Transplantable ultrathin nano-porous gold film and method for preparing the same

A nanoporous and gold film technology, which is applied in the field of nanomaterials and thin film materials, can solve the problems of difficult mass production and difficult preparation of uniform nanoporous metal thin films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further describe the ultra-thin nanoporous gold film that the present invention proposes below by embodiment

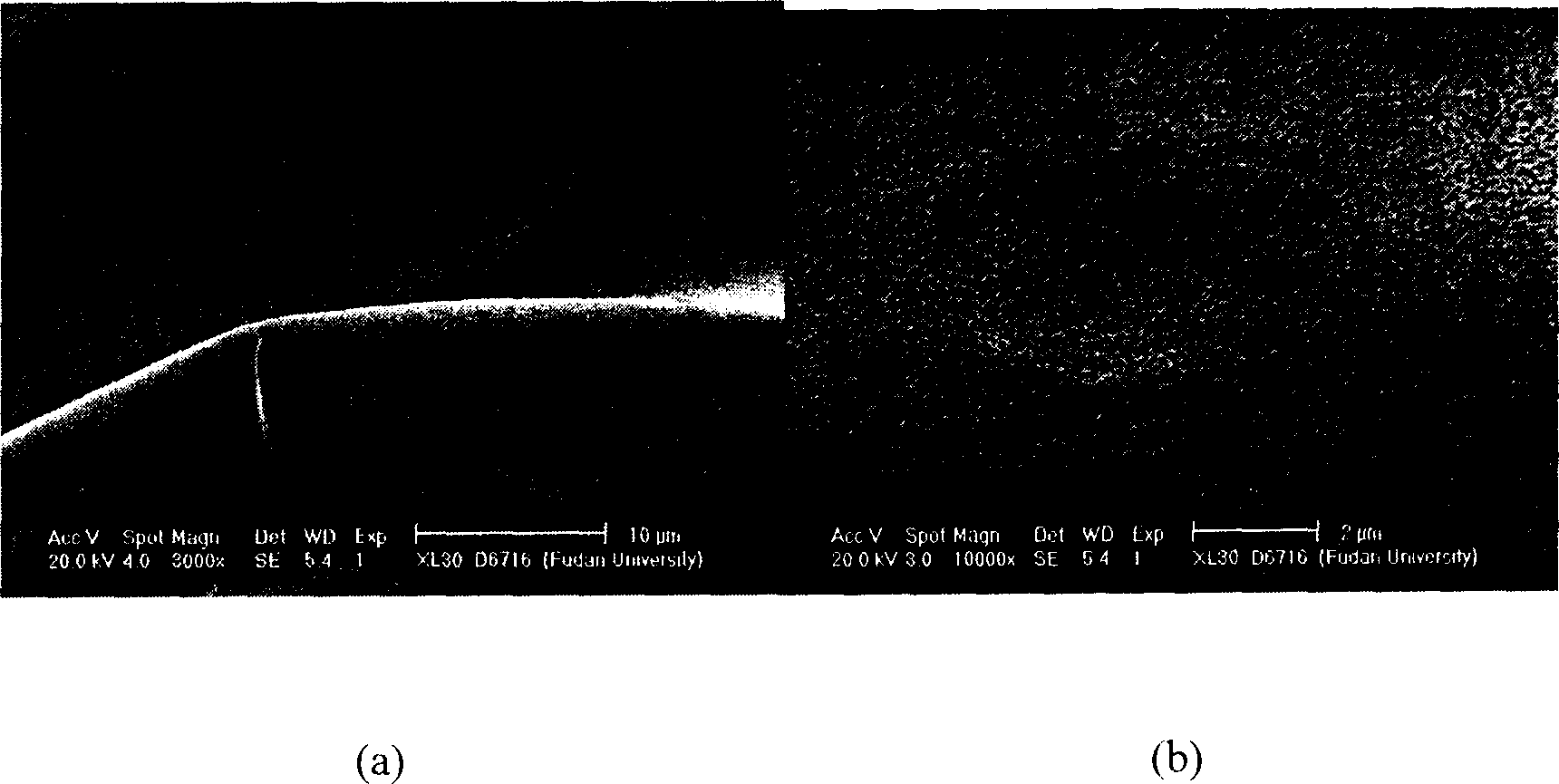

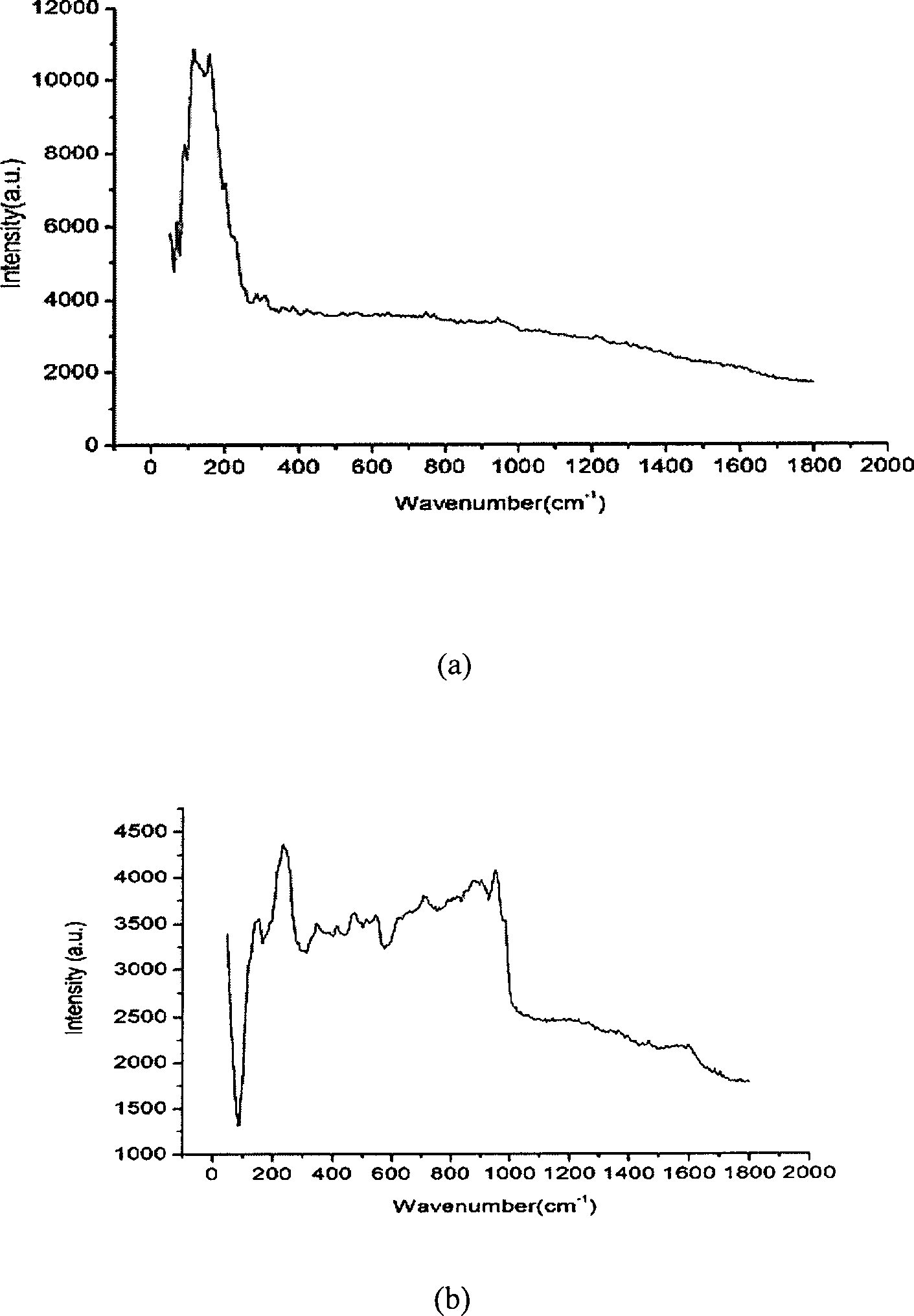

[0020] Using freshly cleaved mica flakes as a substrate, the 4 × 10 -3 Under the vacuum degree of Pa, the mixture of Au and Cu (Au x Cu 1-x ). The thickness of the alloy film was monitored using a quartz oscillator. Then, the samples were put into an oven and annealed in the air atmosphere at a temperature of 200°C for 25 hours. Afterwards, the film was immersed in 0.1mol / L dilute hydrochloric acid for corrosion treatment to remove Cu oxide and unoxidized nano-Cu in the film. In the process of corroding with hydrochloric acid, the gold film will spontaneously peel off from the mica substrate, and the sample area of the peeled gold film can reach 4cm 2 about. The sample was washed repeatedly with deionized water to remove the reaction products and other impurities adsorbed on the surface of the film. Finally, store in deionized water for later use.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com