Batch synthesis method of hollow nanometer/micrometer zinc oxide ball

A zinc oxide nanometer and synthesis method technology, applied in the direction of zinc oxide/zinc hydroxide, etc., to achieve the effect of improving room temperature luminescence performance and easy synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

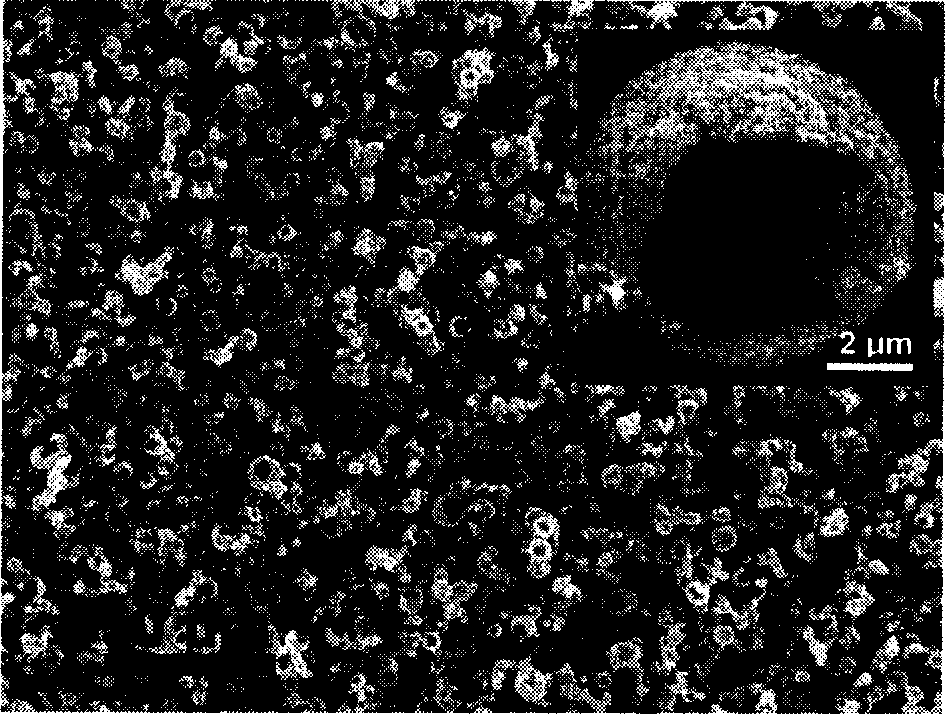

[0029] The diameter of the reactor was 20 mm, and the length of the electric furnace was 200 mm. The flow rate of argon (99.9%) is 115sccm, and the flow rate of oxygen (99.9%) is 0.1sccm. The graphite material is used as the container and deposition substrate of the zinc powder. The particle size of the zinc powder is less than 25μm (pure zinc content> 99.2%), and the thickness of the zinc powder is placed About 1.5mm. The reaction temperature was 680°C, and the reaction time was 20 minutes. Batch preparation of pure hollow spherical and hemispherical zinc oxide, the product morphology is as follows figure 1 shown.

Embodiment 2

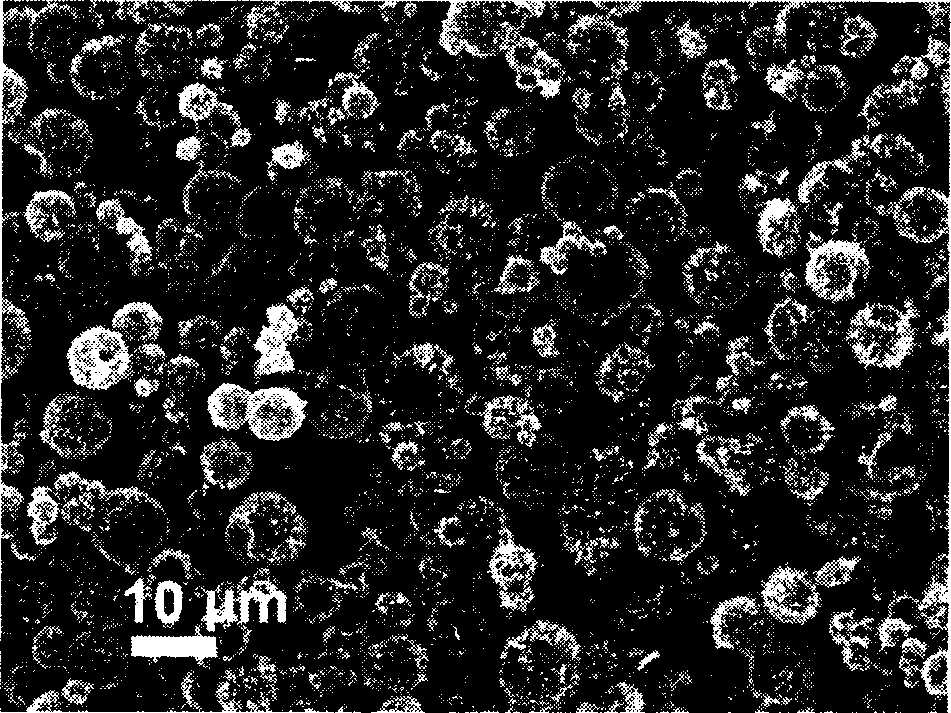

[0031] The diameter of the reactor was 20 mm, and the length of the electric furnace was 200 mm. The flow rate of argon (99.9%) is 80sccm, and the flow rate of oxygen (99.9%) is 8sccm. The graphite material is used as the container and deposition substrate of the zinc powder. The particle size of the zinc powder is less than 25μm (pure zinc content> 99.2%). 3mm; the reaction temperature is 600°C, and the reaction time is 40min. The sea urchin-shaped zinc oxide hollow sphere material is prepared in batches, and the material is an assembly of zinc oxide nanowires and hollow spheres. The shape of the product is as follows figure 2 shown.

Embodiment 3

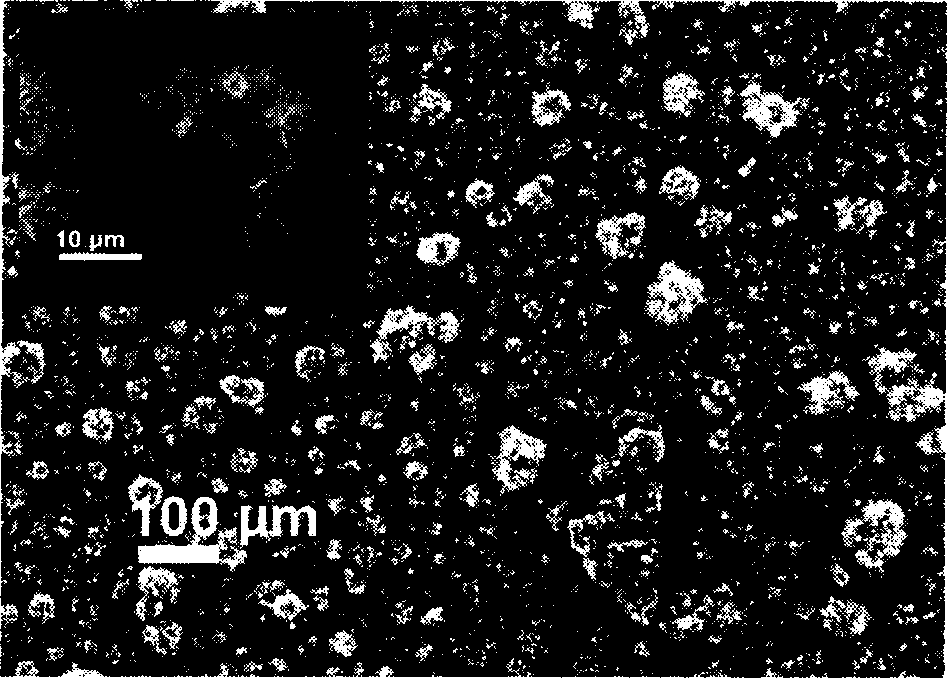

[0033]The diameter of the reactor was 20 mm, and the length of the electric furnace was 200 mm. The flow rate of argon gas (99.9%) was 20 sccm, and the zinc oxide powder (99.9%) and the graphite powder (99.9%) were mixed and ground in 1:1 as the raw material. The raw materials were put into the reactor, then rapidly heated to 950°C, and the tin-plated iron sheet was used as the substrate to collect the zinc oxide product in the temperature range of 300-700°C; the reaction time was 60 minutes. The sea urchin-shaped zinc oxide hollow sphere material is prepared in batches, and the material is an assembly of zinc oxide nanobelts and hollow spheres. The shape of the product is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com