Preparation method of silicon micro/nanometer line array with controllable dimension

A technology of nanowire array and silicon micro, which is applied in the field of preparation of micro/nanowire array, can solve problems such as difficult device use, and achieve the effects of low cost, simple process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

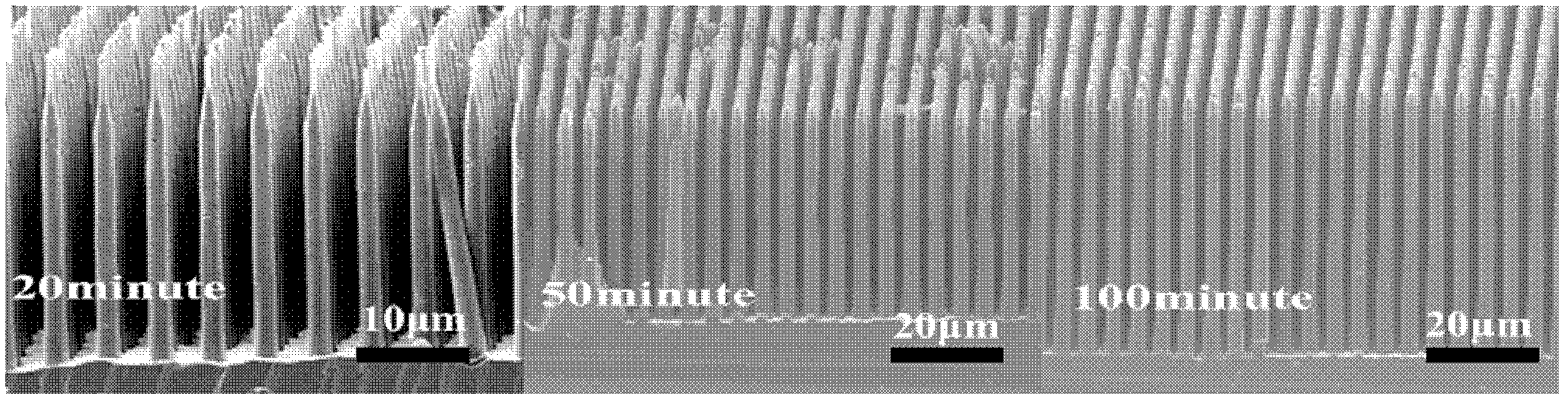

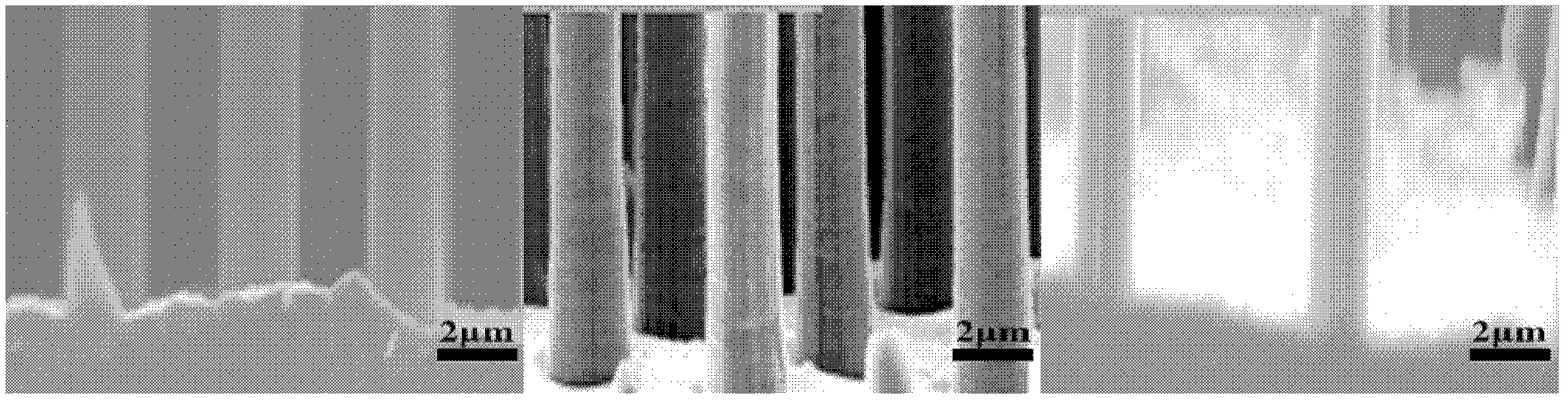

[0032] Based on the n-type silicon wafer with (100) crystal orientation and resistivity of 5Ωcm, place the silicon wafer in deionized water and acetone in sequence for ultrasonic cleaning for 15 minutes, and then immerse in piranha washing solution at 60°C After 10 minutes, take it out and dry it to be sample A. Spin-coat photoresist AZ5206 on the surface of sample A, and form a photoresist layer with a thickness of 300-500 nanometers after drying; it is made in the form of a silicon micro / nano wire array Contact mask, using a contact mask with silicon micro / nano wire array patterns to expose the photoresist layer to UV for 40s to obtain sample B, remove sample B and develop in developer MIF-300 for 4 minutes to wash away The exposed photoresist obtained sample C;

[0033] Use the method of electron beam thermal evaporation or magnetron sputtering to directly plate a gold film with a thickness of 20 nanometers on the surface of sample C to obtain sample D; place sample D in ac...

Embodiment 2

[0037] Based on the n-type silicon wafer with (100) crystal orientation and resistivity of 5Ωcm, place the silicon wafer in deionized water and acetone in sequence for ultrasonic cleaning for 15 minutes, and then immerse in piranha washing solution at 60°C After 10 minutes, take it out and dry it to be sample A. Spin-coat photoresist AZ5206 on the surface of sample A, and form a photoresist layer with a thickness of 300-500 nanometers after drying; it is made in the form of a silicon micro / nano wire array Contact mask, using a contact mask with silicon micro / nano wire array patterns to expose the photoresist layer to UV for 40s to obtain sample B, remove sample B and develop in developer MIF-300 for 4 minutes to wash away The exposed photoresist obtained sample C;

[0038] Use the method of electron beam thermal evaporation or magnetron sputtering to directly plate a gold film with a thickness of 20 nanometers on the surface of sample C to obtain sample D; place sample D in ac...

Embodiment 3

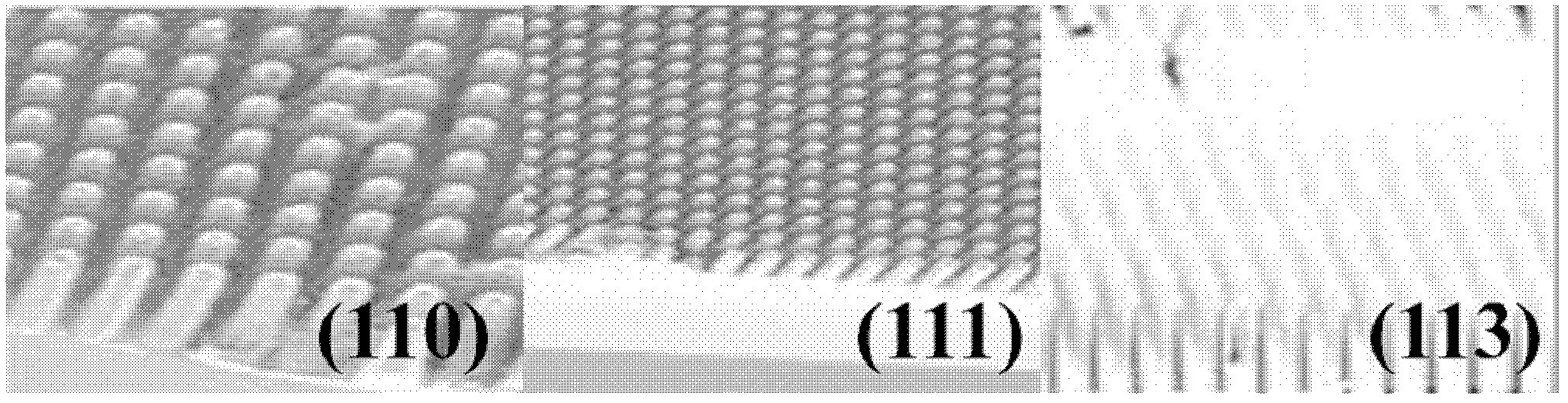

[0043]Based on n-type silicon wafer with crystal orientation of (100) and resistivity of 12 Ωcm, the silicon wafer was placed in deionized water and acetone for 15 minutes of ultrasonic cleaning, and then immersed in piranha washing solution at 60 °C After 10 minutes, take it out and dry it to be sample A. Spin-coat photoresist AZ5206 on the surface of sample A, and form a photoresist layer with a thickness of 300-500 nanometers after drying; it is made in the form of a silicon micro / nano wire array Contact mask, using a contact mask with a silicon micro / nano wire array pattern to expose the photoresist layer to UV exposure to obtain sample B, remove sample B and develop in a developer for 4 minutes to wash away the exposed photoresist Adhesive sample C;

[0044] A gold film with a thickness of 20 nanometers is directly plated on the surface of the sample C by means of electron beam thermal evaporation or magnetron sputtering to obtain a sample D; the sample D is placed in ace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com