Preparation method for orderly silicon nanowire array

A silicon nanowire and orderly technology, applied in the field of nanomaterial preparation and application, can solve the problems of high cost and low efficiency, and achieve the effect of low cost, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

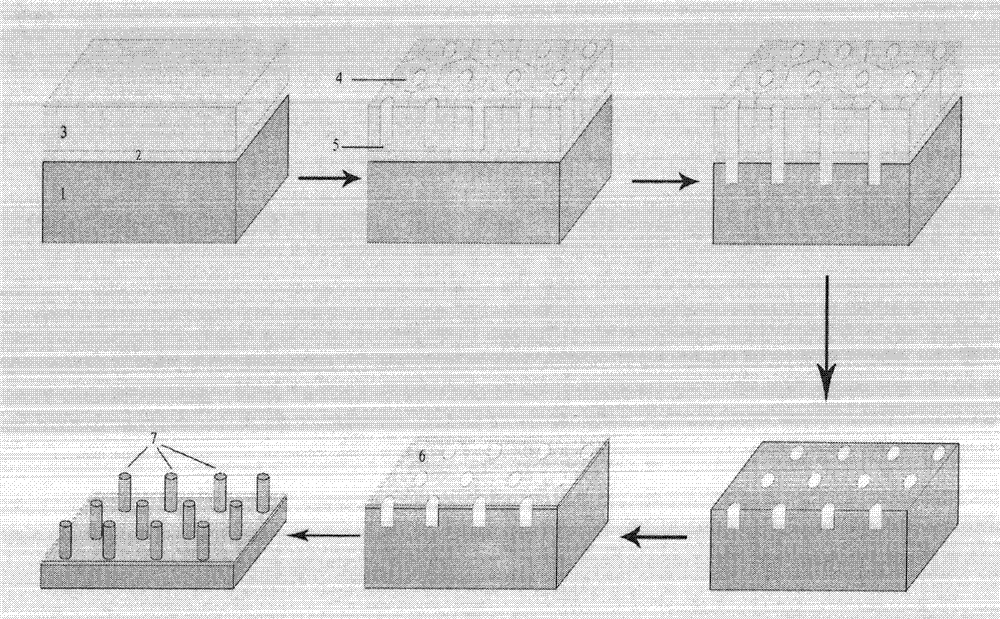

[0022] Refer to the attached figure 1 The specific steps of the method of the present invention are described in detail.

[0023] (1) Select a suitable silicon substrate 1 and perform ultrasonic treatment on the silicon wafer with acetone and ethanol respectively to remove surface contamination and organic matter. Further, concentrated sulfuric acid and hydrogen peroxide solution are used to clean the silicon wafer, and after rinsing with deionized water, dilute hydrofluoric acid solution is used to remove surface oxides, and then rinsed repeatedly with deionized water.

[0024] (2) Deposit a layer of silicon oxide 2 with a thickness of 20-80 nm on the cleaned silicon surface by using plasma chemical vapor deposition equipment.

[0025] (3) Deposit aluminum film 3 with a thickness of 200-500nm on the surface of silicon oxide by thermal evaporation or electron beam evaporation, and the background vacuum of the cavity is 2-8×10 -4 Pa, the initial deposition rate is about 0.1n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com