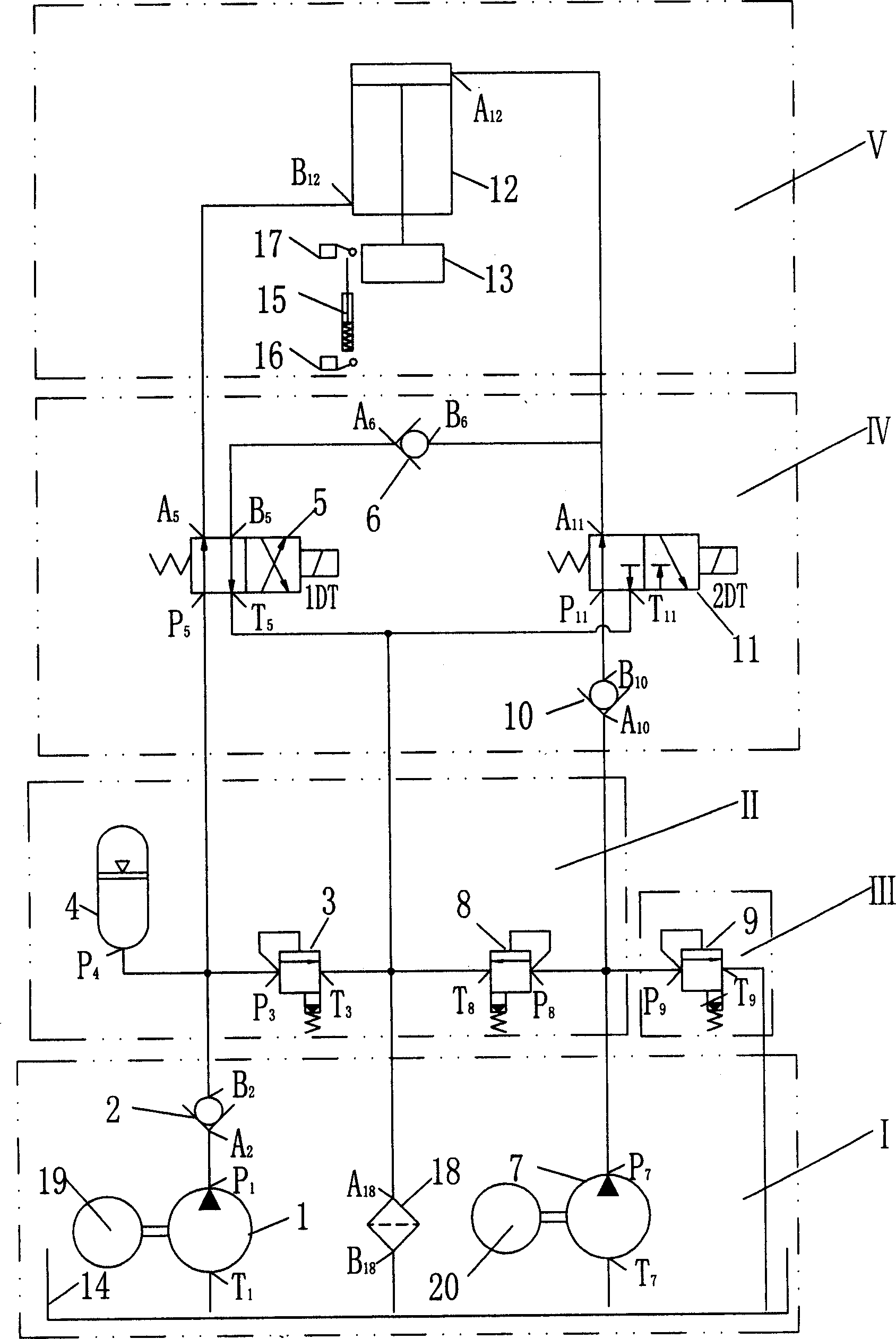

[0038] Embodiment 2: In the hydraulic system, the first solenoid valve adopts a two-position four-way electromagnetic reversing valve, the second solenoid valve adopts a two-position three-way electromagnetic reversing valve, the proportional pressure valve adopts a proportional overflow valve, and the safety protection and voltage stabilization part An oil return filter is connected between the oil return ports of the two relief valves and the oil tank. Such as figure 2 , Figure 4 As shown, its structure includes oil source part I, safety protection and voltage stabilization part II, proportional control part III, action switching part IV, pressing device part V, electrical control part VI, and an oil outlet of oil source part I in sequence Through the connection between the safety protection and voltage stabilization part II, the action switching part IV and the hydraulic cylinder of the pressing device part V, the other oil outlet of the oil source part I passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com